You can never be too rich, too thin, or have too much horsepower on tap. While we’re perpetually broke to the point of ordering off the dollar menu at fast food restaurants, and as a result are having trouble getting into shape (unless that shape is a sphere), we’re never going to give up our pursuit of more ponies to the pavement.

There are a lot of different roads to follow that dream, but when it came time to take the next step with Project Y2k, our in-house 2000 Corvette, we wanted to find a way to break through that magical 400 rear-wheel horsepower mark without having to get any further into the wet part of the stock LS1 powerplant, or take out a HELOC to finance it. Affordable, reliable power is where we set our sights.

NX GM LS 3-Bolt Plate System Contents

- 78mm billet aluminum nitrous plate

- Jetting for 50, 100, 150, 200, 250, 300 and 350 horsepower at the wheels

- ProPower Lightning series nitrous solenoid

- 10 pound capacity nitrous bottle with billet aluminum Lightning 45 bottle valve

- 6AN feedline and braided stainless solenoid-to-plate lines

- All required electrical connectors and mounting hardware

Y2k’s previous upgrades boosted power to the tires to more than 370 horsepower – good for the daily commute, and well within the limits of what the stock LS1 internals can tolerate essentially forever. But for those moments when ‘only’ having more power on tap than an LS3-powered C6 just isn’t enough, a flip of the switch will bring Y2k the firepower necessary to hunt down and vanquish enemies like the Shelby GT500, and even surprise a few C6 Z06-with-bolt-ons guys should we engage in a little fratricide.

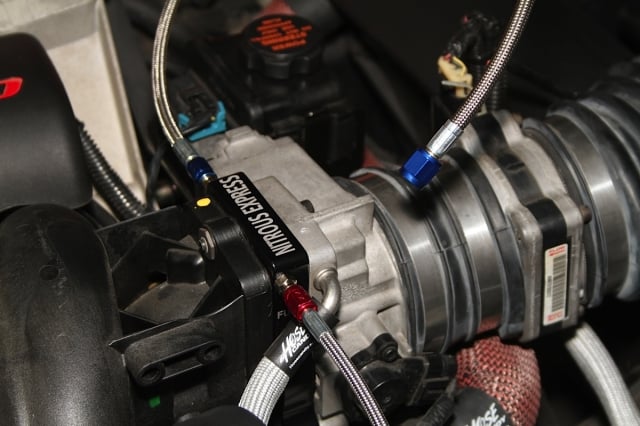

Why did we go with the NX plate system? As we have previously pointed out, Nitrous Express offers a lot of different options when it comes to adding horsepower to an LS powerplant. To achieve our desired 100-shot, we could have gone with a system that introduces nitrous oxide via an adapter plate in the MAF housing, a single nozzle in the intake tract ahead of the throttle body, or even a direct port system that placed a nozzle in every intake runner. But the plate system, which sandwiches a 78mm billet plate between the throttle body and intake manifold, offers an appealing combination of very easy installation, performance, and compact design (important considering the limited under-hood real estate on our C5 Corvette) making the choice easy.

Accessories like a blow-down tube and burst disc adapter, bottle pressure gauge, and electric heater will make our system even more useful.

Improving on Perfection

Adding a purge solenoid to our system will allow us to expel gaseous nitrous oxide before the system is activated, for more consistent performance.

We also decided to accessorize the basic 3-bolt kit with some very useful add-ons:

- NHRA Safety Blow-Off Fitting (PN 11709) – This adapter allows connection of a blow-down tube to the nitrous bottle, which directs the contents outside the car should the safety pressure burst disc activate, and it’s a requirement for drag racing when the bottle shares the passenger compartment with the driver.

- 12-Volt Bottle Heater (PN 15942) – Maintaining the proper temperature, and thus pressure, in the nitrous oxide tank makes for far more consistent performance and safer operation.

- Nitrous Purge System (PN 15600) – By placing a small nitrous solenoid close to the main one, gaseous nitrous oxide can be “purged” from the system before activation, preventing a momentary rich bog when the stage is activated. This is also useful for impressing the fans in the stands at the dragstrip…

- Maximizer 4 Progressive Controller (PN 15957) – A progressive controller allows the nitrous oxide and fuel to be brought in smoothly in response to inputs like engine RPM or vehicle speed, helps avoid wheelspin, and will do a lot to protect our Corvette’s driveline from sudden shock loads.

The Nuts and Bolts

Installation of any nitrous oxide system comes down to three basic parts; physical installation, plumbing, and wiring. Thanks to the simplicity of the NX system, the physical installation literally just takes a few minutes, with the most involved work being devoted to actually mounting the nitrous bottle.

Plumbing the system requires connecting the solenoids to the plate, installing the appropriate jets in the process, then providing fuel and nitrous connections from their respective sources. The electrical hookups for the basic 3-bolt plate system are very simple, and just require a few connections to put the master arming switch, wide-open throttle switch, and solenoids in series.

The heart of the system is this billet aluminum plate that has internal machined passages for fuel and nitrous, which mix and are atomized as they exit the four orifices seen here. The plate uses a factory-style reusable seal rather than a gasket to ensure there are no vacuum leaks in normal operation.

The nitrous and fuel jets, which are precisely calibrated metering orifices, are installed in place between the plate and the stainless steel AN lines that run to the solenoids. Always use a backup wrench on the plate fitting, and don’t crank down too hard – these connections take far less torque to properly seal than most people expect.

Physically mounting the plate just requires unbolting the throttle body and sandwiching it between the TB and the intake manifold. On our application, spacers for the power steering reservoir were required to allow clearance for the C5's throttle-by-wire module.

NX doesn’t know how to do anything in half-measures; this system utilizes their Lightning solenoids which feature lightweight billet aluminum bodies and carbon fiber ‘cans.’

Nitrous Express provided this gorgeous laser cut bracket to attach the solenoids to the cylinder head. You can see the smaller blue purge solenoid connected directly to the port on the main nitrous solenoid.

With the plate and solenoids in place, we turned our attention to the nitrous oxide bottle. We replaced the standard blow-down fitting with an adapter for the blowdown tube, and installed the pressure gauge before figuring out exactly where we wanted to mount the bottle. Nitrous Express includes stainless steel bottle brackets with the system, which we used to mount the bottle in the back of our Corvette. Once in place, we started the plumbing phase by running the braided stainless nitrous supply line out through the floor and under the car to the engine bay, where it was connected to the nitrous solenoid.

General Motors was nice enough to install a handy fuel supply point for our nitrous system right in the factory fuel rail, though they have to call it a ‘test port’ because of lawyers and stuff. Converting it to its true purpose just requires removal of the valve core, and attaching the AN fitting that supplies the fuel solenoid.

Physical mounting and plumbing complete, all that remained was wiring up the system. Because we’re using the Maximizer 4 progressive control, the electrical side was a little more involved than just the basic system, but there are enormous benefits to using the sophisticated electronic device. Keep an eye out for an upcoming article where we dive into how to use the Maximizer to, for lack of a better word, maximize the effectiveness of our nitrous system.

The fact that we were also adding a purge kit made for a few more plumbing and electrical connections, and the Maximizer 4 does require some additional wiring and programming steps, but someone going to install the basic-but-complete 3-bolt plate system is looking at an easy afternoon under the hood.

Lingenfelter Upgrades for Safety and Performance

We had previously installed a Lingenfelter Performance Engineering LNC-2000 timing control system on Project Y2k, both for the 2-step rev control that holds a desired RPM at the starting line, as well as its built-in ignition retard function. Now, with the NX nitrous system installed, we connected the LNC-2000’s input to the Max4’s trigger, and set the ignition control to automatically take 2 degrees of timing out whenever the system was running – an important consideration when running nitrous on any engine.

LPE also provided their Walbro C5 Corvette Intank Fuel Pump Module kit, which is a direct drop-in replacement for the stock pump, capable of supporting 600 horsepower. The new fuel pump gives us the peace-of-mind we need to know we aren’t going to run lean with the nitrous system activated, and it has a very reasonable retail price of just $199.95. While we were at it, we also replaced the stock fuel filter to make sure there weren’t any potential bottlenecks in the system.

The Lingenfelter pump is a direct replacement for the factory pump, and provides a lot of extra peace-of-mind when running nitrous or forced induction.

Testing Our Results

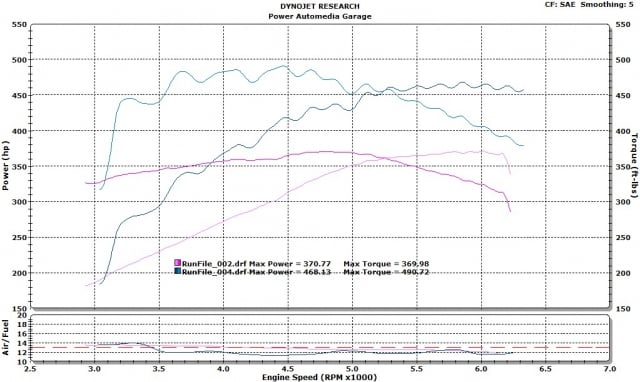

With the system installed, wired, and plumbed, all that was left was to put our Corvette on the Dynojet 224xLC chassis dyno and see if we got the improvement we were looking for. The initial dyno runs with the nitrous system inactive registered a baseline 370.7 horsepower and 369.9 pound-feet of torque.

The Maximizer 4 progressive controller does more than just offer precise control of power delivery – it also incorporates “window switch” functions and wide-open-throttle sensing. With the controller wired into the car’s stock throttle position sensor, and a connection made to the injector harness, a bit of programming let us set up the nitrous system to go active when the arming switch was thrown, the throttle was more than 80% open, and RPM was above 3,000. Those parameters guaranteed some additional protection against backfires, and to keep the engine from “loading up” at low RPM with a big hit of spray.

To test things before going for our desired horsepower numbers, we installed the recommended 50-shot jetting and set up the Max4 with a ramp-in that would take us from 50% duty cycle on the solenoids up to 100% between 3,000 and 3,500 RPM. With one “practice” pull proving that the system was working as designed, a quick swap to the 100 horse jets was all that was required before we were ready for the main event.

Nitrous purged and arming switch activated, we hit the throttle and were rewarded with a peak number of 468.1 horsepower and a huge 490.7 pound-feet of torque, precisely matching our expectations for the install – we picked up 97.4 horsepower and 120.8 pound-feet at the tires. Nitrous Express has always impressed us with “truth in numbers” when it comes to rating their jetting, and this system is no exception.

What’s Next

We’re very pleased with the way the Nitrous Express 3-Bolt LS Plate System met our goal of achieving more than 400 horsepower to the wheels, in terms of cost, time invested, and room for future growth. For the purposes of dyno testing, we barely scratched the surface of the Maximizer 4’s progressive features, but we’re looking forward to exploring all the power and flexibility the controller offers, and bringing that to you in a future article where we wring the car out on the dragstrip and even do a little bit of time attack closed course work to show how nitrous isn’t just for going in straight lines.

Now, we can start fine-tuning the Max4’s delivery curve to give us the best possible elapsed times without overwhelming the available traction. Thanks to the flexibility of the Max4, and the fact that it directly reads the throttle position sensor, we can also reprogram the controller to give us variable nitrous injection based on how hard we’re on the loud pedal – perfect for road racing, autocross, and open track events. Keep an eye out for future updates as we burn a few bottles of N2O!