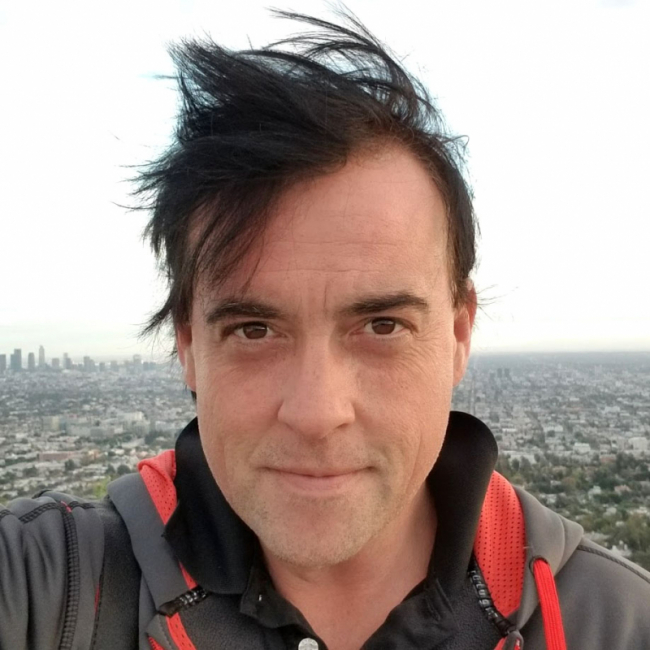

Every once in a while, we, the unwavering muscle car junkies of the world, get a chance to see how the products we know and use are actually made. While a behind the scenes video might be nothing new, Centerforce has dipped into the video content production area of the Internet. Its YouTube videos are guaranteed to ‘learn-ya’ on at least a few nuggets of clutch info. Full disclosure: we learned a couple of facts about clutch tech along the journey. So pour a cup of coffee, pull up a chair and let’s check in with “Mr. Clutch,” A.K.A. Will Baty, who still works there after all these years! We go back nearly a couple decades with Will, so we can say that, and believe us, he has forgotten more about clutch tech than most car guys even know.

Baty is an invaluable resource to Centerforce and the… driving force (pun intended) behind many of the company’s successful products. Baty offers up inside knowledge about every move Centerforce makes in its vast clutch line that might not transmit into the marketing material. While Centerforce has branched out in many areas of the automotive aftermarket, its core has always been American muscle, in every form from mild-to-wild.

“When we are developing the R&D in a clutch —throwout bearing, flywheel assembly for new applications — we want to know everything about it,” says Baty. “When we are done pulling a [OEM] clutch, it heads over to the Solid Works [design] department.”

“When we are done pulling an [OEM] clutch, it heads on over to the Solid Works [design] department." - Will Baty

All of these new applications start with market research and customer feedback on what they want in a clutch, at what power levels, and the all-important price-point — it needs to be competitive. This is where Baty and team excel at being able to identify new models, popular existing platforms with renewed interest, and various trending swaps to get them prototyped and tested right away. Because, getting to market fast is important, and as Ricky Bobby says: “If you’re not first you’re last.”

“The disc is the heart of the clutch. We hand-built this piece to ensure fitment and proper engagement,” says Baty “We manufacture and test all our own clutch materials.”

Centerforce also has a patented technology called the Dual Friction clutch disc. This patented tech features a full-face disc on the pressure plate side. There is carbon composite material on the flywheel side with multi-puck design for increased holding capacity.

Centerforce also has a patented technology called the Dual-Friction clutch disc. This patented tech features a full-face disc on the pressure plate side. There is carbon composite material on the flywheel side with a multi-puck design for increased holding capacity. Hence, the dual-friction trade name for the clutch, which is made from two very different materials to achieve one goal. The design is made to hold the rigors of street/strip performance cars for maximum holding capacity, yet maintain excellent pedal feel and control for the driver when in traffic, on the road course occasionally, or moderate drag strip runs. The patent is a win/win with this disc design according to the company’s additional Centerforce University videos.

The dual friction full-face plates, pressure plate, and flywheel are put together using premium ARP fasteners to ensure failure at that level will not be a factor.

The dual friction full-face plates, pressure plate, and flywheel are put together using premium ARP fasteners to ensure failure at that level will not be a factor.

Another process Centerforce uses is the ball bearing process seen in action on video. “The practice machines the pivot point of the clutch itself,” claims Baty. From there, the pressure plate is matched with the diaphragm assembly that is proven to ensure a quality engagement without changing the diaphragm spring at all.

The tolerances at Centerforce are very tight, and we questioned them on what level consumers are getting. “1/4-inch up to 6-inches from the center,” says Baty. “When we know we’re within that spec, there is not going to be an ounce of balance issues at all.”

Centerforce technicians perform assembly and disassembly of the clutch between 4-5 five times before it gets all buttoned-up for shipment. The QA checks are aplenty throughout the whole process and as you can see from the video a lot of hands-on checks.

Centerforce technicians perform assembly and disassembly of the clutch between 4 to 5 five times before it gets buttoned-up for shipment. The QA checks are aplenty throughout the whole process. As you can see from the video, there is a lot of hands-on assembly of the clutch with less automation, so you can assume a carefully crafted part that is going to last will be the end result.