Images: Jet-Hot Coatings

Have you ever wondered what process your parts go through when you send them to get coated at Jet-Hot Ceramic Coatings? Well, you don’t have to wonder any longer. Thanks to the coating company, you can actually get a pictorial tour of the coating process by visiting their website. And there are more steps than you might think.

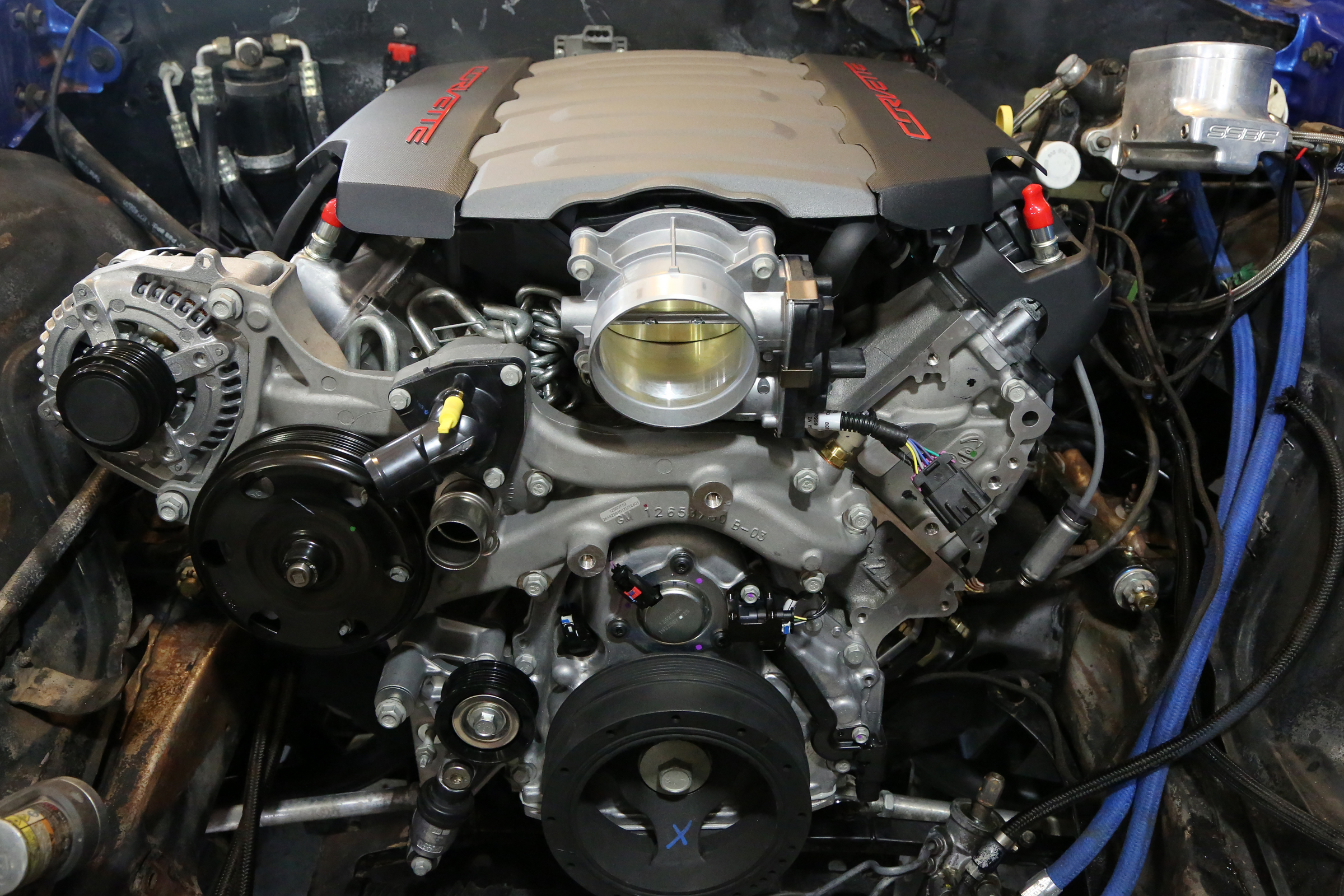

The process your automotive parts go through at Jet-Hot starts long before the actual coating takes place. When your parts arrive, they are inspected for any kind of damage and compatibility issues, photographed, documented, then issued a unique customer identification number that will travel with the part throughout the process.

The process your automotive parts go through at Jet-Hot starts long before the actual coating takes place. When your parts arrive, they are inspected for any kind of damage and compatibility issues, photographed, documented, then issued a unique customer identification number that will travel with the part throughout the process.

The parts are then treated to a bath to rid the components of any kind of contaminants or partials.

Aftermarket parts go through a degreasing process before moving on to the surface preparation stage. Here, parts are grit-blasted to remove things like corrosion, oxidation and rust.

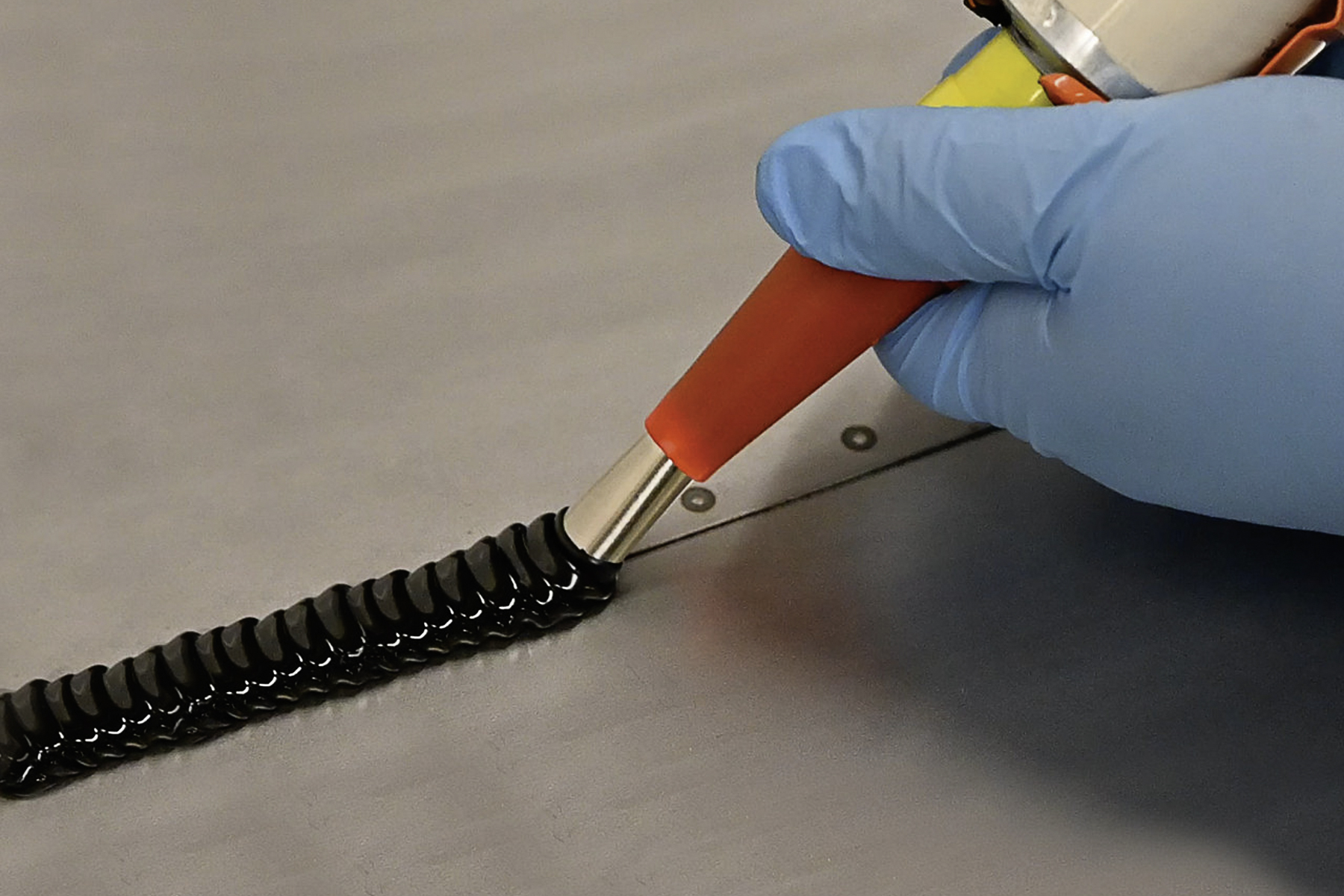

Step four in the nine-step process is actually when you see the physical coating take place. All components are coated inside and twice on the outside, with some components flow-coated on the inside depending on application. The coating is then cured in electronically-controlled ovens.

Step four in the nine-step process is actually when you see the physical coating take place. All components are coated inside and twice on the outside, with some components flow-coated on the inside depending on application. The coating is then cured in electronically-controlled ovens.

After the coating has cured, all parts are inspected for any kind of flaw that could have occurred in the coating process. Jet-Hot’s painstaking inspection means you get perfectly coated parts guaranteed.

Once everything checks out in the inspection, each part is polished in the polishing room. Jet-Hot uses a special set of vibrating machinery to achieve the polish you’ve grown to expect from the company. If you request a certain color top-coat, the finish is then lightly blasted before the color is applied. Colored parts then go through an extra curing process.

Before being packed up and sent back to where they came from, parts are compared against the initial photographs that were taken, the order form and the unique identification number given to the part when it arrived. Shiny parts are then hand polished.

All items end their journey by being packed up. Customers can pick up their coated parts at Jet-Hot or have them shipped to a specified destination. No matter the means of receiving them, each customer will find care information on their parts in the box.

All items end their journey by being packed up. Customers can pick up their coated parts at Jet-Hot or have them shipped to a specified destination. No matter the means of receiving them, each customer will find care information on their parts in the box.

Who knew that coating automotive parts took so many steps? While this looks like a lengthy process, Jet-Hot doesn’t seem to mind. After all, it’s the customers’ satisfaction that they’re aiming for and have accomplished time and time again with this practice. Check out the full Jet-Hot coating process gallery here.