If you want old-school looks with new-school performance, the pro-touring scene is the way to go. Learning this from the ever-growing popularity of the pro-touring movement, the massive amount of street-machines and performance-minded daily drivers we see on the roads and at events these days is certainly proof. We wanted to create our own well-rounded classic muscle car and purchased our second-hand 1964 Chevelle two door sports coupe as the perfect platform. However, no matter if it’s pro-touring, cruising or just killer looks you’re after, there is one thing that’s a must to get however much power you have to those rear tires and that’s a hardy transmission. Knowing we were going to beat the living snot out of ours on the street and the track, we contacted Gearstar Performance Transmission who set us up with a complete Performance Level 4 4L65E automatic transmission package. The choice for Project BluePrint couldn’t have been better.

Where We’ve Been

With BluePrint Engines helping us out with the power plant for our Chevelle, we knew we needed the same stellar quality for our transmission.

By now you’ve become acquainted with our BluePrint Chevelle through our continued updates on the car. Wanting a pro-touring beast, we’ve already showed you how we equipped the GM A-body with a complete RideTech suspension system for corner carving capabilities and SSBC brakes for plenty of stopping power.

We’ve also fitted the car with Billet Specialties’ Challenger wheels from their Street Smart Line and wrapped them in Continental rubber for an aggressive stance and even stickier gripping power.

Of course, upgrading our Chevelle’s setup is for one purpose and one purpose only- to drive the car to our heart’s content. To do this and make it a fierce competitor in autocross and open track competitions, we decided to fit our aptly named BluePrint Chevelle with a potent LS3 from BluePrint engines. This 427ci monster will push just over 600hp through the guts of the Chevelle, leaving one key ingredient to be discussed- the Gearstar transmission.

Since our Chevelle originally came with an automatic transmission and we wanted this car to be just as much cruiser as competitor, we decided to maintain an automatic gearbox.

Behind the Scenes – Gearstar Performance

Gearstar offers top notch quality with all their transmissions, whether you’re using it in a muscle car, pro-touring beast, restoration project, daily-driver or modern performance machine.

That’s because Gearstar’s owner Zack Farah wanted to do things a bit differently when he started the company in 2001- not focus on quantity like many other companies do, but rather focus on quality.

“When you order a transmission from Gearstar, you’re ordering a custom manufactured package built specifically for your car or truck,” Farah told us. “We have no units on the shelf. It [a transmission] has to be made for you.”

To create the perfect transmission for your vehicle, Gearstar builds everything specifically tailored to your application, including horsepower, rearend gear ratio and intended use. Matter of fact, once a custom Gearstar Performance transmission is ordered, the same qualified technician will follow the build from start to finish. Gearstar also customizes their transmission packages with converters stalled specifically for each customer vehicle and shift quality tuned specifically to customer taste. On top of that, Gearstar uses only the highest quality materials made in the USA. With each transmission built from start to finish by one of five master techs, you know you’re getting only the best drivetrain for your car.

With a name like Gearstar pushing all our Chevelle's power to the rear axles, you know we're going to have a potent street and track machine on our hands when we get done.

“When you call, you’re talking to a builder,” Farah told us. “There is no sales department.”

Gearstar transmissions can be found in all kinds of applications, from factory-correct restoration projects to blown 1,000hp LS off road vehicles. Since 2001, the company has built 5,869 transmissions, according to Farah, 3,861 of which have been built since 2005. That’s pretty good considering most of Gearstar’s business comes from repeat customers and word of mouth. There’s reason for that, too, considering Gearstar not only stands behind their products but also works toward a zero percent return rate policy. That means superior quality to begin with and a determination to correct and learn from anything that may not work as planned on an off occasion.

The Goods

Opening our shipment from Gearstar was like actually getting that pony you asked your parents for as a child- much anticipated and extremely exciting.

With top notch materials, a high quality standard and the know-how of five of the country’s best transmission experts behind their products, we knew we couldn’t go wrong with a Gearstar transmission.

To get the most out of our soon to be discussed BluePrint LSX crate engine, we were set up with Gearstar’s Level 4, 4L65E transmission package, complete with stall converter, flexplate, fan kit, HGM transmission controller and fluid. Yes, every Gearstar transmission is shipped filled 3/4 of the way full with transmission fluid and three extra quarts to top it off once installed.

“The best engine in the world is basically a paper weight unless you can put that power to the ground,” Farah told us. And the Gearstar 4L65E package will certainly do the trick for our BluePrint Chevelle.

The Level 4 4L65E transmission package is built to back engines making around 600hp and up to 600 ft-lbs of torque. For Project BluePrint, this package meant an 11-inch billet converter custom stalled for 2,600rpm, although a 10-inch and variety of stalls can be ordered from the company.

Project BluePrint is being built to dominate the track but also be a fairly well-mannered street car, so a 2,600 stall was the perfect way to go.

A Gearstar Performance Technician will build each transmisison from start to finish. It never changes hands until it's essentially crated up and ready for shipping. Left, a 5-pin Planetary (on bottom) vs. 4-pin Planetary (on top) along with a fully rollerized gear train, including Raybestos frictions and Kolene Steels shown on left. Center, a technician installs the more durable, 5-pin planetary system. Right, a stock drive assembly (on left) is compared to the much more durable Gearstar Heavy Duty Drive Assembly with Bearings

In addition to our custom stall converter, our Level 4 Gearstar transmission came put together with a master overhaul kit with Alto Hardened Kolene Steels, Raybestos Gen II Racing Frictions, heavy duty hardened sun shell, and high capacity upgraded pump assembly with new hardened pump rings. It also came complete with a 28 element input sprag, Transgo reprogramming shift kit with Shift Command, heavy duty five pinion front and rear planetary gear set with sun gear, super hold 4th servo and Corvette servo, wide carbon fiber 2-4 band, and hardened output shaft. The trany was topped off with new bushings, solenoids, Torrington bearings, valves and high rev spring kit.

Our Gearstar Level 4 4L65E is backed by a high capacity polished aluminum pan and Derale Performance transmission cooler with built in fan. Of course, we can't forget about the SFI flexplate that makes transmitting all our engine's power to the transmission possible.

Gearstar Performance's 4L65E - Level 4 transmission comes complete with torque converter and and even the transmission controller. However, Gearstar doesn't stop there. Each Level 4 transmission comes with a ton of key ingredients, which set this transmission apart from the rest. With horsepower ratings up to 650 with the ability to hold 600 ft.-lb, Gearstar was sure to add a hefty amount of internal strength. Gearstar adds Alto Hardened Kolene steels, Raybestos Gen II racing frictions, hardened pump rings, 10-vane pump rotor, complete torrington bearing kit, hardened sun shell and heavy duty expanded capacity input drum with reinforcing sleeve. To round out the package, a Corvette servo is added as well as wide, carbon-fiber 2-4 bands.

Tying It Together – The Install

Installing our Gearstar transmission in Project BluePrint was pretty straight forward from the start. With our master technicians on hand and the BluePrint engine not yet installed, we easily moved from pulling out our new transmission to mounting the new one up.

Although Gearstar Performace ships their transmissions with fluid in them and some extra quarts to top it off, we decided to use Royal Purple’s Max ATF automatic transmission fluid instead. So before any tying together started, we drained the transmission to make it a lot more manageable during install.

The first step to matting our Gearstar 4L65E to our new BluePrint engine was mounting the flexplate to the backside of the block. This was easily done by one of our tech, Tim Obetz, using a 15mm socket and air ratchet with the BluePrint engine still on the lift. We then torqued the bolts to 65 ft./lbs to finalize the install.

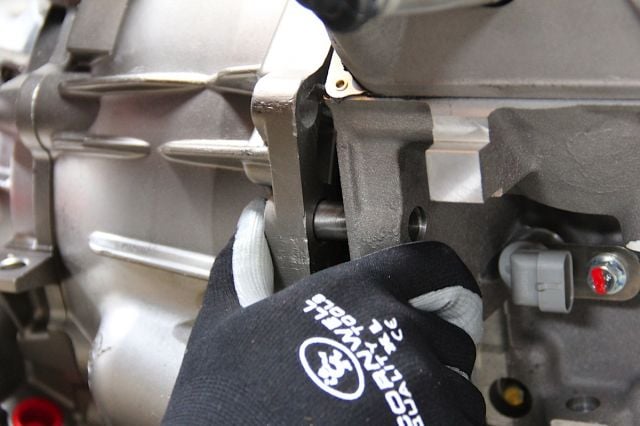

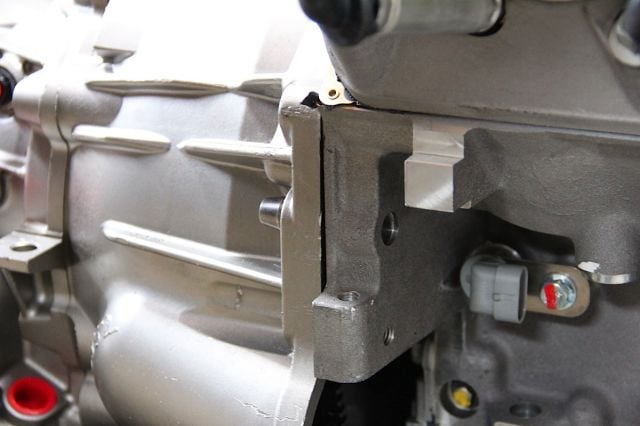

Once we fitted out flexplate to the engine, we lowered the block to make it flush with our transmission, which allowed us to easily slide the bellhousing in place against the engine before bolting it in place.

If you're doing a full engine and transmission swap like we are for Project BluePrint, it's much easier to attach the two main powertrain components together before installing them in your project. Not only does it save you time, it also saves you the hassle and frustration of working in tight spaces to get things like the bellhousing bolts in place.

Before our mock engine and transmission fitment could begin, we took some time to assure everything on the transmission was put together. This included the Energy Suspension transmission bushing. The Energy Suspension bushing bolts under the tail shaft of the transmission and then right to the transmission crossmember perch once the transmission is in the car.

If you're looking for the perfect LS conversion engine/transmission mounting kit, Muscle Rods has you covered. We installed the '64-72 A-body kit, which included a transmission crossmember, transmission mount, frame mounts, motor brackets, and of course a complete line of hardware for a simple installation. Installing the Energy Suspension bushing on our transmission was quite simple. Using a 17mm socket, the upgraded bushing was attached in minutes.

With the bushing on the transmission and our engine mounts secured to the block for fit and positioning purposes, we did a rough install of our powertrain components. This led us to find a few things we needed to address.

For good measure, we had test fit our engine and transmission combo to outline any potential fitment issues. For Project BluePrint, we encountered a fitment issue when it came to the transmission tunnel. Since the Gearstar transmission is much larger than anything that was offered in the Chevelle from the factory, the tunnel was just too small.

Plus, with our BluePrint engine sitting higher than what our project car came with originally, we faced even more clearance issues. So we decided to cut out the original transmission tunnel and build our own from scratch.

Plus, with our BluePrint engine sitting higher than what our project car came with originally, we faced even more clearance issues. So we decided to cut out the original transmission tunnel and build our own from scratch.

Once we relieved our GM A-body of its confining transmission tunnel, our engine and transmission slid easily in place. Of course when you’re talking about a combination this big, easy might be an understatement, but it sure beats the alternative.

Installing an engine and transmission combination can be a tedious process, but if you take your time and have some patience you can get the powertrain into place correctly without issue. Between doing a rough fitment to see how much needed to be modified with our transmission tunnel, test fitting to make sure we'd modified enough and putting the engine and transmission in for good, we got some practice with installing the engine and transmission combination in Project BluePrint.

Here you can see where we were running into issues with our Gearstar transmission fitting into our original transmission tunnel with the factory sheet metal removed. If you're going to run bigger components, you have to make the necessary modifications to make them work, but it's a small price to pay for the result you get in the long run.

Out with the old and in with the new- we created a new transmission tunnel to fit our engine and transmission combination by cutting and bending a piece of 16-gage sheet metal and welding it into place after precise measurements were taken. The tunnel was finished off on the underside of our Chevelle by tapping down the edges to make them flush with the undercarriage before the transmission was installed for good.

Once our transmission tunnel was complete, our next step was to install the motor mounts. Because these weren’t going to fit in the factory location with our BluePrint engine, we decided to weld them into place.

Sean Goude utilized a Lincoln 256 Power MIG for our welding duties for the transmission tunnel and motor mounts. It's critical to be patient and take your time to prevent warpage. Be aware of potential fires, especially when welding inside the vehicle. Our Power MIG is good for general sheet metal, general tasks, even tougher applications like 1/2-inch plate steel in necessary.

Another option would have been to drill new holes and bolt the engine mounts in, but due to their location and how much hassle it would’ve been to get to the bolts, we opted for the more practical option. This meant not only planning for the future but even more fun with the shop welding equipment.

Once the motor mounts were in place, we were able to slide our engine and transmission in for the final time and bolt everything together. It was also time for us to fill our Gearstar 4L65E with Royal Purple fluid.

Royal Purple’s Max ATF fluid is a full synthetic, high-performance fluid with a low co-efficient of friction and a high film strength that reduces heat and wear in your automatic transmission.

With the engine and transmission in their rightful location, the remainder of the install went quickly. Bolting up the engine mounts to our engine and the Energy Suspension bushing to our crossmember, positioned between the frame rails, was simple enough. The last thing we had to conquer was installing and programing the transmission controller.

Since our BluePrint powered Chevelle is far from an OEM application for our Gearstar transmission it requires a standalone controller, which we sourced got from Gearstar Performance. With our plug and play wiring in place, we bolted the controller unit to the passenger side firewall, connecting it to the handheld controller with a cable in the interior of the car.

Since our BluePrint powered Chevelle is far from an OEM application for our Gearstar transmission it requires a standalone controller, which we sourced got from Gearstar Performance. With our plug and play wiring in place, we bolted the controller unit to the passenger side firewall, connecting it to the handheld controller with a cable in the interior of the car.

With everything mounted and plugged in, we were ready to program our transmission controller for our Chevelle's best performance.

Once plugged in, we followed the online comprehensive instruction manual to complete our initial controller setup. By doing so, we were able to program our controller step by step with things like shift points and throttle position. Although we didn’t need it, the online manual also had instructions for troubleshooting, making it very easy for to follow and tackle any issues you may run into if you’re doing a similar install.

With our transmission controller programed and all the plumbing for our setup complete, we were ready to roll with our Chevelle. Of course, we’ll get more into the engine setup and dyno results when we take you through the BluePrint engine install in the near future. Keep an eye out for that update and more soon!

As with any upgrade to the factory drivetrain, protecting each one internally is critical. After our install was complete, we made sure to top off our freshly minted Gearstar Performance Level 4 transmission with 6 quarts of Royal Purple Max ATF fluid. Max ATF is a synthetic, high-performance, automatic transmission fluid. According to Royal Purple, its low co-efficient of friction and high film strength help to dramatically reduce heat and wear. Additionally, Max ATF is more oxidation stable than other transmission fluids for longer fluid life. Max ATF significantly reduces heat to extend the life of your transmission. Automatic transmissions generate a great deal of heat and depend upon the transmission fluid for cooling and protection. Initially, we began adding fluid at 4 1/2 quarts and started adding more as needed. Keep in mind, we were not only filling the transmission but the lines including the transmission cooler.

The Road Test

While we don’t have a ton of miles on our brand new drivetrain, our first experience with the new Gearstar Performacne 4L65-E transmission has only been driven short distances. Thus far, we’ve easily racked up the miles. What’s more, with ambient air temperatures floating in the triple digits, the transmission cooler and fan have done their job with flying colors. With the new install, we can cruise effortlessly at 75 mph with a low running rpm. Around town cruising and freeway jaunts are done with easy and since the rpm is lower, we can actually carry on a conversation. The transmission is super-smooth during cruising, however, once throttle is applied, the increased load with stiffen up shifts; just like it should. What’s more, we get instant downshifting whenever we got throttle happy.

As of right now, we can’t wait to get some additional miles under our belt. We really want to get this ‘Velle out on the autocross and open track events in our area to really flog this new combination. If you’re still slushing around in a three-speed with no overdrive, get on track and upgrade. You won’t regret it!