Perceptive owners of C5 and later Corvettes may notice a distinct assembly difference between vintage Corvettes and their late-model cars. Starting with the 1997 production year, Corvette’s body panels started using fasteners to hold the body panels together. Prior to that, body panels were held together by bonding strips and a bonding agent. Even the C4 Corvettes were still a hybrid of fasteners and the tried-and-true art of bonding bodies together.

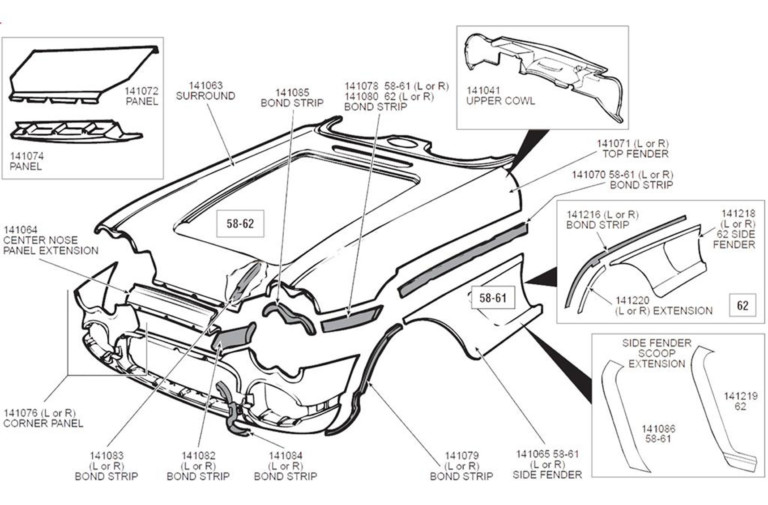

Bonding strips are those slender strips of fiberglass used to hold body panels together and to the car's birdcage. These illustrations from Corvette Central show the number of bonding strips used on a typical solid-axle Corvette body.

When Corvette was fledgling thought in the minds of its creators, the task of joining together the various body panels was handed over to an army of slim pieces of material called bonding strips. They would make assembling the Corvette body possible by holding panels together, while also fastening those body panels to the metal cage that surrounded the passenger compartment. We asked Tim Ames at J&M Corvettes about these strips and he shared some info and a bunch of images from J&M’s Facebook page.

Building Bonded

Bonding strips allowed workers to assemble the fiberglass bodies quickly and easily, using a bonding agent and strips of fiberglass material to bridge between the numerous panels. The assembly plants had body jigs set up in various stages to assemble the body panels throughout the process.

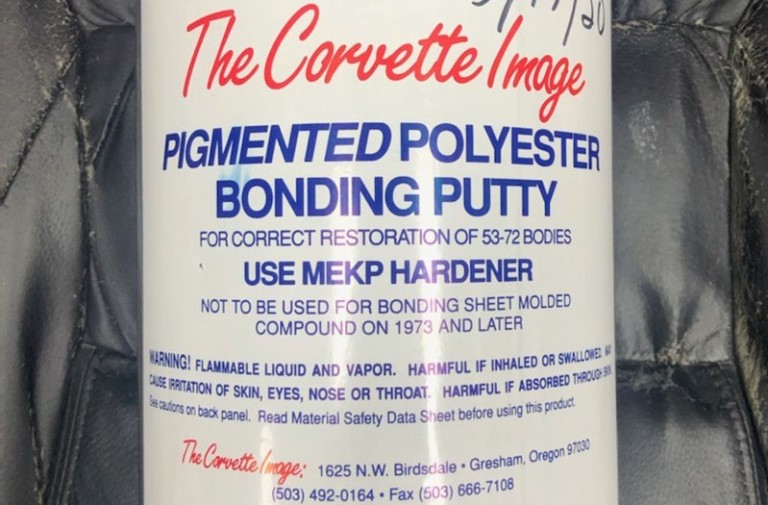

This early GM photo shows how many panels were joined together with bonding strips to make a midyear Corvette’s body.

Working with bonding strips can make repairs to a Corvette simpler — or harrowing — depending on your frame of mind. If you are a Corvette owner that winces at the thought of your Corvette going into the shop for any type of work, you won’t want to be anywhere near the body man if he needs to do panel replacement.

Since there are no fasteners and all of the panels on C1 through C3 (and some on C4) Corvettes are bonded together, the only way to remove a body panel is to mechanically separate that bond. This task is usually the job for tools such as hammers, chisels, and slender, pointy objects.

Much like watching a doctor wield a scalpel, separating bonding strips can be a rather violent view. A hammer and several thin, prying devices usually do the trick. The remaining areas are then dressed for the application of the new panels.

It goes without saying that once a panel is removed from the car, it does not get re-applied — typically. We’re sure you can imagine the extensive damage done by the removal process. Tim has been restoring Corvettes for decades, and we asked him whether or not reusing panels is possible.

“Most people think it is a myth that body panels can be removed and reinstalled without damage,” he says. “It takes a skilled person to remove panels without damaging them, but we do it a lot. I’m not calling myself skilled, but it has taken years to perfect the technique. Some cars are trickier than others. I treat each car differently — more patient and gentle — if I am saving a panel instead of replacing one because of damage. The most important thing is to know exactly where all the bonding strips are for each panel.”

This C3 Corvette had its complete upper surround removed. You can see how the inner fenders tie into the fenders and upper surround. Photo: CorvetteForum.com

But, if you’re removing a panel, it’s usually because there is already damage elsewhere. Replacement panels are available and installation parts range from the individual bonding strips themselves, to complete frontend assemblies. Body panels are available to round out the entire vehicle.

If the old panels are removed, typically they are replaced with new panels due to the extent of damage from mechanically removing them. Thankfully, all the necessary panels are available in the aftermarket. Photo: J&M Corvettes

Bonding strips not only adhere the panels together, but they also mate the entire fiberglass shell to the metal cage surrounding the passenger compartment. The “bird cage’s’ metal skeleton was designed to tie the body panels together and to give the body strength. It also allows for securing items like windows and hinges.

The metal "birdcage" ties all of the body panels together and gives the body its strength. Bonding strips are riveted to the steel frame and then adhesive is used to secure the body to those bonding strips. Photo: J&M Corvettes

The metal construction of the birdcage prompted GM to design a way to bond the body to the cage. Instead of bonding the body directly to the cage, GM used rivets to hold the bonding strips to the metal surface of the cage, and then bond the body to the bonding strips using adhesive. The presence of the metal structure did give the body added strength, but it is also the reason many enthusiasts had to deal with bonding strips since their Corvettes have left the factory.

At the plant, front and rear body sections were assembled and then installed onto the car's birdcage and floor tub.

Many folks wrongfully think that Corvettes don’t rust. In fact, they’re just as susceptible as any other car. — maybe more so. Over the years, water works its way between the body panels and the metal cage through small cracks or faulty weatherstripping. At that point, the forces of nature take their toll and rust begins to rot away our prized Corvettes from the inside out.

This birdcage has been severely damaged by rust. You can see the marks where the bonding strips once resided. Photo: J&M Corvettes

Many Corvettes have needed rust repair to the metal cages. In some severe cases, entire sections of the cage needed replacing. While the body panels looked fine, the cage was non-existent, a casualty of years of water intrusion. At that point, the body needs to be removed and the cage rebuilt. Since the old panels typically incur damage during the removal process, this is the time many enthusiasts replace them with new ones, and the bonding cycle continues.

Seeking A Bond

Bonding strips are typically easy to spot, thanks to them being located in areas that are accessible from under the car. The bonding adhesive used to hold the body together is a different color, and if the body is stripped of its painted surface, the lines of different-colored adhesive are a sure giveaway of body seams.

Use of bonding strips started with 1953 Corvettes and carried through until C4 production ceased. Bonding seams are obvious on a stripped body because the adhesive is darker in color than the surrounding fiberglass. Photo: J&M Corvettes

There is an array of bonding strips used to hold the Corvette’s body panels together. Thankfully, they are available through companies such as Lee Bumb Composites, Eckler’s, Mid-America Motorworks, Corvette Central and Zip Corvette.

As we mentioned, there are also complete, one-piece frontends available that greatly simplify replacing a damaged frontend. But, if you’re going to have the car judged, you’ll want to make sure that all the factory-style bonding strips are included so you don’t get a point deduction.

If you’re building your Corvette as a fun-mobile and never intend to have it judged, then bonding strips may be the furthest thing from your mind. However, if there’s a judging sheet in your Corvette’s future, it’ll be one thing judges will look for.

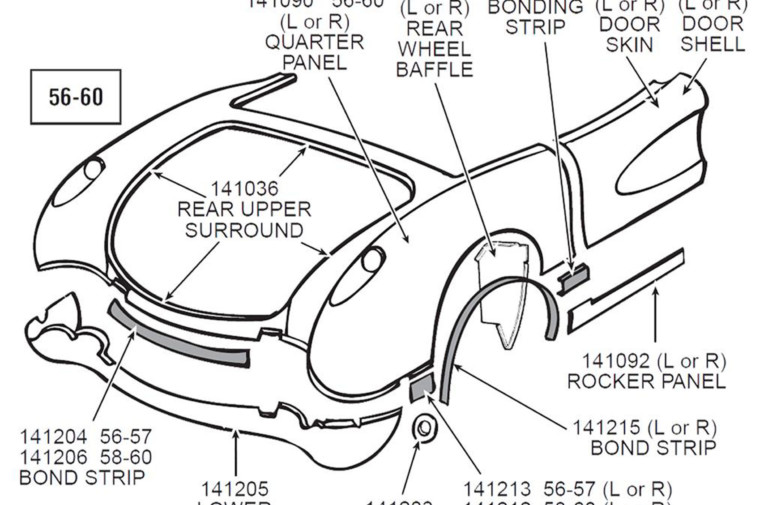

The assembly plant used an activated polyester resin as a bonding agent. The Corvette Image offers this Pigmented Polyester Bonding Putty that is used by many shops today to bond Corvettes together.

While many will pine for the ease of use and reusable nature of modern fasteners, the presence of bonding strips is one of the many things that make Corvettes special. Just like the fiberglass body is a characteristically-Corvette trait, those little strips of fiberglass have a mystique all their own.

Once you know a little bit about why GM used them and how to effectively work with them, they become just another thing that shows how outside-the-box Chevrolet engineers were envisioning when they created the car we all know as Corvette.