With the break behind them, the teams of the Horsepower Wars $10K Drag Shootout are headed into the home stretch of the 10-day build-off, and while there’s plenty of anticipation to hear the cars fire up and admire the fruits of their labor, the builders must first endure the tension that comes with a looming deadline at the close of those 10 days. For one team, the latter half of the build has been relatively stress-free, but for their peers, it’s been a race against the clock to overcome the trials and tribulations that come with building a racecar — particularly one in this kind of abbreviated timeframe.

Team Bigun is the only squad that isn't building an LS, instead going with a torque-monster in the form of a big-block Chevrolet on nitrous.

With parts arriving from Summit Racing, Team Bigun is toiling away on its 505 cubic-inch big-block Chevrolet; the team’s designated engine builder, Pete Harrell, has been applying his wizardry to the aluminum cylinder heads, spending hours on end, day after day porting them to extract every last horsepower out of the nitrous oxide-assisted mill. Utilizing as direct-port NOS nitrous system paired with a 1,050 cfm Holley Dominator carburetor, Bigun believes it has the tool to dispose off its three turbo LS-powered foes. But parts delays — combined with receiving the wrong set of heads, their transmission debacle earlier in the build, and the curve-ball that was the Granada wagon — has ratcheted up the stress level for the reigning champions.

Enemies Everywhere has approached their build with the largest of the three LS engines, a stock 6.0-liter truck engine, and paired it with an LS3 (also the only team to use such). The Australians have sourced a number of parts with high-pedigree and horsepower capability, including a custom, high-lift COMP camshaft. With goals of running upwards of 8,500 RPM, they should make ample power with their 80mm turbo. Like the other teams, engine builder Robbie Abbott has invested untold hours massaging the LS3 heads to improve airflow.

The Dream Team, for its part, is still reeling from some of its earlier internal conflicts and is working diligently to catch up to its competitors and get on the dyno before the final bell. The team is using a 5.3-liter LS with a combination of factory and aftermarket rotating assembly and valvetrain components to build a stout machine. An 80mm Precision turbo will provide the boost. While Team Begun and Enemies Everywhere haver their engines in the car and are now focused on other items on the checklist, the Dream Team is just getting their mill dropped into the SN95 Mustang.

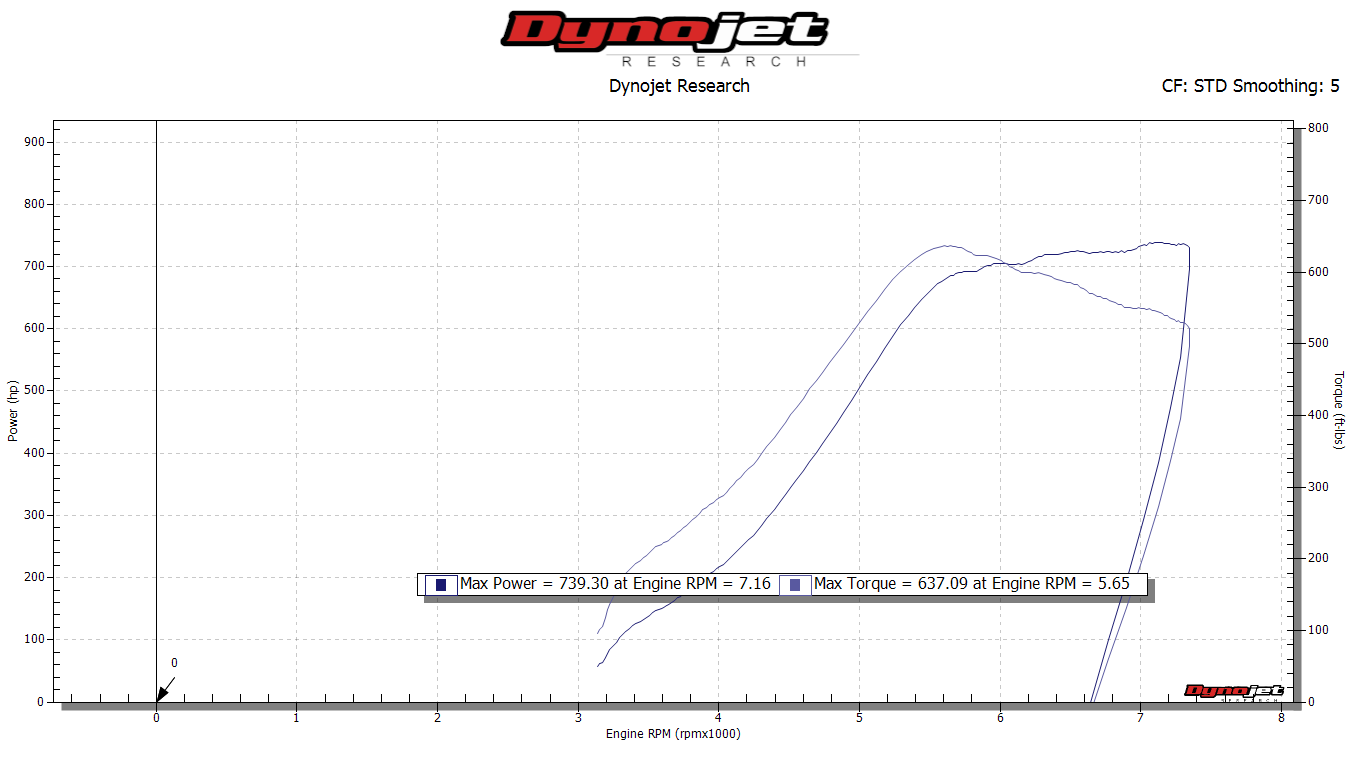

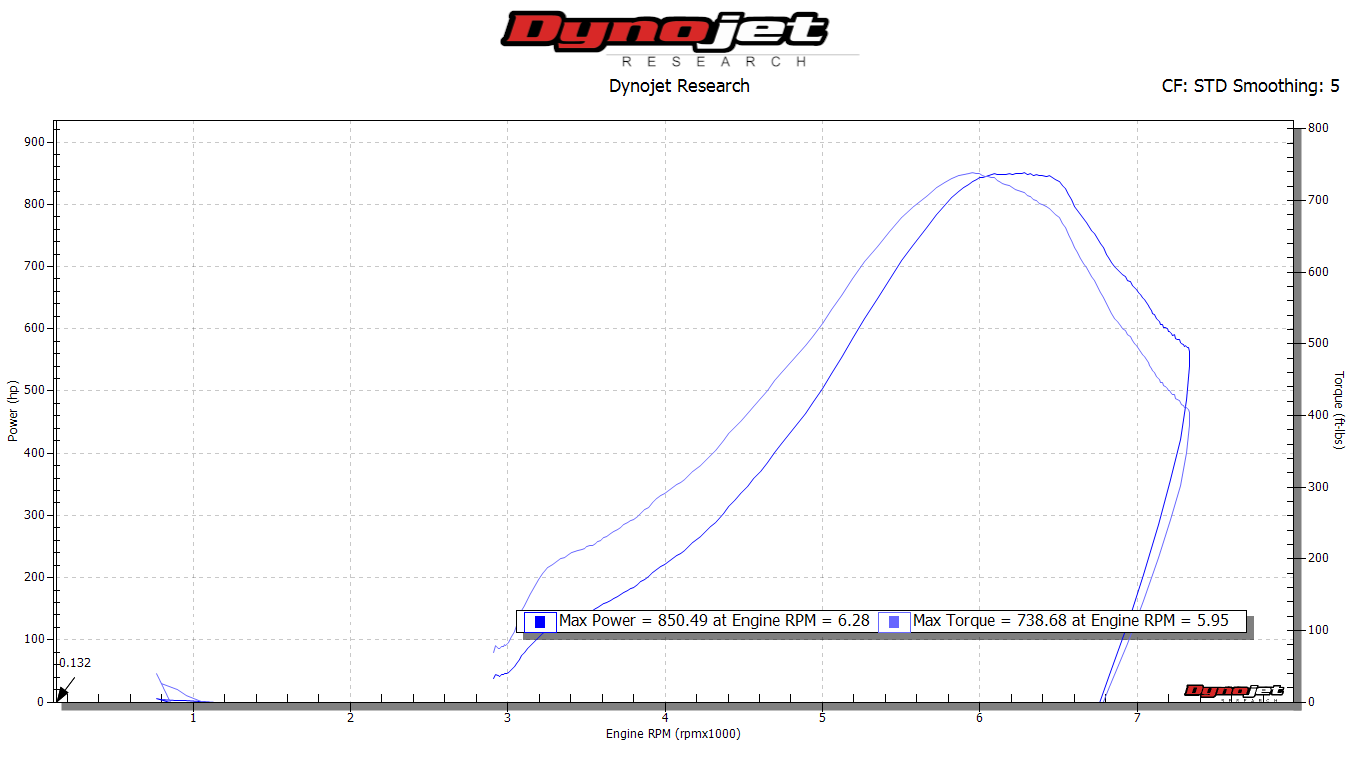

Midwest Mayhem was the first team to hit the dyno, cranking out over 700 horsepower after some adjustments.

And then, there’s Team Midwest Mayhem. This gang of street racers and no-prep racers with a background perfectly suited to this competition, came with a plan and executed nearly to perfection. The only hiccup, they might suggest, would be their less-than-ideal selection of the Oldsmobile Cutlass, but even that hasn’t closed their progress.

Chassis work largely complete and the engines assembled, the teams are turning their attention to the drivetrain, electronics, and plumbing.

Midwest Mayhem cranked out 739 horsepower on one of their initial pulls before tweaking on the tune, increasing the boost, and topping out at 850 horsepower.

Much of that swift progress, of course, is owed to their decision to utilize a largely bone-stock 4.8-liter LS engine fresh out of the junkyard. Team leader Joe Hunt has pored over the factory cylinder heads, using his experience with other junkyard LS mills to coax all the power he can out of the 290 cubic-inches at his disposal. Midwest Mayhem, like the other LS-powered teams, has chosen an 80mm turbocharger and positioned it in the passenger-side headlight to feed it fresh air. This squad was not only the first to strip their car and complete chassis work, but had its engine in the car and fire in the pipes a full day ahead of everyone else…and did so seemingly without breaking a sweat. On the first dyno run, the Junkyard Dog cranked out 550 horsepower on a mere 8-pounds of boost and 7,400 RPM. Further pulls netted more than 700 horsepower.

Mahle has provided each of the team’s with sets of PowerPak pistons for their specific engine combinations.

With the exception of Midwest Mayhem, which kept the stock slugs in the engine, each of the teams has sourced custom Mahle Motorsports pistons for their engines. These pistons, Mahle’s PowerPak line, are high-volume shelf-stock pistons made of 4032 aluminum alloy for tight cylinder-to-wall clearances and improved temperature stability. Enemies Everywhere has gone with an LS3 1.304 x 4.030 10.5cc dish piston; Bigun a set of BBC slugs kept secret by Harrell; and the Dream Team a set of LS3 dome pistons.

To go along with the pistons, Total Seal hooked the teams up with ring sets for their engines.

The pistons are paired with a set of Total Seal’s industry-renowned rings to ensure not only longevity, but peak combustion with the turbocharged and nitrous oxide power adders applying amplified explosions in the chambers. Despite the stock pistons, Midwest Mayhem has used Total Seal’s plasma-moly, 96.000mm bore, 1.5mm, 1.5mm, 3.0mm thickness ringset; Enemies Everywhere a 4.030-inch bore set; Bigun 4.350-inch bore; and the Dream Team 3.800-inch bore.

Each of the teams is utilizing Victor-Reinz head, oil pan, exhaust, and other gaskets.

For gaskets, Victor Reinz has supplied the teams with its multi-layer steel pieces, likewise ensuring longevity and, paired with ARP bolts, the ability to push more boost and nitrous through the low-buck engines. The teams are using Victor Reinzs’ MLS head gaskets, steel exhaust manifold, intake manifold, engine oil cooler, and valve cover gaskets, along with oil pump O-rings.

From assembly to fire-up, engine to rear end, Lucas Oil has the teams covered with lubricants.

Like the gaskets, Lucas Oil has supplied the teams with a full compliment of its products, from those designed for the engine assembly process to the fluids tasked with maintaining well-oiled machines on the track. As seen throughout the buildups, the teams are using Lucas’ semi-synthetic assembly lube, intended to pre-lube bearings, cams, lifters, and valvetrain components and prevent dry starts. The teams will then use 10-W40 weight oil blended specifically for racing engines. High-temperature and high-pressure semi-synthetic Automatic Transmission Fluid likewise ensures smooth operation in the Turbo 400 transmissions, and racing-specific L9 Gear Oil does the same for the pinion and axles inside the rear end housing.

The cars are powered by lightweight, 13.5 lb. Dyna-Batt batteries, contained in Moroso battery boxes. For safety, Moroso also supplied master kill switches that the team's are required to have on the vehicle's tail.

Providing the spark for the engines and the various electronics systems in the cars is a lightweight 12-bolt, 16 amp battery from Dyna-Batt. These batteries weight a mere 13.5-pounds, with the cranking power of wet cell batteries three times its size. Built for high performance and racing purposes, the dry cell battery has been tested to crank engines up to 15:1 compression. No one here is going that high on compression, so this battery will give them air to spare.

The battery is housed inside Moroso’s Sealed Battery Box (PN 74051), which is designed for relocating batteries in vehicles with or without a firewall and is fully approved by NHRA and IHRA. The box holds a Series 21, 24, 26, 34, 42, 54, 55, 56, 61, 62, 63, 85, 86, or 96R battery with top-post or side-post terminals. Also from Moroso and for the purpose of added safety is a heavy-duty Battery Disconnect Switch (PN 74101), intended for street cars and race cars with alternators or multiple battery applications. The kit features an easy-to-install quick disconnect switch, and a quick twist of the non-slip handle shuts off all electrical current to the vehicle’s systems — valuable in the event of a crash, fire, or other incident.

These black Fragola AN hoses and fittings work as good as they look...and they look good.

Lastly, fuel and oil systems are the lifeblood of any engine, and those systems are only as good as the components, and Fragola Performance Systems has hooked the teams up with its lineup of black -AN braided hoses and fittings. Parts from -4 through -12 are utilized in the cars for the fuel, oil, and transmission plumbing, ensuring both simple installation and leak-free, long-lasting operation. Oh, and they look pretty good under the hood, too.

Stay tuned, as next week the teams will race against the clock to get their machines on the dyno and ready for the big race!

A special thanks to all of the sponsors that help make the second season of $10K Drag Shootout possible, including Summit Racing, COMP Cams, Mickey Thompson Performance Tires & Wheels, TCI, K&N Filters, MAHLE Motorsports, Dyna-Batt, Weld Racing, Corsa Performance, Fragola, Holley, DiabloSport, NOS, E3 Spark Plugs, Total Seal, Moser Engineering, BMR Suspension, Miller Electric, Aerospace Components, Victor Reinz, Moroso, US Gear, Hawk Performance, Lucas Oil, PRW Industries, Weld Racing, VP Racing, ProCharger, and ARP.