Just like a human needs blood to pump through our hearts, BlownZ needs an abundance of oil to pump through its mean ProCharged 388ci LSX resting between the fenders. We have veins and a heart to keep our blood moving throughout our body, but BlownZ has an awesome and yet intricate dry sump oiling System from Peterson Oil Systems along with Royal Purple XPR fluids through it’s lines to keep it alive and healthy.

Just like a human needs blood to pump through our hearts, BlownZ needs an abundance of oil to pump through its mean ProCharged 388ci LSX resting between the fenders. We have veins and a heart to keep our blood moving throughout our body, but BlownZ has an awesome and yet intricate dry sump oiling System from Peterson Oil Systems along with Royal Purple XPR fluids through it’s lines to keep it alive and healthy.

If you’ve been following the BlownZ Saga – you know that we have our shop gurus, Sean and Dean working day in and day out on our 2002 Camaro to get it ready for competition in the NMCA 275 Drag Radial class. We need a high-performance system that can deliver oil to every necessary line and part that needs lubrication to do it’s job, while not getting in the way and actually robbing us of power.

A dry sump oil system makes perfect sense in a dedicated drag car like BlownZ. We want to keep the windage and parasitic power losses to a minimum – and that’s just what a dry sump will do for us.

Why Use a Dry Sump Over A Wet Sump System?

So, why exactly did we make the choice to go with a dry sump over a traditional wet sump oil system? The first reason is one that you might expect: more power. Within a dry sump system, there is much less windage in the crankcase, less drag on the crankshaft as it slogs through the oil, which translates into less parasitic loss. It’s just another way we can help the 388LSX to achieve well over 1,100 horsepower at the rear wheels.

A second reason is that a dry sump system will offer us better overall oil control under the extreme conditions our LSX will see as we shoot for 7-second ETs. In some instances with a wet sump system, the g-forces from a hard launch can plaster the oil supply against the back wall of the oil pan, leaving no oil around the pump’s pick-up. The result is a big fat “0” on your oil pressure gauge – not a good situation to be in as you send your engine screaming to the redline. Since the dry sump system uses a large external tank, it can always maintain a steady supply of foam-free oil to the engine.

BlownZ’s Dry Sump Oil System

- Peterson 7″ Drag Tank Dual Return w/Catch Can: Part No. 08-0784-CC

- Peterson 5 Stage R4 Drag Dry Sump Pump: Part No. 04-5062

- Peterson 90-Degree -12 AN Inline Scavenge Filter: Part No. 09-0408

- Peterson -12 AN Pan Mount Inline Scavenge Filter: Part No. 09-0404

- Peterson Oil Tank Heater: Part No. 08-0300

- Peterson Inline Oil Temp Sender Housing: Part No. 09-1875

- Peterson Remote Filter Mount w/Primer Pump: Part No. 09-1571

- ARE LS Engine Dry Sump Oil Pan: Part No. 1004M

- Royal Purple XPR Fully Synthetic 10W-40 Race Oil

And our third consideration is packaging. While the dry sump system may seem more intricate to plumb and actually takes up more physical space, it ends up being much easier to use in a lowered car with less ground clearance. The dry sump oil pan is very shallow which lessens our ground clearance concerns, and can also allow the engine to be mounted lower in the engine bay for better weight transfer and driveline angles.

For the oil system in BlownZ, we turned to the pros over at Peterson Fluid Systems. Peterson was founded 27 years ago in Colorado by racers. Peterson started out as a small operation, but today they are a massive company that does 95% of their machining and fabrication in house, using CNC machining, CAD CAM designing as well as operating a full fabrication facility. Peterson has supplied winners in everything from NASCAR to professional drag racing.

Peterson Dry Sump Oil Pump

We spoke with Wade Moon, a technical expert at Peterson, who gave us the low down on the inner workings of the dry sump system on BlownZ.”In order to run an efficient drag car, obviously you need to have a tough oil pump that can do it’s job and do it well,” says Moon. On BlownZ we used the extremely lightweight five stage R4 drag race pump from Peterson (Part No. 04-5062). The five stage pump is a four lobe twisted rotor design that flows 30 gallons per minute, and as an added bonus it crates excellent vacuum in the crankcase.

Here you can see just why the external belt driven Peterson oil pump is called a “five stage”. The pump scavenges oil from a total of five different spots in our ARE dry sump pan, and redistributes it back to the tank and on to the vital parts of the engine.

Moon tells us, “The five stage drag race pump produces a lot of vacuum pull on the engine’s crankcase – which in turn, helps release those extra ponies.” In a high RPM engine, there needs to be more oil pressure in order to maintain a thin layer of separation between the bearings and journals. In particular, the five stage pump can pull anywhere from 40 PSI to 80 PSI – depending on what exactly is needed at the time. After all, every circulatory system needs a strong heart.

Peterson Pre-Filters

Filters on a dry sump system are an absolute must – you need to protect your blood, sweat, tears and money put into your powerplant. Pre-filters are best placed on the scavenge lines of your dry sump system before the oil pump. “On BlownZ, the pre-filter is a scavenge filter. The scavenge filter is there to stop larger particles that may be in the oil from getting into the pump first of all, but more importantly, protecting the integrity of the engine. This filter can be easily accessed, cleaned, replaced and gives you a better peace of mind that those larger chunks aren’t making their way into the crankcase,” says Moon.

We used both the 90-degree and pan mount scavenge filters from Peterson. The coarse screens in these filters will protect our oil pump from metal chunks if we ever had a catastrophic engine failure.

ARE Dry Sump LS Dry Sump Oil Pan

In a dry sump oil system, the oil pan is as vital as the oil pump and external tank. Even though it’s no longer responsible for holding the oil supply like it would in a wet sump system, its vital function is now to recollect the oil and get it moved back out and away from the crank case. For our oil system we went with ARE’s dry sump oil pan for LS Engines (Part No. 1004M). ARE’s dry sump pans have been widely used Indy Cars, at Daytona, and even on Corvettes running at LeMans. Dry sump oil systems are all they do, and they do them well.

The Peterson -12AN pan mount and 90-degree pre-filters were a perfect match for our ARE dry sump oil pan.

In a dry sump system, once the oil has left the moving parts- it’s done it’s job. You need to get it out of there. -Gary Armstrong, ARE

We talked with Gary Armstrong, owner of ARE to get more info on their LS dry sump pan. “In a dry sump system, once the oil has left the moving parts- it has done its job. You need to get it out of there so it’s not hanging around and causing parasitic loss,” Armstrong says. “When we designed this oil pan, we focused on the science behind all the forces acting on the oil inside the engine, and did weeks of testing on the dyno. We came up with a super efficient windage tray design that keeps the oil trapped and lets the oil pump do its job of pulling the oil away from the pan.”

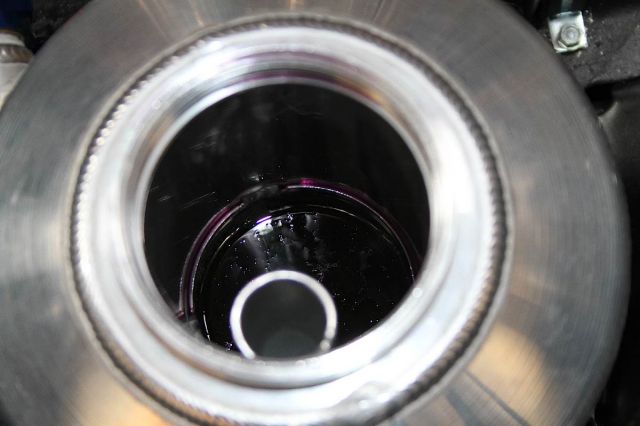

Peterson Seven-Inch Drag Tank

Aeration is the enemy of engine oil. Air contamination in oil can lead to a multitude of lubrication problems – all of which can lead a huge, slick mess as you tear down your engine for a rebuild. Peterson prides themselves on their dry sump tanks, all of which are designed to help stop air from mixing in with the oil. Internal baffles keep the oil in the tank while letting any trapped air escape. BlownZ is equipped with Peterson’s seven-inch drag tank (Part No. 08-0784-CC) with their external catch-can option.

The F-bodies already have a cramped engine bay, and with a big ProCharger taking up even more space, we had to get creative with where we mounted our Peterson Drag Tank. We found a perfect spot right in front of the driver’s side wheel well.

Moon tells us, “The drag tank does one heck of a job removing air from the oil which prevents foamy oil. This tank is specifically designed to keep an abundance of oil around the pick up to prevent spikes in oil pressure when launching the car hard at the track. It also has a built in breather – due to the internal design of the tank, it doesn’t allow oil to blow into the breather can.”

Oil Tank Heater

Cold starts are one of the most taxing events on a race-engine. Naturally, engine oil is thicker when it’s cold, and won’t have the same flow characteristics, and has a harder time making its way to all those vital moving parts. That is the exact reason we decided to also run a Peterson tank heater (Part No. 08-0300) in BlownZ’s dry sump system.

“The tank heater is exactly what it sounds like – a heater that warms the oil tank,” Moon explained, “The tank heater simply pre-heats the tank to warm the oil and ensure that the oil is at the proper viscosity at start up.”

Peterson’s Tank Heater bolts right into the bung on the tank and uses an external cord that we’ll plug in in the pits or staging lanes to keep the oil the right temperature.

Inline Temperature Sender Housing

You always have to consider “what if” – especially when you have a serious drag car, and knowing how the exact temperatures and pressures of your oil can help you get a grasp on any small issues before they become huge problems. So for us, adding a Peterson inline oil temp sender housing (Part No. 09-1875) was a no-brainer. “Drag cars typically don’t have issues where the oil and oil pump will be running too hot, but having an easily accessible port where you can check the temperature, just in case, can be reassuring,” says Moon.

The Peterson inline oil temp sender housing make tapping into BlownZ's oil lines for temperature readings a breeze.

Remote Oil Filter Mount With Oil System Primer

Priming a race engine is extremely important. You want to make sure that every internal component has just the right amount of oil before things really get moving. Why is this important? Primed engines almost always show fewer signs of premature wear in comparison to engines that have not been primed. On the BlownZ Project, we chose a Peterson Remote Filter Mount with a Primer Pump (Part No. 09-1571).

The Peterson remote oil filter housing is where we'll mount our main oil filter for easy access. Equally important to us is the ability to prime the engine and get the oil flowing before we start it up.

Fragola 3000 Series Lines

Oil Lines: Fragola Series 3000 Hose and Fittings

- -12AN x 90° Series 3000: Part # 109012-BL – Qty 5

- -12AN x 45° Series 3000: Part # 104512-BL – Qty 5

- -12AN Straight Series 3000: Part # 100112-BL – Qty 5

- -12AN Radius Fitting For Vacuum Pump: Part # 495641-BL – Qty 5

- 20 Feet of -12AN Series 3000 Hose: Part # 720012

“The remote filter catches the much finer particles, much like a regular oil filter on a wet sump system on an everyday car,” explains Moon, “but the special part about this part of the dry sump system is the fact that the entire engine can be properly lubricated in just seconds with this primer pump.” What this means is that we can take BlownZ to the track, attach a 7/16″ socket to a handheld drill and within ten seconds, have all the moving parts of our LSX properly primed and lubricated before we light the fire.

For the veins of BlownZ’s circulatory system, we used Fragola’s Series 3000 braided stainless race hose. Both an inner and outer layer of stainless mean that the Series 3000 hoses won’t collapse and can handle up to 1,500 PSI, in addition to being abrasion resistant. We specifically picked the Series 3000 lines because of both their durability and ability to handle most any fluid we might run through them, or drip on them.

“The hose ends I can tell you are made 6061 aluminum. Our Series 3000 hose ends have a unique one-piece design that eliminates two brazed joints typically found in other hose ends,” says Fragola’s Jeff Stacy. “Two Viton O-rings form a redundant seal to ensure a no-leak service. Also, there is a stainless steel lock wire to prevent galling in the nut.”

We used Fragola’s Series 3000 Braided Stainless Race Hose for all of BlownZ’s cooling, fueling, and oiling plumbing. We matched the hose with Fragola’s Series 3000 billet swivel hose ends.

The Fragola Series 3000 hose ends use a unique one piece design that eliminates two braised joints, and feature two Viton O-rings

Royal Purple XPR Race Oil

What good would a trick dry sump oil system be if we used junk oil? Of course, we reached out to our friends at Royal Purple to set us up with some of their XPR (Extreme Racing Performance) oil before we hit the dyno and race track. Chris Barker, who is the expert on XPR fluids, was able to give us some insight as to why XPR is a good fit for our high RPM LSX in BlownZ.

After all this hard work, there’s no way we’re trusting our engine to just any old off-the-shelf oil. For us, Royal Purple’s XPR 10w-40 Race Oil was just what we were looking for to keep our engine healthy and not cost us power.

“We have not cut any corners while formulating our racing oil,” Barker states. “We have made sure that XPR is a fully formulated, incredibly stout oil that will not dirty the inside of your engine by leaving deposits, which makes XPR completely different from other racing oils in the racing industry.”

Why is XPR our choice for BlownZ? It offers a great viscosity safety margin, works well with a variety of exotic racing fuels, and is very robust. “XPR is a great choice oil for a non-Top Fuel race car because not only does it keep your engine clean, but it is also full of anti-wear additives and is made for long term use. The Synerlec Additive Technology helps prevent contact between metal parts which directly reduces friction and heat. That means more power to the wheels,” says Barker.

In Conclusion…

With all the engine and chassis tuning we’ve done over the last few months, it was nice to know we had one less thing to be concerned about. We confidently sent our 388ci LSX to the redline over and over again, and knew it was always properly oiled and primed by a top notch oil system. We have already eclipsed low 8-second quarter mile times and 7s are right on our finger tips. Stay tuned for more updates on Project BlownZ as we keep fine tuning and reaching for lower ETs!