American hot rodding has historically been focused squarely under the hood, namely putting the biggest engine in the smallest chassis, while letting the European and Asian car enthusiasts worry about going around corners in their underpowered, overpriced “sports cars.” Leaf springs and slapper bars were good enough to get down the 1320, and even gearheads who thought outside the box rarely did anything radical to their suspension setup. But Bret Voelkel, founder and president of RideTech, didn’t have to look far to find inspiration to improve the hard-riding suspension his contemporaries had grown uncomfortably accustomed to.

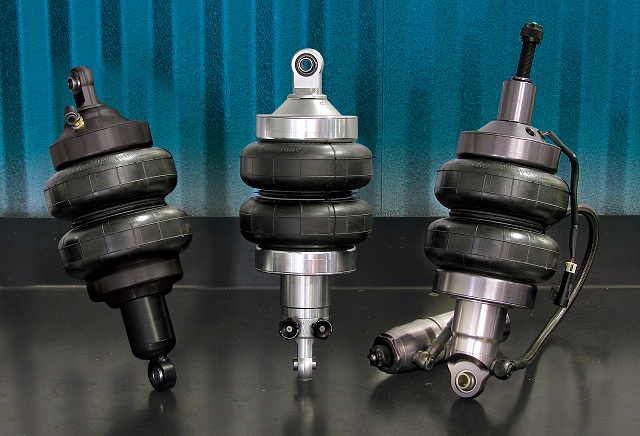

Though his company is best known for their Air Ride Technologies suspension components, RideTech has developed a product line that extends far beyond that simple beginning. They have created easy-to-use but intricate control systems in both analog and digital formats, air-over-leaf-spring suspension, anti-sway bars, shocks, and roll cages, just to name a few of the products in their extensive catalog.

Voelkel is a true car enthusiast, with an impressive collection of classic cars that he uses as test beds for his suspension products. Among his dream collection is a 1968 Camaro with a 650 horsepower LS2 engine called simply “Velocity.” Then there’s the 630 horsepower, 460-powered 1969 Ford Mustang, a 1971 Pontiac GTO convertible, and a 1970 Buick GSX, which are just the tip of the iceberg. All of them are equipped with RideTech suspensions, and all of them get driven.

The Shockwave Air Suspension is RideTech's most popular product and is entering its eighth generation.

There are a lot of advantages to riding on air, noticeably a smoother ride and direct, adjustable control over ride height. This has made RideTech products extremely popular with hot rodders looking for a true bolt-on air suspension. It has also added an unprecedented level of customization, as cars can be slammed to the ground for a show, and then driven home at regular ride height.

His company, RideTech, pioneered aftermarket air ride suspension systems for hot rodders. The technology wasn’t new or something Voelkel invented. But he did have an extremely low-riding Ford Fairmont with a conventional suspension that constantly needed to have exhaust pipes and the underbody repaired. Voelkel wanted a way to raise and lower the car at will, and he found inspiration in a place we’ve all seen but probably overlooked – big rigs. Semi-trailers have used air suspensions for decades, but Voelkel made the leap and rigged a system up to his car. It was such a wild success that he went into business for himself, forming Air Ride Technologies, now called RideTech.

RideTech is at the forefront of air suspensions, and their technology isn’t just used by hot rodders anymore. They make a wide array of products for use in everything from ATV’s to powerboats, and they are even working with the military to develop a special suspension system (which is all Voelkel could say on the matter). We still managed to pick his brain pretty good on a range of other topics, so without further ado, here’s ten questions with Bret Voelkel:

powerTV: What is your first memory of hot rodding?

Bret Voelkel: “It’s hard to say. My family wasn’t into hot rods at all – they were farmers. I guess it was in high school where I first ran across a Hot Rod Magazine. Some of the other guys at school had some cool cars and I gravitated towards that. I never had any money for anything other than basic transportation. Being a farmer, my dad always fixed his own machinery and I guess I learned from that.

My first “hot rod” was a 67 Buick Wildcat. It was a fairly nice car until I got a hold of it. I promptly blew up the engine.”

powerTV: What has been your favorite hot rod project to-date and why? What makes it special?

Bret Voelkel: “I built a ’79 Ford Fairmont in 1988. It had a blown EFI 351W with an automatic and a 2:73 gear. I built that car in my head while I was driving for Auto Meter and MSD on the NHRA circuit that summer, and I put it all together in 58 days in the winter of ’88-’89. It was my daily transportation for three years. It ended up on the cover of a couple of magazines and was cheap, fast and reliable. I was working in an unheated, borrowed garage at the time. I made my own “radiant heat” system from two slabs of cardboard and an electric blanket to keep warm under the car.

I drove it from Indiana to Clearwater, Florida one winter and ran around that scene, racing all the 5.0 Mustangs out on the Gandy bridge. That was fun until I started winning too much. Then nobody wants to race! I finally sold the engine to a guy in Columbus, Ohio and sold the body to a local kid who promptly trashed it around 1993. That sale financed my first air suspension car, the Pro Street ’70 Mustang that I still have.”

powerTV: How did you end up starting RideTech, and how did you assemble your team of dedicated enthusiasts?

Bret Voelkel: “I left the NHRA circuit in 1989 and went to work for Blower Drive Service from 1990 to the end of 1994. At that point I had started dating my wife Sharon and was tired of traveling 300 days per year, so I went to work locally for a guy who owned an SK tool truck. I was also neck-deep in building my ’70 Mustang during that period. As the car got closer to being finished, the interest in the air suspension that I had created was increasing and my interest in the tool business was decreasing. We finished the Mustang and started Air Ride Technologies in April of 1996.”

At that point I had absolutely no knowledge of accounting, manufacturing, or any other business skills. I read a lot and talked to a lot of people. I was blessed with a lot of luck and a completely loving wife with a good job to support my hot rod habit. As with any business venture, there are at least 100 situations that could have sent me back to a real job. As far as the people, Jasper, Indiana is a small town – everyone knows everybody. The planets aligned several times when Greg Schneider, Craig Meyer, Steve McPherron, Rodney Mason, and Tony Bicknell landed on my doorstep. As for success, I think that as a group, we were just too dumb and ornery to realize we could fail.

The transition to the RideTech name last year has been in the works for a few years. As we have expanded into a few “non-air” products, the RideTech name seemed to be a more appropriate representation of our company. The fact that ridetech.com has been our website address since the beginning in 1996 was an added incentive to make the change.”

powerTV: Air ride suspension from OEM manufacturers is usually associated with big, softly-sprung luxury cars, and aftermarket systems had kind of a reputation for only being a show-car thing. How did you overcome that image, and develop systems that were performance-oriented?

Bret Voelkel: “There did seem to be the perception that air suspension was for vehicles that only cruised the parking lots. This came from the fact that these customers were the first group to adopt the technology. Over the last few years we have demonstrated that an air suspension has many tuning and performance benefits on the track as well. It is all a matter of how the components are compiled and tuned. Every engine has a crankshaft, pistons and cylinder heads. Proper component selection and tuning will determine if the engine is appropriate for a boulevard cruiser or a Top Fuel car.”

powerTV: What are the advantages of an air ride suspension, and who would benefit most from your suspension systems?

Bret Voelkel: “We have three distinct groups of customers: Customers who want a great ride quality, customers who want to raise and lower their car, and customers who want to improve their handling and cornering performance. There is always some crossover, but nearly everyone can be safely placed in one of those groups. The beauty of the air suspension is that we can successfully address all of these groups with only minor system tuning.”

powerTV: What can we expect from the next generation of air ride suspension systems?

Bret Voelkel: “We have been, and remain in constant development of refinements for our suspension systems. We have spent a biblical amount of time and money working with electronic leveling systems over the last 14 years, and there is still much to accomplish there. Control and adjustability are key to successfully optimizing a suspension system for peak performance, whatever your definition of performance happens to be.

Electronic shock valving, wireless ride height sensors, high capacity tankless air compressors, and improved bushing materials and design are all in active development right now. What the customer really wants is a suspension system that will completely eliminate any road irregularities, sit the car on the ground, raise it immediately to a safe highway ride height, make the car corner like a race car, and have it jump out of the box and magnetically attach itself to the vehicle. We are getting there!”

RideTech has recently branched out into bolt-in suspension parts like these tubular StrongArm control arms.

powerTV: There have been a lot of improvements in the way parts get designed, tested, and manufactured since you first got into the business. How has that technology changed the hot rodding market?

Bret Voelkel: “CNC machinery had made it possible for an individual to bring his ideas to reality in small enough quantities to be feasible, and the internet had made it possible for this same guy to successfully market and sell those ideas for money. On top of that, ever-improving electronics are making the customization and control of vehicles even easier for those who care to learn.”

powerTV: What hot rod trends do you like right now? Is there anything you hope makes a comeback?

Bret Voelkel: “One, I see more and more people doing work themselves. The quality of aftermarket parts and systems has allowed them this opportunity. Two, I see more “lifestyle” type race and car show events. People seem to be gravitating from the huge mega-shows to the more intimate gatherings of like minded people and cars. I think the internet forums have inspired this to a great extent. Three, the internet is allowing more efficient communication between the manufacturer and the customer. Not only can the customer learn what the manufacturer can do, the manufacturer can get immediate feedback from the customers. And finally, customers are much better informed and are more demanding than 10 years ago. They don’t settle for copies, inferior design or quality, or lazy customer service. This bodes well for the customer and the better manufacturers.”

powerTV: Look into your crystal ball – what do you think hot rodding will be like twenty years from now?

Bret Voelkel: “600 horsepower V4 quad turbo 75 mpg crate engines, constant velocity electronic transmissions, all wheel drive, wirelessly-controlled magnetic fluid suspension systems for vehicle and their occupants, airless tires, composite body and chassis components, and vehicles that will weigh 1500 pounds. As far as suspension systems, you will see systems that will transmit road surface data in real time via satellite to an infinitely adjustable damper unit that will anticipate road irregularities and eliminate them. The technology currently exists – it just needs to be integrated.”

powerTV: If you could only drive one car for the rest of your life, what would it be, and why?

Bret Voelkel: “I get asked this all the time! I currently have everything from a Boss 429 Mustang to a 2007 Z06 Corvette. In the winter, I drive a 1997 Tahoe that has been lowered 10 inches. In the summer I drive whatever is sitting closest to the garage door, usually the Z06 or my 1970 GSX. If I could only keep one, it would be the GSX. It has a 560hp 455 engine, a ZF 6 speed , 18-inch wheels, 14-inch Wilwood brakes, Cerullo seats, A/C, Sirius radio, and room for my family. I don’t know why – it’s just cool!”