Nick Devenuto went to Larry Saxon’s LSX Performance and PCM Tuning in Indian Trail, North Carolina, with one goal in mind – to rework the 427-cubic-inch engine from his Camaro and get it well over the 600-horsepower mark. During dyno sessions at Prestige Motorsports, Saxon achieved the goal and then some – with more tuning left to do on the project due to a an issue discovered on the dyno.

The engine as it arrived at LSX Performance and PCM Tuning – many issues were discovered and corrected in the subsequent build.

“I have the car here in the shop right now. We’re mounting a nitrous bottle and doing some suspension modifications, as well as changing up the spark plug wires,” says Saxon. “We didn’t realize they were bad on the dyno. The dyno operator was trying to slow the dyno down because the engine accelerates so quickly due to the lightweight parts inside. By putting a longer time and pressure on the engine on the dyno, the plug wires were breaking down more and more. They were about the only part we re-used on the whole engine as they appeared fine. I went to go set the timing and that sucker bit me. I was looking for 660-670 horsepower and it made 635 horsepower and 585 foot-pounds of torque on 93 octane pump gas.”

There is a chassis dyno available at LSX Performance, but Saxon is expecting the numbers to be much different due to the high-stall converter and overall package. The engine was originally constructed by another shop as a mild 427 that didn’t perform anywhere close to what was advertised, and the deeper Saxon got involved in the project, the more parts he had to toss into the scrap heap to achieve what the customer wanted.

Mixed and not matched

“It was a new engine that someone else had built and wouldn’t get out of its own way. It probably only made 350 horsepower, it was just dead. We starting finding problem after problem, and we basically ended up where we are now,” he says.

The engine initially had a factory GM steel crankshaft in it, but upon disassembly, Saxon learned that it had been welded to fix earlier damage. A welded crankshaft with the type of horsepower the engine was expected to make simply won’t live in those conditions.

He also discovered two different style of GM “dimpled” connecting rods in the engine; some had been balanced on the small end while others had been balanced on the big end, which threw off the engine’s balance. In addition, the pistons were very heavy and not well-suited for the application. He also found that the heads were over-ported, which necessitated the use of larger valves in the new assembly, and the camshaft had lobes worn off due to the wrong spring pressure – among other problems. All of these issues taken together had him selecting a wide variety of new parts to complete the build and get Devenuto’s 1969 Camaro back on the road.

His rebuild of the engine centered around a re-worked 7.4L GM block featuring a 4.310-inch bore, a Liberty 3.76-inch-stroke 4340 steel crankshaft with 2.200-inch rod journals. The new connecting rods are from SCAT Enterprises and are 6.385-inches long, and use 4340 ARP bolts for retention. Mahle pistons found a home in the new build, as did a Melling high volume oil pump and SA Gear double-roller timing set. Compression ratio specs out at 10.0:1 for pump-gas-friendly horsepower.

The new build also changed the camshaft design from the failed flat-tappet unit to a 4/7 firing-order swap solid-roller camshaft from Erson Cams, with .680-inch lift on intake and exhaust coupled with 256/264-degrees of duration at .050-inch lift on a 110 centerline. The purpose of the 4/7 cylinder swap on the camshaft is to gain a much broader torque curve – a serious asset in a street-going engine such as this.

Another view of the engine awaiting installation. Saxon tells EngineLabs that no expense was spared during the course of the car’s build.

Erson also supplied the solid roller lifters, pushrods, double springs, titanium retainers, and valve locks. Cylinder heads are GM 188 square-port open chamber castings that have been fully ported and feature 2.250-inch intake and 1.880-inch exhaust valves. Crane roller rockers actuate the valves and are stabilized by a set of Jomar stud girdles. On top, an Edelbrock Victor Jr. port-matched intake manifold sucks fuel through a Quick Fuel Technology 1050 CFM carburetor.

With all of the previously-defined issues sorted out, the engine found it way onto the dyno, where the last issue – albeit easily fixed – didn’t present itself in a manner that was easily diagnosed at the time. Currently Saxon is lining out the rest of the build, has installed those new ignition wires, and expects to have the car making plenty of power in the very near future.

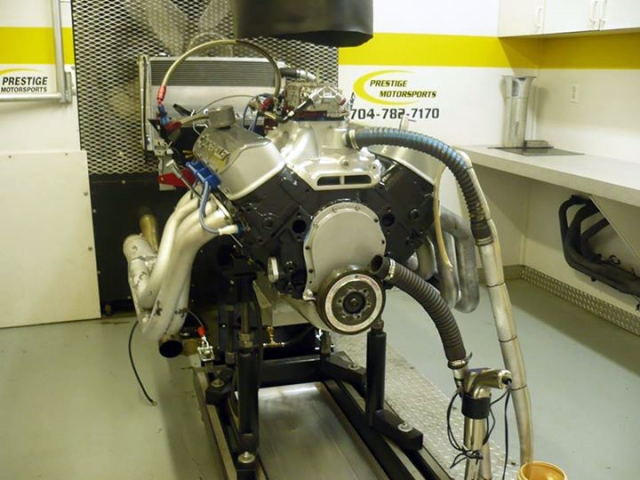

Engine on the dyno at Prestige Motorsports, where it made 635 horsepower and 585 foot-pounds of torque on pump fuel.

Tuning choices

He also has a bit of tuning left to do on the programmable ignition system and then it will be time to spin the roller on his chassis dyno in an effort to wring the power out of it. Although it won’t show on the dyno sheet, the power he tunes into it will move Devenuto’s beautiful Camaro down the street in short order.

“It revs like a circle track engine – comes right up into power. We’re using the longer rod for higher rpm power, and this engine will go to 8,000 pretty easily although it won’t be spun that high. Changing the plug wires has the engine sounding completely different than when it was on the dyno – it’s more responsive, more aggressive, and smoother-accelerating,” Saxon says.

The diagnosis of the damaged plug wires goes to show that even the experts can have issues. Now that the engine is healthy and ready to rock, Saxon expects to put a smile on Devenuto’s face before long.