When it comes to carbureted hot rods, it’s often assumed that poor fuel economy, emissions and drivability are compromises we must make in order to gain performance. But in reality, these goals are not conflicting. Who says you have to drown the engine in fuel at part throttle, in order to satisfy the engine’s needs at full throttle? Whether you’re at idle or wide open throttle, efficiency is what you want. We’ll dig into carburetor and ignition adjustments that will help you achieve that, but first let’s take a look at a few other areas that can affect fuel economy.

Volumetric Efficiency

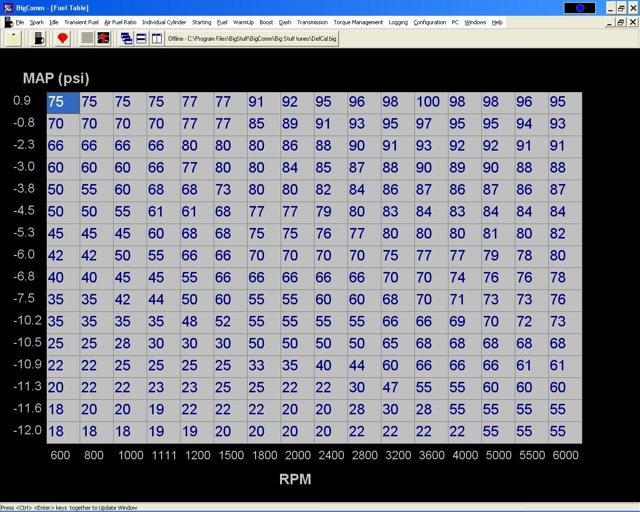

Volumetric Efficiency (VE) is defined as the amount of air (in percent) that your engine ingests at any given time, compared to the engine’s theoretical maximum capacity. Any time we can increase the VE of the engine, it will make more torque at that point. If you can increase torque without having to increase throttle position, performance and mileage will also improve.

This 650 horsepower small block Chevy requires a large, low-restriction air filter to keep up with airflow demands.

On a basic level, an engine is just an air pump. And like any other pump, there is an intake and an exhaust. To minimize pumping losses, there should not be any restrictions on either end. Running an adequately sized low restriction air cleaner and filter ensures that there won’t be any inlet restrictions, but the exhaust side is slightly more complicated. The exhaust manifold or header length and tube diameter can change the resonance tuning of the engine and the VE at any given RPM, but any exhaust component beyond the collector is only a potential for restriction. After the headers, an exhaust system with adequate flow for the power level of your engine should only help to increase VE.

This volumetric efficiency table from a fuel injection map shows the percentage of the cylinder that's filled at different load and RPM points. Increasing VE at cruising speed improves gas mileage.

Camshaft Selection

Choosing a camshaft always involves a compromise between low-end torque and high-end horsepower. The cam specs determine where in the RPM range the highest VE occurs. An increase in duration should provide an increase in VE at higher RPM, but usually comes with a corresponding decrease at lower RPM. Since we’ll likely be cruising at lower engine speeds, the reduction in VE translates into a similar reduction in gas mileage.

Intake Selection

The intake manifold plays an important role in volumetric efficiency as well. While a single plane intake manifold with a large plenum volume helps to fill the cylinders more efficiently at high engine speeds, the reduced velocity is sure to cause a reduction in VE at lower speeds. As with the camshaft, intake selection is a compromise between low and high RPM efficiency. A single plane intake therefore has the potential to reduce VE in the lower RPM range. Again, since the engine usually cruises in this lower range, gas mileage will be reduced here as well

EGR Valve

The Exhaust Gas Recirculation valve is commonly removed to clean up the engine bay. While most enthusiasts know that it’s designed to reduce emissions, what is seldom known is that it also increases gas mileage. Since exhaust gases are only recirculated during cruise speeds, the valve has no effect at idle or wide open throttle. When recirculated, the inert exhaust gases takes up some room in the cylinder, leaving less available space for the fresh air/fuel mixture to enter. Two things will now happen. First, the engine makes a little bit less power, which requires the driver to open the throttle slightly more to compensate. This further unrestricts the air intake path, which reduces pumping losses. Second, it reduces the mass of usable air in the cylinder, which decreases engine load and allows for a slightly more advanced ignition timing lead. The combustion chamber temperature is drastically reduced during EGR, which is a big help for high compression street cars.

Torque Converter

Torque converter selection also has a noticeable effect on mileage and performance. The converter has two jobs: transfer engine torque at higher RPM with minimal slippage, and multiply torque at lower RPM by allowing some slippage to take place. We want to keep the engine in it’s power band, between peak torque and peak horsepower, as the car goes down the track. But while cruising around, keeping the torque converter from slipping improves mileage considerably. This is where a converter with an electrically controlled “lockup” clutch really shines. Selecting a torque converter and rear axle ratio that reduce converter slippage yields improved economy.

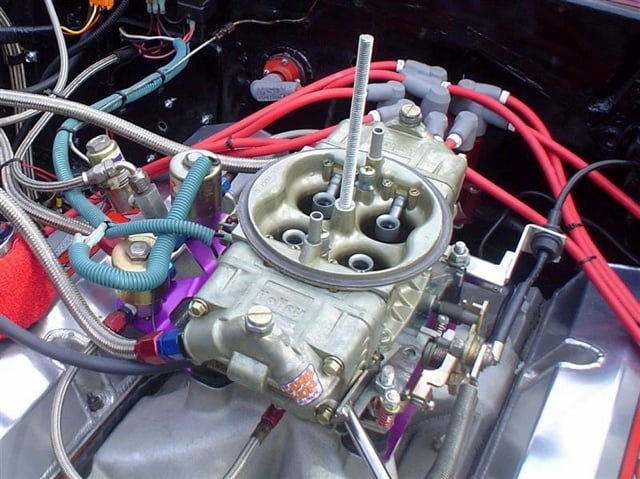

The 950 CFM Holley HP Series carburetor comes with removable air bleeds and four-corner idle circuitry to make tuning easier.

Carburetor

The carburetor itself has perhaps the most pronounced effect on fuel consumption. Since each carb comes pre-calibrated for a certain cubic inch and RPM range, the best place to start is with the right size carburetor. You can calculate the required CFM using the following formula:

Theoretical Carburetor CFM = (Engine CID * Maximum RPM) / 3456

This formula assumes 100% volumetric efficiency at redline, but street motors are more likely to fall in the range of 80 – 95%, depending on head/cam/intake/exhaust selection. Therefore, we should factor that into the equation by using an additional formula:

Required CFM = Theoretical CFM * Estimated Engine VE%

Now that we know the required amount of airflow, the next decision is whether to use a vacuum secondary carburetor or double-pumper design. For drag-race-only applications, a double-pumper will help the car launch harder at the track, but if the vehicle is primarily used on the street, the vacuum secondary is often a much better choice. Lack of secondary accelerator pump shot and a delayed secondary opening will increase fuel economy. The vacuum secondary carb’s fuel calibration is usually more efficient as well. In either case, make sure the idle and main air bleeds located on the top of the carburetor remain clean and unrestricted.

Idle

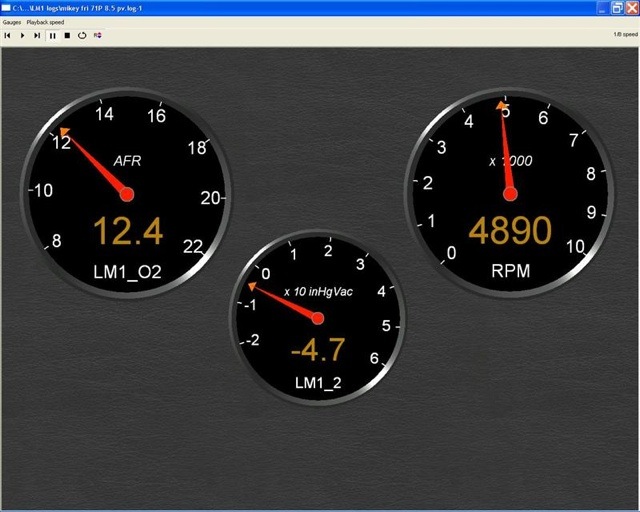

Now that we have selected the right carburetor, we can dig into tuning it. The most accurate method to tune a carburetor is with a wideband air/fuel ratio meter. They use an oxygen sensor in the exhaust stream that can accurately gauge the air/fuel ratio of the engine at any given time, which allows you much more precise adjustment. Before beginning, make sure the floats are adjusted properly, as this can affect the air/fuel ratio. On a Holley, the fuel level should be at the bottom edge of the sight plug hole.

Even race cars can have decent idle quality. This low 10 second car idles very well, despite having a large roller cam.

Next, warm up the engine and adjust the idle mixture screws until the highest sustainable vacuum reading and engine RPM are achieved. Adjust both screws in even increments, beginning with two turns out. At idle, you want an air/fuel ratio of around 14.7:1 (lambda 1.00) for standard gasoline. Some engines with larger camshafts may need additional enrichment, due to the dilution of the intake charge. In this case, you can go as rich as 13.5:1 (lambda .92).

Idle Feed Restrictors (circled) limit the total amount of fuel available to the idle and transfer slot circuits.

Make sure that your idle speed adjustment screw is set low enough that the primary throttle plate doesn’t uncover more than .060-inch of the transfer slot, as viewed from the bottom side of the throttle body. If the transfer slot is uncovered, it will richen up the mixture considerably at idle. Some engines with large camshafts require more air at idle than is provided with this idle speed position. If this is the case, drill a small hole in each of the primary throttle plates. If you still can’t get engine speed high enough to idle, repeat with the secondary throttle plates. You can also enlarge the holes some if necessary. In the end, the throttle blade must close far enough to prevent the off-idle and main jet circuits from engaging prematurely. Once you have the idle speed screw adjusted correctly, recheck the idle mixture screws.

Transfer slots (circled), viewed from bottom of carburetor, must be nearly concealed by closing the throttle plates. When opened too far at idle, a rich condition will result.

Transfer Slot

At speeds just above idle, the tranfer slot now begins to kick in. This circuit feeds the motor between idle and roughly 2000 – 2500 RPM. With a steady throttle position, the engine should want an air/fuel ratio of 14.7:1 (lambda 1.00). Again, some engines with larger camshafts may need slight enrichment here as well, but perhaps not as much as at idle. Idle feed restrictors control the amount of fuel through this circuit, while idle air bleeds control the amount of time this circuit remains on. If it stays on too long, it can overlap with the main jet circuit, causing an over-rich condition.

Main Jetting

Contrary to popular belief, the main jets are designed to control the air/fuel ratio of the cruise circuit, not wide open throttle. This covers an RPM range from around 2000 – 2500 and up, starting up as the transfer slot begins to fade out. Again, test in steady state by holding a steady throttle position. Record the air/fuel ratio in 500 RPM increments starting at 2000 RPM, and work upward until you feel comfortable. Shoot for an air/fuel ratio of 14.7:1 (lambda 1.00) by changing main jets. Leaning the engine out further increases NOx emissions and temperatures, without producing much better results.

Bottom-side view of a Holley venturi. Fuel is pulled from the fuel bowls, through the main jets and power valve channel restrictions, by a low pressure zone created by the booster venturi.

Power Valve Channel Restrictions

At throttle positions over half throttle, the reduction in manifold vacuum should cause the power valve to open. This uncovers two small fuel passages in the metering block called PVCRs (Power Valve Channel Restrictions). These passages provide additional fuel for power enrichment during heavy load situations. Since optimal main jetting was already determined, any additional fuel increase or decrease must result from a change in PVCR size. At WOT, shoot for an air/fuel ratio of around 12.5:1 (lambda .85) for naturally aspirated engines. The front side of the carburetor can be tuned separately from the back by disconnecting the secondary linkage and wiring it shut, so it cannot get sucked open. One word of caution about doing this – the engine will make more vacuum at WOT than usual. Temporarily install a power valve with a rating higher than the amount of vacuum your engine now produces at WOT. You may find as much as 5 – 6 inches of vacuum at full throttle when only running on the primaries.

The Power Valve Channel Restrictions (arrows) are blocked off by the power valve, until manifold vacuum drops below the power valve rating.

While tuning the air/fuel ratio at WOT, spark advance should be temporarily retarded to several degrees lower than your anticipated total timing. This is done to keep things safe while dialing in the air/fuel. We’re only tuning the fuel curve at this point, so maximum power production is not yet a concern. Ignition advance will be tuned separately at a later point.

Power Valve

Power valves should be sized to open after half throttle. If your engine produces, say, 16 inches of vacuum at cruise speed, then giving it half throttle should drop engine vacuum to around 8 inches. In this case, a power valve of around 6.5 should work. Generally speaking, around 2 inches less than your minimum vacuum at idle should also work out about right for a hot cam. Once the primaries are tuned in and the power valve size is selected, hook up the secondary linkage and run the engine at WOT again. Now any deviation from the desired air/fuel ratio at WOT can be adjusted by changing secondary main jets.

Accelerator Pump

Now that we have tuned in the idle, transfer slot, main jets, PVCRs, and power valve, we can focus our attention on transient fueling. On double-pumper carbs, the secondary linkage should be disconnected again, while the primary accelerator pump is tuned by changing pump cam position, pump cam, and squirter size. Target a transient air/fuel ratio that is slightly richer than your current target air/fuel ratio. For part throttle, this might be around 13.8:1 (lambda .94). At full throttle, try to maintain your target WOT ratio of 12.5:1 (lambda .85) without any momentary lean spikes. With the primary pump now tuned, hook up the secondaries and repeat the procedure for the back.

Spark Advance

After getting the air/fuel ratio correctly dialed in, we can now move on to the real power builder – ignition timing. Beginning with around 8 degrees lower total timing than expected, run the car on the dyno or at the drag strip and note the average power or MPH results. Traction issues must be removed from this equation in order to obtain meaningful data. Let the car cool down for a little while, and then run it again, adding 2 degrees of total timing. Note the results, and repeat the procedure until the engine does not pick up any more power or the car does not pick up any more MPH. What we’re looking for are the big increases. If the results are the same or worse, back up to the last setting.

During these tests, spark knock MUST be completely avoided at all times. You can listen for knock by ear, or with “det cans” or chassis ears hooked to the motor. An aftermarket knock sensor setup can also be used, and spark plugs should be read for signs of detonation along the way. We want as much timing as possible, as long as it adds power or MPH without knocking. An additional margin of safety is also a good idea, in case you run across a bad tank of gas in the future, or better weather than what you tuned for.

Tuned to Perfection

Now that you have picked out the right parts that work together as a combination, tuned the carburetor for the proper air/fuel ratio in all scenarios, and found the optimal spark advance settings, the engine should perform really well. The byproduct of this newfound efficiency is an increase in gas mileage, drivability, and most likely a reduction in emissions as well. Apparently, you can have your cake and eat it too.