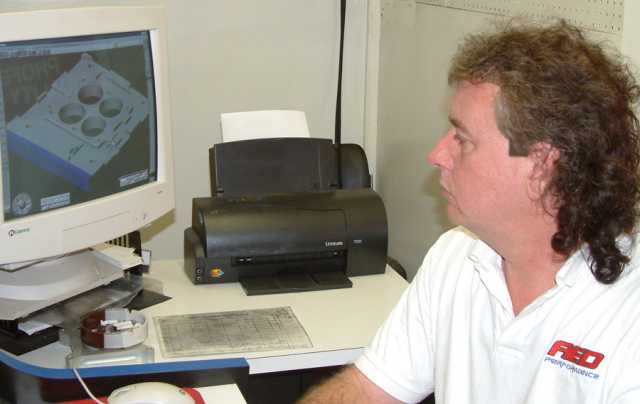

About John Dickey and AED Carburetors

AED Performance was founded with one basic premise in mind; manufacturing of high quality components at competitive prices. Their background includes over two decades in the automotive aftermarket field in design, building, and research and development of high performance components. AED manufactures a complete line of fuel system components, including carburetor kits, billet & birchwood spacers, CNC billet metering blocks & billet baseplates, and replacement parts. Their R&D facility consists of 3 flowbenches, Mustang dual eddie current chassis dyno, Superflow engine dyno, test engines, CAD-CAM design modeling equipment, and complete CNC machining facility.

Choosing the Right Carburetor

Picking the right Carburetor size for your car & engine combination is paramount in being successful – whether you’re a professional racer or just want the right carburetor for you’re Saturday night special. There are three main parameters that correctly determine your baseline selection. From there you need additional information to fine tune that selection. Let’s start with the big 3.

1 – Cubic Inches

First on the list is cubic inches. Simple parameter for total cubic inches, including any additional bore and stroke.

2- Next is Total RPM Range:

Here you need to know both the minimum and maximum RPM range. Minimum rpm is just as critical as maximum rpm. Foremost, you need to be concerned with the minimum rpm that you have to accelerate from. Several additional pieces of information come into play here – such as transmission type, and converter flash rpm. For example, the exact same engine in a car with a 3500 rpm stall converter will want less carburetor than one with a 5500 rpm stall converter.

Here you need to know both the minimum and maximum RPM range. Minimum rpm is just as critical as maximum rpm. Foremost, you need to be concerned with the minimum rpm that you have to accelerate from. Several additional pieces of information come into play here – such as transmission type, and converter flash rpm. For example, the exact same engine in a car with a 3500 rpm stall converter will want less carburetor than one with a 5500 rpm stall converter.

It’s all about acceleration – a larger carburetor that might make more torque & power on the dyno will usually run slower ET’s if the engine can’t accelerate properly from the minimum rpm. Remember, engines are not happy when they run below max torque rpm! That’s why the correct converter should flash to roughly 100 to 200 rpm above max torque rpm. Gear ratios also play a role in this calculation, as the car weight does. The heavier the car or higher the gear will affect the time spent in different rpm bands. This would require a carburetor sized smaller than a lighter car, with more rear end gear (numerically higher).

Camshaft & the cylinder head (intake port volume) also plays a key role in the rpm range. In most cases the camshaft and cylinder head dictates the rpm range. Here’s where you can get confused easily. In many cases, the bigger the cylinder head (intake port volume) the less carburetor the engine wants; while assuming two similar engines with the same rpm range. A good example is a standard small block Ford & small block Chevrolet. The Ford factory head volume being smaller requires more carburetor than a typical Chevrolet. We have proven this through dyno (engine & chassis dyno) as well as racetrack testing. It comes down to port velocity & choke points (usually pushrod area on head). The induction track only wants one choke point to control velocity, which is usually the cylinder head or carburetor.

Camshaft & the cylinder head (intake port volume) also plays a key role in the rpm range. In most cases the camshaft and cylinder head dictates the rpm range. Here’s where you can get confused easily. In many cases, the bigger the cylinder head (intake port volume) the less carburetor the engine wants; while assuming two similar engines with the same rpm range. A good example is a standard small block Ford & small block Chevrolet. The Ford factory head volume being smaller requires more carburetor than a typical Chevrolet. We have proven this through dyno (engine & chassis dyno) as well as racetrack testing. It comes down to port velocity & choke points (usually pushrod area on head). The induction track only wants one choke point to control velocity, which is usually the cylinder head or carburetor.

3 – Power Level

The third consideration is horsepower. A lot of the previous questions are about determining how much power your engine makes & at what rpm; now let’s get technical & crunch some numbers. Your engine needs a certain amount of airflow to reach a certain power level efficiently. From our 25 years of dyno experience, we’ve found that it takes 1 cfm to make between .7 & .8 horsepower. The more efficient the engine, the less airflow it requires to make the same power.

The basic formula for carburetor sizing & CFM consumed is (CFM = CID x RPM x VE ÷ 3456). Here CID = Cubic Inches; & VE = Volumetric Efficiency. This is just a rough estimate, as the VE number is the basic efficiency or cylinder filling of the engine. This formula should only be used as a starting point on carburetor sizing, then all the other factors we are discussing will move this number up or down. Let’s take a typical small block Chevy 383ci stroker engine that makes max power at 7000 rpm (assuming 108% VE), plug in the numbers & you get a CFM requirement of 838 on an engine that should make between 590 & 670HP – using our above formula for horsepower per cfm used.

Street motors might be 90% and a great race engine might be 120% (Volumetrically Efficient). The basic “cfm formula” can be figured out simply, but it’s just a piece of the puzzle and all of the previous observations are equally as important. We have found that you would be better off using a carburetor that flows this amount of air at a lower pressure drop (less restriction) like 1.2″ to 1.3″ of manifold vacuum at max rpm. This usually makes more power, but might affect acceleration in a negative fashion. A good example of this is a light car with a loose converter & plenty of gear – with a narrow rpm band – that might actually run better with closer to 900 cfm. This is only if the carburetor is setup correctly with maintaining the correct fuel curve & proper signal to the booster, which will sense airspeed changes efficiently. Have we confused you yet? Don’t forget all the other factors that go into carburetor selection mentioned above.

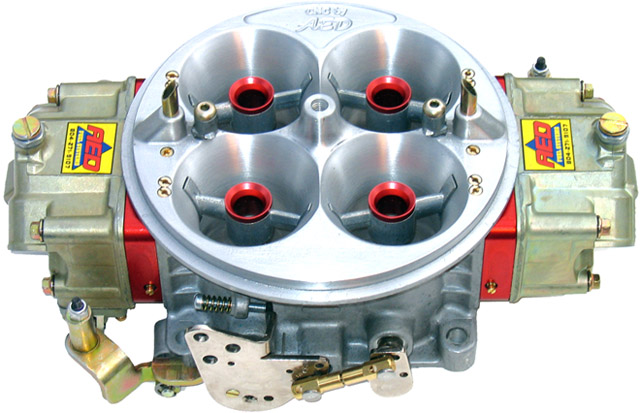

Explaining the CFM myths in more depth – Real Carburetor Airflow Numbers

Years ago the Society of Automotive Engineers provided a standard for airflow that’s still used today. For 4-barrel carburetors that number is measured airflow at 1.5″ pressure drop (manifold vacuum in inches), or used on a flow bench is 20.4″ water. For example, a 750 cfm carburetor should flow 750 (cubic feet per minute) at this pressure drop. A carburetor has fuel flowing through it, which actually displaces some airflow (usually around 8%) so this should actually be flowed with fuel or wet-flowed.

In 1990 we built our own custom computerized “Wetflow-Bench” to properly measure carburetor airflow & fuel flow. We can measure CFM, pressure drop, air/fuel ratio, pounds of air, pounds of fuel, and correct for weather conditions. We can also wetflow the carburetor throughout the entire rpm range, giving us insight to the complete fuel curve on all throttle bores. The problem comes when some carburetor manufactures do not use SAE numbers. We’ve had many carburetors through the years claiming to be one number and some would be well over 100 cfm less. Some manufactures would use 28″ of water to flow carburetors, and hence the totally unrealistic claims. We don’t play the airflow games as we feel it’s a real disservice.

Maximum Velocity Achieved

As you can see, determining the correct carburetor selection isn’t easy. It’s really part science, part knowledge, and part experience. There is no real formula for absolute carburetor size. I’ve worked on a spreadsheet for years that won’t always work. The proliferation of all the new cylinder heads and manifolds makes selection even tougher. Bottom line is always get good knowledgeable help when selecting carburetion, just like a good camshaft they can tie you’re whole program together properly & make a big difference in performance. It’s always less expensive to do it right the first time.

I hope this helps in getting a better handle on the important things to consider when choosing the right carburetor for your application. If we can be of any help we have a great tech department that can supply the correct AED Performance carburetor for your specific application & budget. Check us out at www.aedperformance.com or call us at 804-271-9107.

Sincerely,

John Dickey

AED Performance

jd@aedperformance.com