Turbonetics is introducing a full-featured turbo for drag racers competing in the popular X275 class that limits turbos to specific dimensions.

“We offer this turbo with either an 85mm or 88mm billet compressor wheel,” says Reggie Wynn of Turobnetics. “It also comes with a 112mm turbine and ceramic ball bearings.”

Different views of the Turbonetics X275 turbo.

While the X275 is based on a T6 footprint, Turbonetics is also releasing a line of T4 turbochargers to help customers experiencing back-pressure issues.

The T4 line of turbos from Turbonetics.

The T4 family should help larger displacement engines, including LSX applications, if they’re experiencing back-pressure problems. The T4 offers all other Turbonetics features like ceramic ball bearings, full balancing on the component and assembly levels and a 1-year warranty.

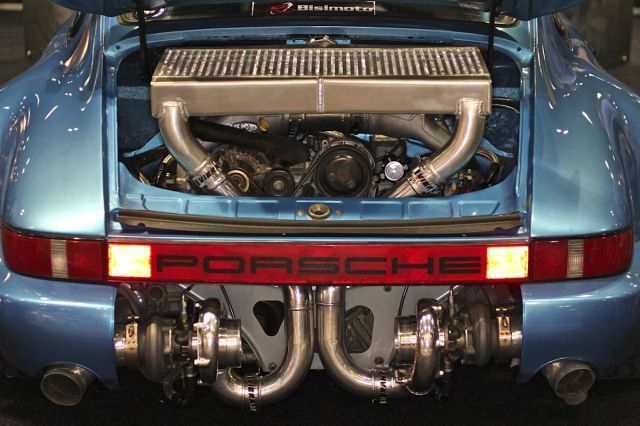

On display in the turbonetics booth was a 1976 Porsche 911 that had been upgraded with a twin-turbo engine from a 997 Porsche. It was built by Bisimoto Engineering.