Technology has given late-model muscle cars like the 5th Gen Camaro unprecedented access to bolt-on horsepower. Unfortunately after discovering just how easy it is to add gobs of rear-wheel-horsepower many enthusiasts also find how quickly the OEM limited-slip differential’s ability to transfer torque can be surpassed. It’s about then that an age-old racers axiom is rediscovered; “The only power that really matters is the power you can get to the ground,” or put another way – “Spinning ain’t winning.”

Technology has given late-model muscle cars like the 5th Gen Camaro unprecedented access to bolt-on horsepower. Unfortunately after discovering just how easy it is to add gobs of rear-wheel-horsepower many enthusiasts also find how quickly the OEM limited-slip differential’s ability to transfer torque can be surpassed. It’s about then that an age-old racers axiom is rediscovered; “The only power that really matters is the power you can get to the ground,” or put another way – “Spinning ain’t winning.”

Luckily there are already a few performance differential options for powerful late models that see regular racing duty and need to use that horsepower and torque to get the car moving in a hurry. In fact, Eaton has even taken their respected Detroit Truetrac and adapted it for use in the new Camaros, and offers a great balance of streetability and hardcore performance. Follow along with us as we review the technical details of the 5th Gen Detroit Truetrac, and install one (Part #912A686) in a street/strip LS3 powered 2010 Camaro SS.

The Eaton Detroit Truetrac has been used in everything from daily drivers and off-road machines, to drag strip heroes and road course dominators. Now its time-proven design is available for use in the 5th Gen Camaro.

About The Eaton Detroit Truetrac For 5th Gen Camaros

Because of the Truetrac’s durability and versatility, you’ll find it used in all different types of racing and high performance applications.” -Barney Bwozdz, Eaton

The Detroit Truetrac is really nothing new. Its time-proven operation has been the same for decades, but has been steadily refined by the engineers at Eaton as new technology has allowed. “The 5th gen Truetrac is essentially the same internally as what you might find installed in a 12-bolt in a ’69 Camaro running at the drag strip,” says Eaton’s Barney Gwozdz. “This is just the design specific to the envelope GM gave us with the 5th gen Camaro’s differential.”

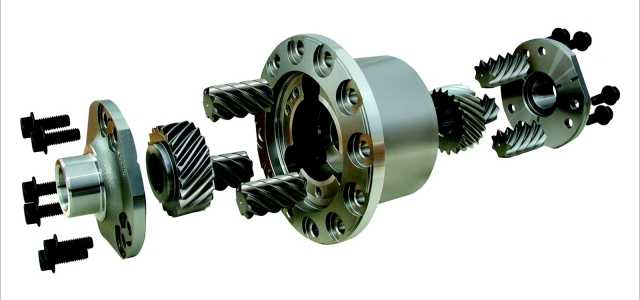

Instead of using clutch packs like a typical limited-slip differential, the Truetrac uses a helical gear design to transfer the engine’s torque equally to both wheels, or to the wheel with the most traction should tire spin occur. “The Truetrac has the ability to transfer up to 70% of the torque load to the wheel that has the most traction,” says Gwozdz. “Let’s say you have one rear wheel on wet grass, and the other on dry concrete and you rev up the engine and sidestep the clutch. Obviously there is zero rolling resistance on the tire in the grass and it is just going to spin. However, because of the Truetrac’s biasing capabilities it will send 70% of the torque to the wheel on the concrete and move the car forward.”

Inside the Truetrac are three sets of interlocking pinion gears that span from one main axle gear to the other. The gears will be completely locked up when both tires have the same amount of traction, but will still seamlessly allow the outside wheel to spin faster as the car goes through a turn on the street or a road course. No popping, clunking, or jerking. Check out the video below for a visualization of how the Truetrac’s helical gears operate.

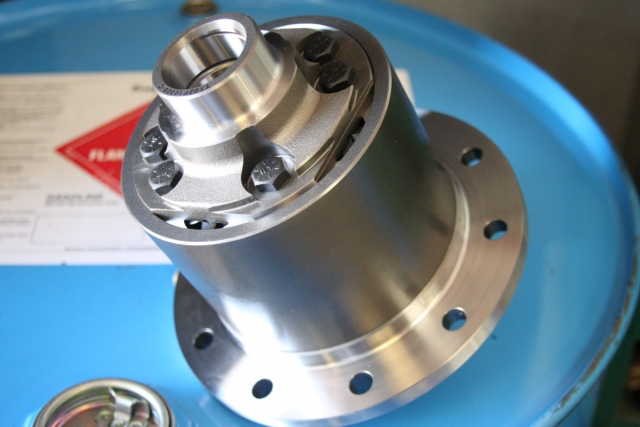

The Truetrac is at home on the street, but it is built durable for racing. “What we try to do is add as many pinion gears as we can inside the envelope we have been given to work with,” says Gwozdz. “The more pinion gears you have, the better they can dissipate the torque load. The 5th gen Camaro Truetrac is a three-pinion design so it’s very heavy-duty.” Eaton continues the heavy-duty design on the outside of the Truetrac as well. They wrap the helical gears in a rigid steel case, rather than a typical sand-casting to ensure that everything stays together even under the rigors of racing. Here's a side-by-side comparison of the 5th gen Truetrac (left) and and a '69 Camaro 12-bolt Truetrac (right). They are very similar other than size, which is specific to each application. Also notice the hole in the case of the 12-bolt Truetrac for access to the axle c-clips.

5th Gen Specifics

5th Gen Camaro Eaton Detroit Truetrac

- Three Pinion Helical Gear Design

- Durable Hardened Steel Case

- Works with Stock or Aftermarket 31-Spline Axles

- Locks Wheels Together in Straight Line

- Automatically Transfers up to 70% of Torque to Wheel with the Most Traction

- Street Friendly and Quiet Operation

- Uses Standard Gear Oil (No Synthetic or Additives)

Eaton did have to make a few small changes to adapt the time-tested Truetrac to the new Camaro’s independent rear suspension. “The agility and articulation allowed by the new IRS is great, but it did have some special considerations in our design,” Gwozdz tells us. “For example, the pilot on the axle shaft as it enters the differential’s bearing journal is unique. So we had to make our own provisions to pilot the half-shaft into the Truetrac.”

The 5th gen Truetrac is designed to work with stock and aftermarket 32-spline rear axles, and will also accept any 218-milimeter ring and pinion set with the same flange height as the stock gear set.

Another unique consideration for the new Camaro is that it does not use synthetic gear oil like the stock differential, or any kind of friction modifier or additive for that matter. The reason for this might seem strange, but synthetics gear oil and friction modifiers are actually too slippery for the pinion gears in the Truetrac. They need a small amount of resistance to bite together properly, so Eaton designed the Truetrac to work with plain ‘ol conventional 80W-90 gear oil.

The Test Car: Street and Strip 2010 LS3 Camaro SS

The Truetrac is a perfect match for Jose Lugo’s powerful daily driven street/strip Camaro SS because of its balance of no-slip traction and smooth operation.

Our test car might look familiar to those of you who frequent our site on a regular basis; that’s because it’s Jose Lugo’s street and strip beast dubbed “Killer Bee”. The Camaro is a 2SS/RS with an LS3 that has been treated to Doug Thorley long tube headers, an Airaid MXP cold air intake, and a COMP camshaft to really wake things up. The cam specs in at 227/239 duration, .629/.623 lift, with a 114 LSA, and the whole combo puts down a very respectable 475 horsepower and 430 pound feet of torque to the rear wheels.

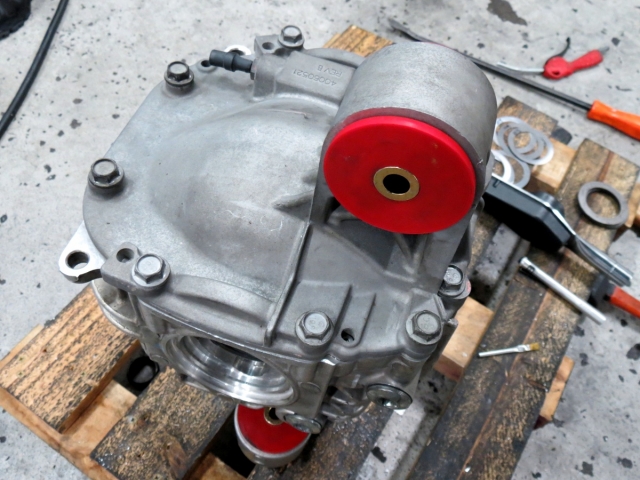

The Camaro sees a lot of drag strip duty in addition to serving as Lugo’s daily driver, and has run as quick as 12.31 at 115 MPH on drag radials. In the search for a twelve-flat timeslip, Lugo opted to have the guys at central Texas’ Easy Performance install the Detroit Truetrac along with a set of 1LE Camaro 3.91 gears and BMR’s polyurethane differential housing bushings while they were at it.

The Install Sequence

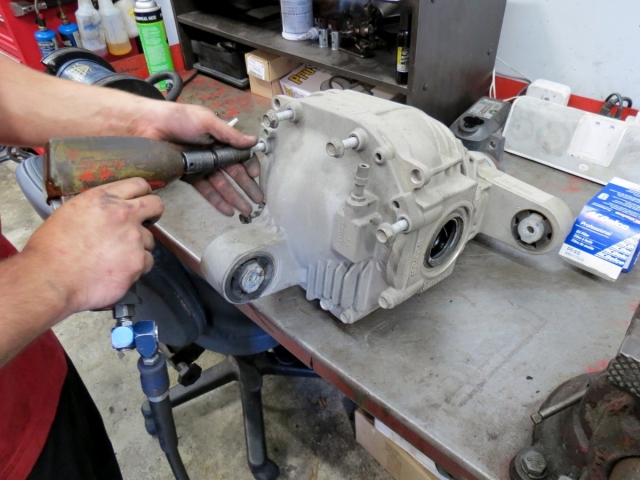

We’ll be honest with you. Installing a differential and gear set in a 5th Gen Camaro isn’t really a job for the average at-home DIY’er, unless you already have a lot of experience in the arena. It’s a job that takes a lot of special tools, lots of time, and lots of know-how. Some jobs are best left to the pros. That having been said, here are the basics of the install sequence. Getting the rear differential case out of the Camaro's independent rear suspension requires removing a lot of parts - including the exhaust, rear control arms, axles, and driveshaft.

The disassembly started with letting the diff fluid drain while removing or unbolting numerous components under the car including the wheels, exhaust, driveshaft, and rear control arms. The rear axles were removed by unbolting the outer retaining nut, and pulling the splined end out of the hub while pushing up on the rear suspension links. From there the axles were popped out the sides of the housing with some moderate pressure from a pry bar. With the axles out of the way, the three bolts that hold the diff housing to the car were removed and the assembly was easily lowered out of the car. We let the diff fluid drain while we disconnected the rear control arms and half-shafts.

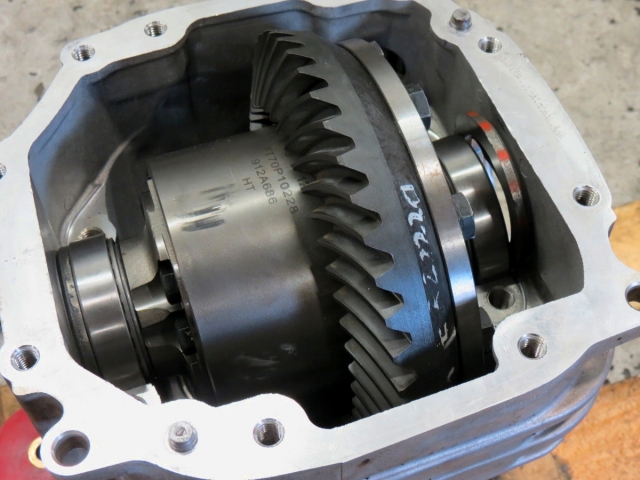

With the diff housing on the workbench the rear cover was taken off, and the differential side bearing caps were unbolted. Now, we should note that the factory service manual calls for the use of a case spreader to remove and install the differential in the aluminum housing, but we found that some pressure from a pry bar was just enough to get the differential in and out of the case throughout the install.

After everything was out of the way we removed the three mounting bolts that hold the housing, dropped out the housing, and headed to the work bench for the remainder of the install.

Getting It Together

To start the reassembly, the new 1LE ring gear was bolted on the Truetrac. The ring gear does have a slight interference fit, but ultimately it slid right on the carrier after a little heat was applied with a torch. The ring gear bolts were then tightened to 89 foot-pounds in a crisscross pattern. Getting the differential in and out of the case required some gentle persuasion from a pry bar. We got the ring gear on the Truetrac with a little heat and a few taps from a rubber mallet, and tightened everything up.

The first trip to the shop’s hydraulic press started with popping out the stock pinion from the case, and removing the bearings to get access to the stock shim stack which would be used as the starting point for the new pinion. The carrier and pinion bearings were also pressed on before the pinion was dropped in the case and the pinion yoke pressed back on.

When the Truetrac went back in the case, the stock carrier shims were reused in hopes that luck might be on our side. The backlash measured out at 0.009”, which as hard as it might be to believe was too loose. The pattern also revealed that the carrier needed shimmed to the left and that the pinion had too much shim. So the Truetrac was pried back out and the case was taken back to the press to pop the pinion out and to get the bearings back off. It took us two full rounds of shimming the pinion, checking preload, and testing backlash, but when all is said and done we ended up with a very good pattern.

The second round was much more fruitful. With the shorter pinion shim and shifted carrier shims the backlash measured out at the factory spec of 0.007”. Thee gear pattern was also right on for both sides of the ring gear – Score one for the good guys .The diff assembly was buttoned up for the final time by torquing the side bearing caps to 77 pound feet and the cover bolts to 41 pound feet before reinstalling the diff case back under the Camaro and refilling it with regular 80W-90 gear oil. With all our tests landing within spec we buttoned up the diff housing and bolted it back in the car. Done and done.

Driving Impressions: on the Street and at the Strip

So far, the Truetrac acts just like the stock differential on the street – but dead hooks [at the track]…” -Jose Lugo

Lugo drove the Camaro on the street as he normally would for about 500 miles, making sure to take his time so everything would be nice and broken in. “So far the Truetrac acts just like the stock differential on the street,” Lugo tells us. “There aren’t any weird noises, clunks or pops. The car does accelerate much better in first gear with the 3.91s, and the RPM has only jumped up by a few hundred in 6th gear on the highway.”

We’re happy to report that the good results from the 5th Gen Eaton Detroit Truetrac haven’t just been limited to its street manners. On his first trip to the drag strip after the Truetrac/gears/bushings install Lugo was able to better Killer Bee’s previous best of 12.31 by almost three tenths, running a 12.06 at 115 MPH! “The Camaro dead hooks with the Truetrac. The difference is like night and day from the stock differential,” he tells us. “My 60 foot time also improved from 1.95 to 1.90 thanks to the Truetrac and 3.91 gears.”