Feeding the ever-increasing cubic inch trends in racing engines puts a demand on the delivery of air and fuel passing through the cylinder head. In the big-block Chevy arena of racing engines, Air Flow Research (AFR) has expanded their product line with an entirely new head to handle the flow demands of 540 cubic-inches and more.

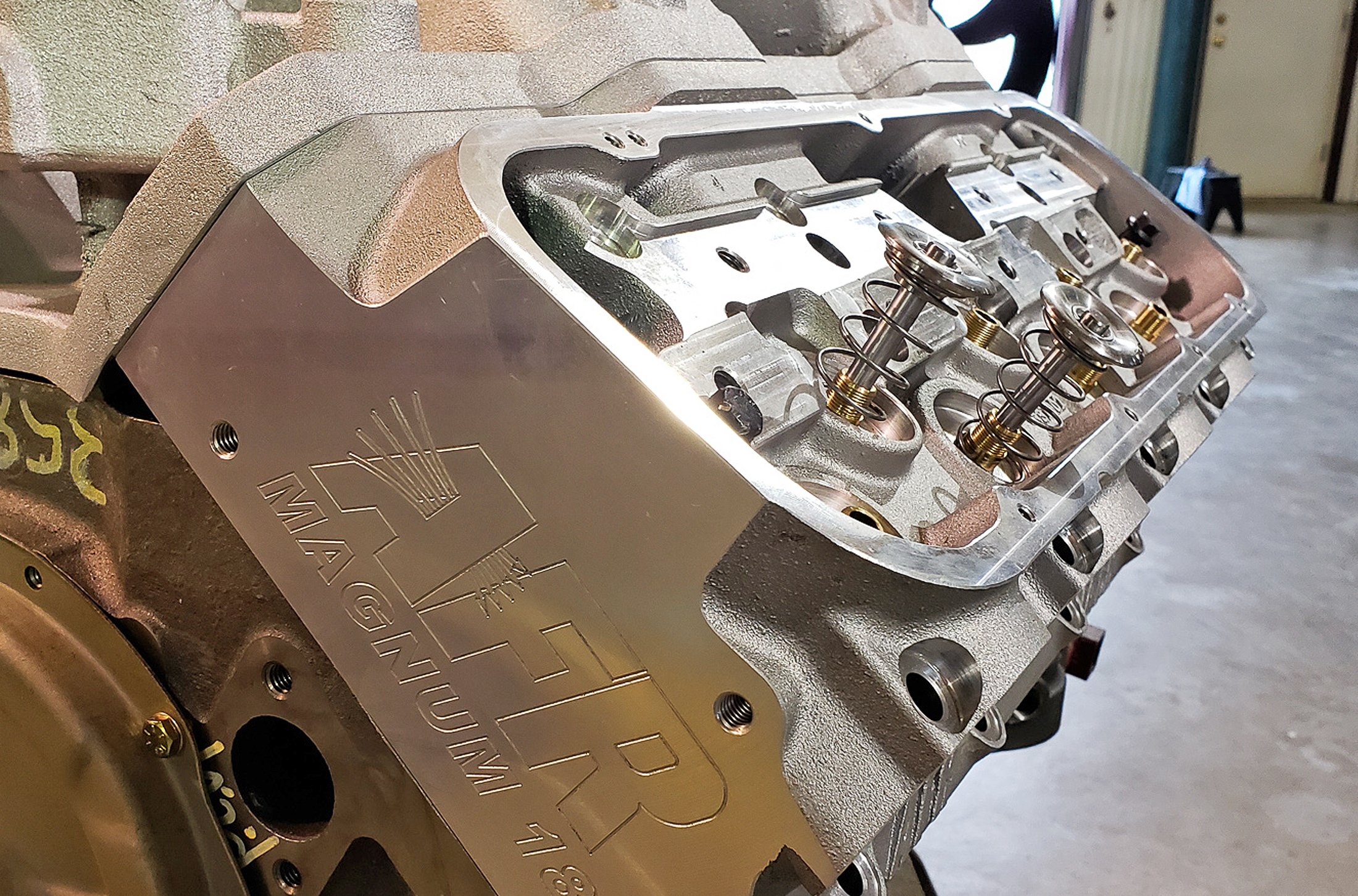

The new AFR Magnum line of 18-degree cylinder head is a design that cures many shortcomings of the Chevrolet factory 26-degree and even the performance 24-degree heads.

“Many performance head designs flatten this valve angle to 24-degrees,” says Chris Sperling, Director of Engineering and Technology at AFR, who took the alteration even further to 18 degrees. ”This angle change fundamentally improves airflow, horsepower, and torque. There are a lot of modifications in the chamber design on top of the rolled valve angle. Even the exhaust valve angle is rolled just a little bit more.”

The very first set of AFR Magnum 18-degree heads and intake were introduced to one of the toughest tests for racing components. The combination of putting out over 3,000 horsepower on the track while living on the highway was put to the test during Drag Week in Dennis Taylor's twin-turbocharged '72 Nova.

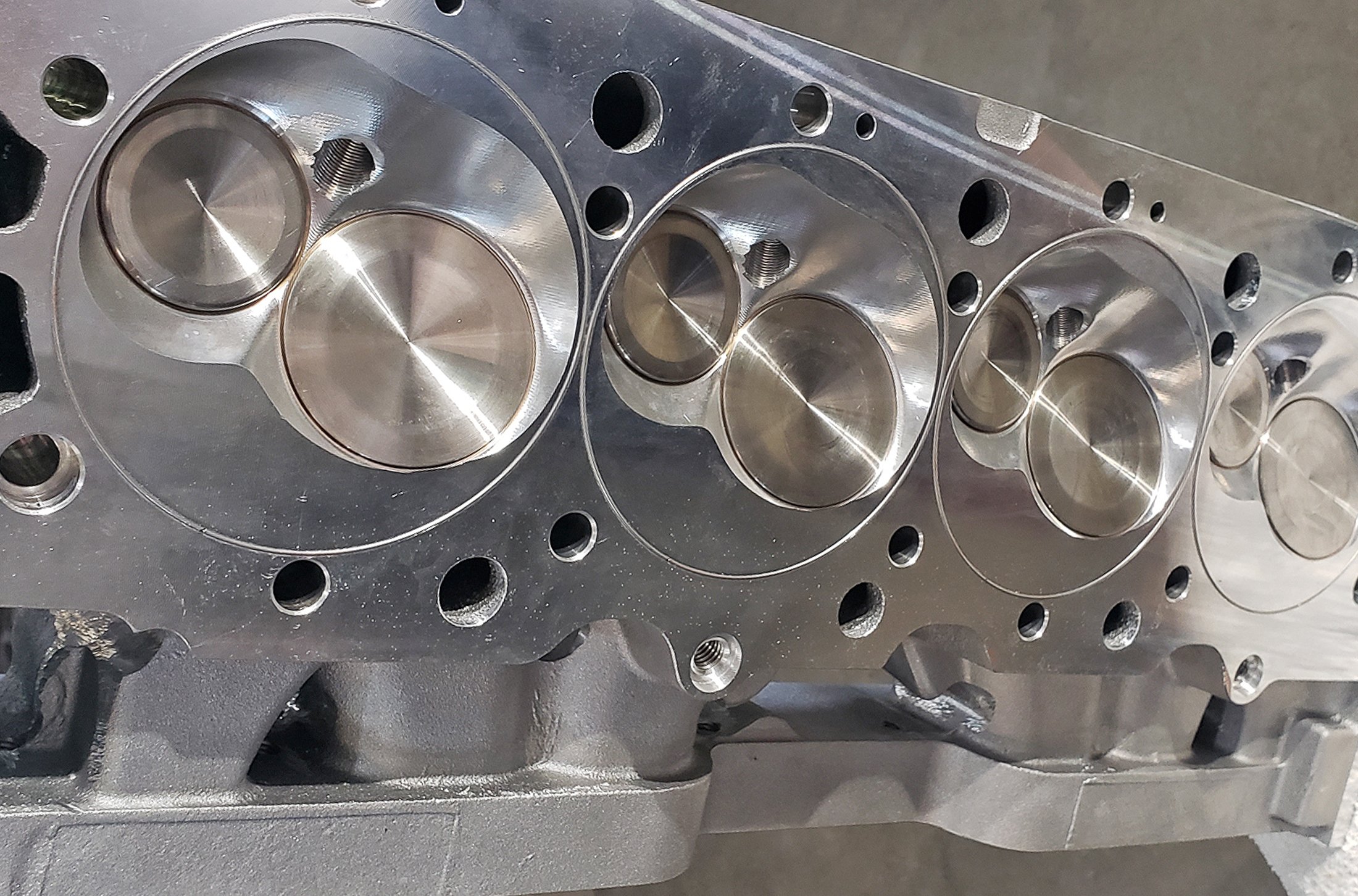

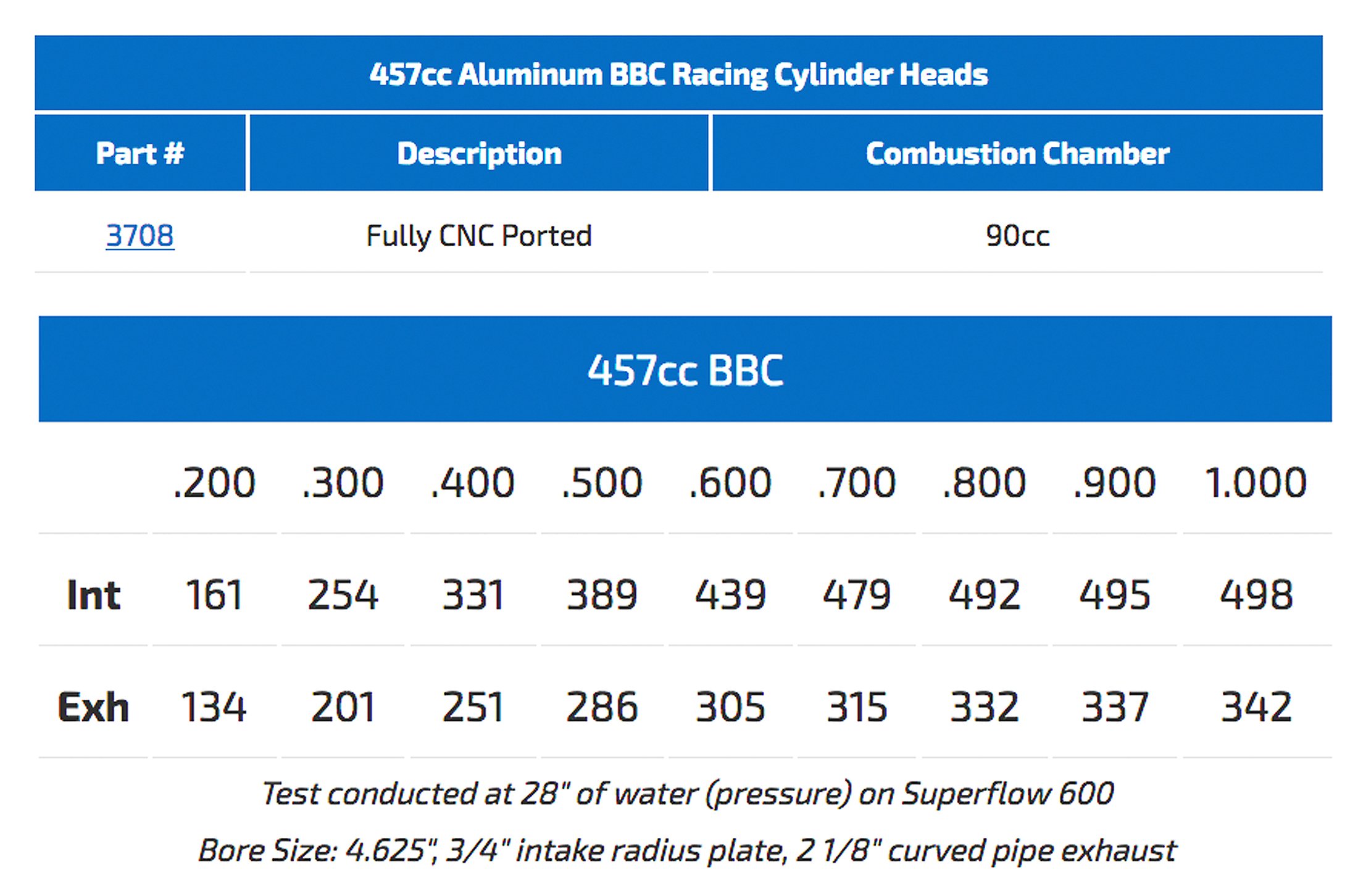

On the intake side, the AFR Magnum 18 intake ports are raised 1/2-inch and flow an impressive 498 cfm at 1.000-inch valve lift with a 457cc intake port volume. On the exhaust side, the port is raised .450-inch with a port volume of 143cc and flows 342 cfm at the same 1.000-inch valve lift.

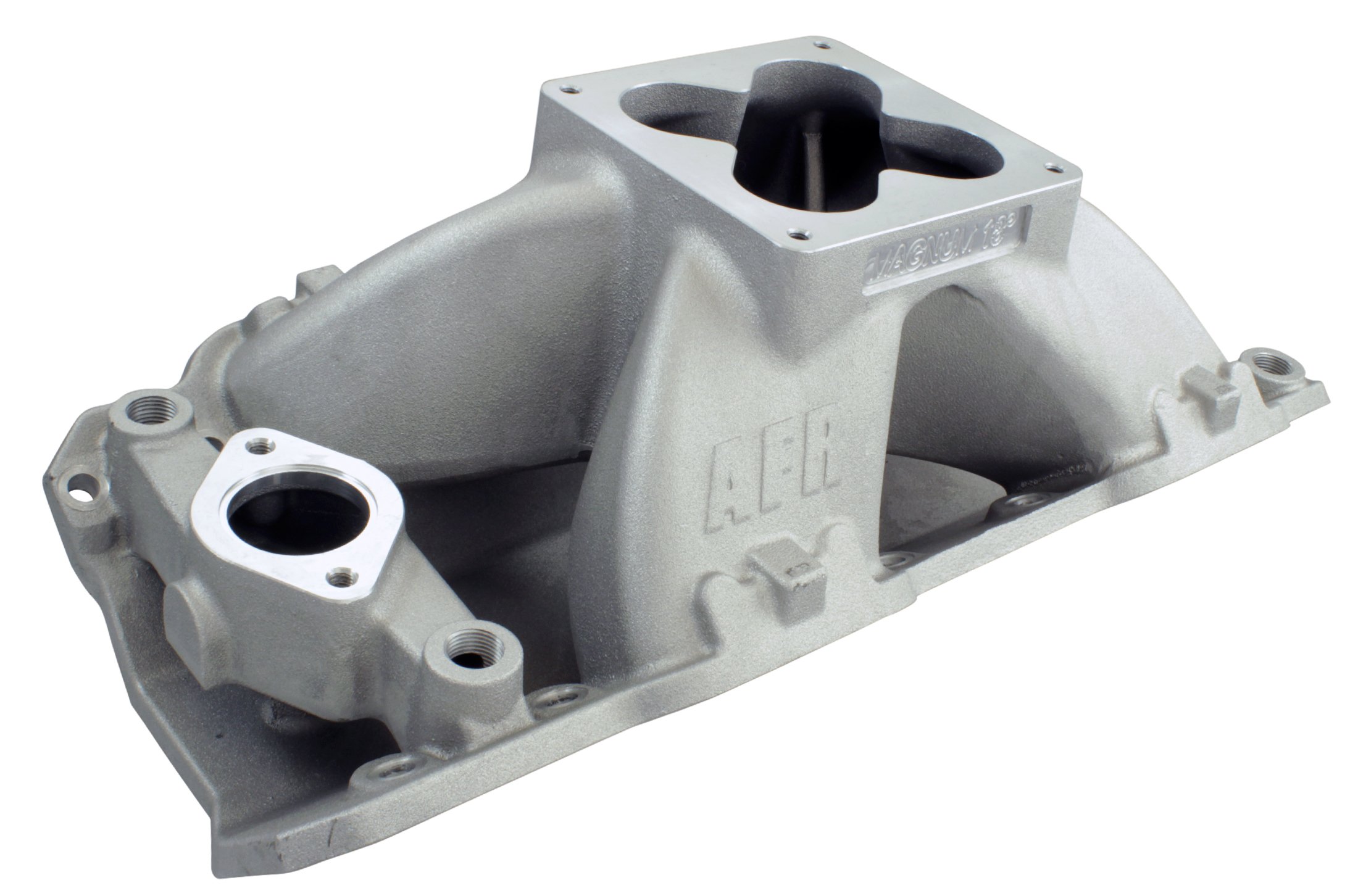

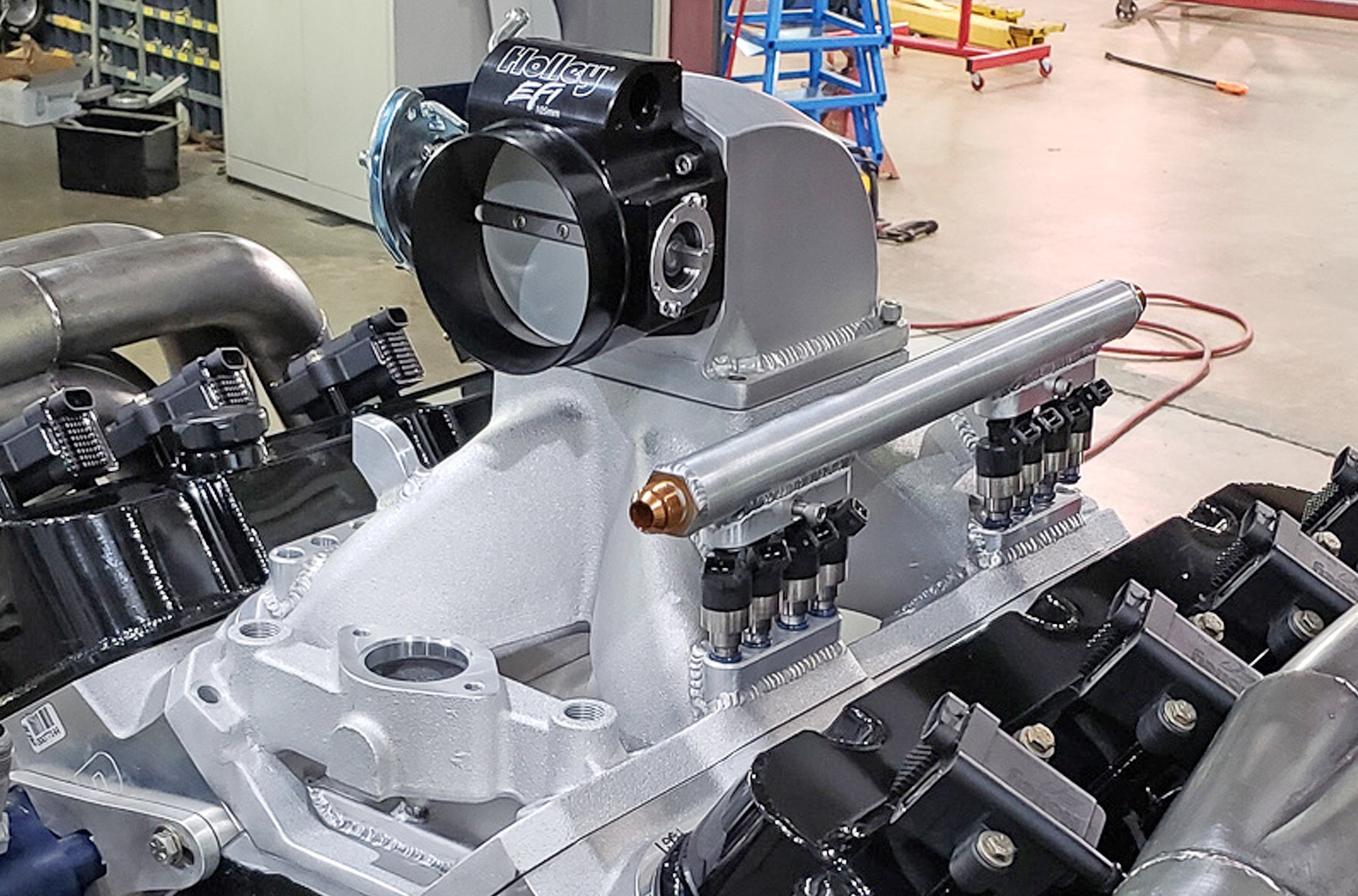

With the relocated height of the intake ports on the Magnum 18 heads comes a matched AFR Magnum series intake manifold for proper port alignment. They are available for 10.200- and 9.800-inch Chevrolet block deck height with a single 4500 carburetor cloverleaf flange. AFR intakes are designed to run “as cast” and offer plenty of material for generous porting options.

Though the exhaust port is raised .450-inch, the bolt pattern and port shape match a standard big-block Chevrolet exhaust. The only critical factor is to ensure that your headers can tolerate being located slightly higher in relationship to chassis and body clearances.

The Magnum 18 combustion chamber is a more efficient heart-shaped design which is very critical to overall flow design of the intake and exhaust port flow. In that same overall flow design by AFR, the intake runner is raised .500-inch while the exhaust port is raised .450-inch compared to a stock head design.

Some AFR history explains the motivation to create this new cylinder head and intake combination.

“In 1970, Ken Sperling took ownership of Air Flow Research known for their innovative porting techniques used throughout motorsports,” Tim Torrecarion, Director of Marketing and Sales explains. “When we lost Ken, many of our new products gravitated towards more street/strip applications. This new head and intake design is a big step at getting AFR back towards our roots into higher end racing hardware.”

"We highly modified the Magnum 18 intake manifold for the twin Holley injectors at each intake port. There is a lot of meat to work with in both the heads and intake," Taylor notes.

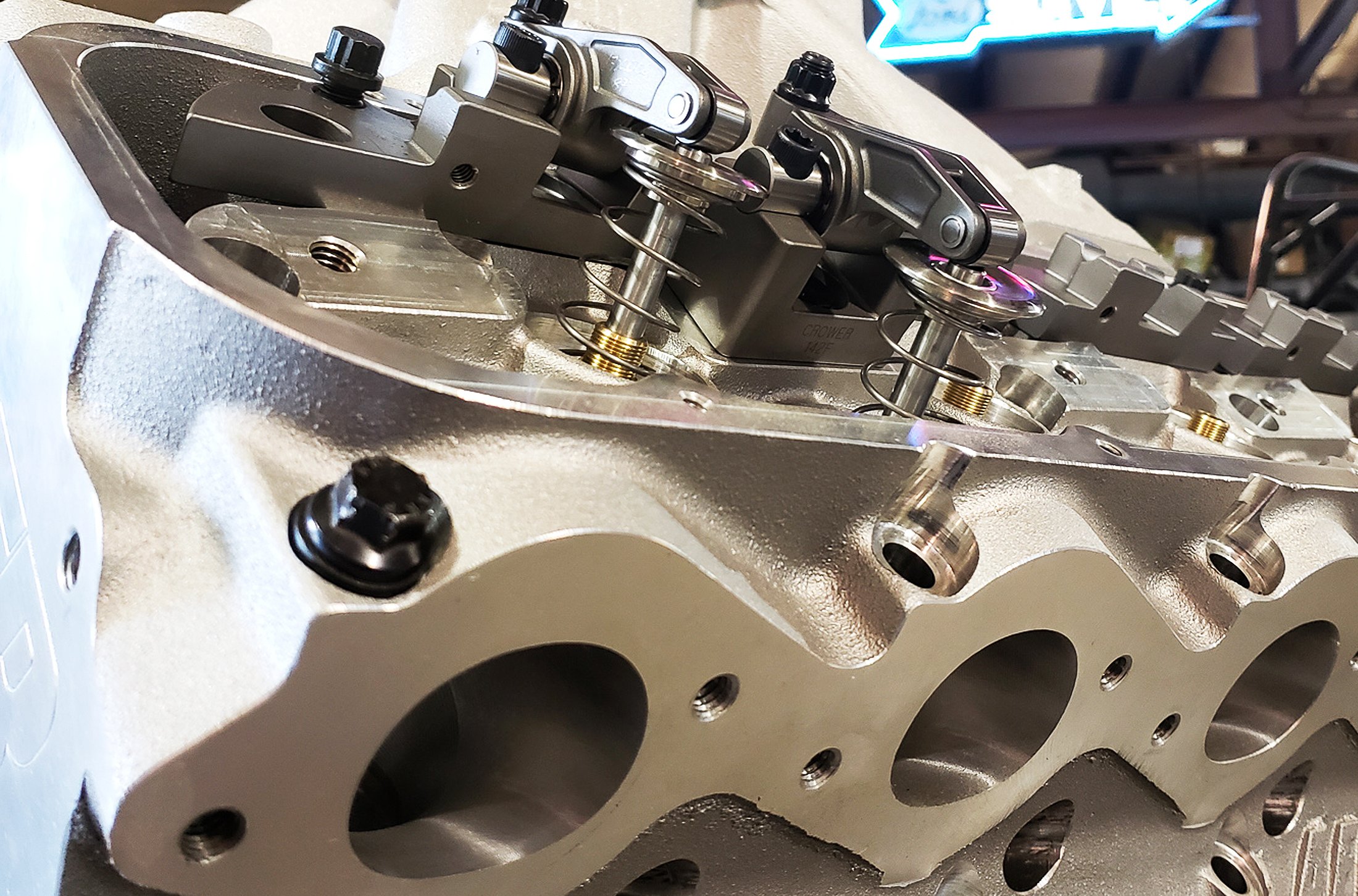

The heads come standard with stainless steel 2.400-inch intake valves and 1.800-inch exhaust valves. Both valves feature 11/32-inch valve stems, bronze valve guides, PAC Racing triple valvesprings, and 10-degree titanium spring retainers.

A wide range of options and upgrades for the Magnum 18 cylinder head are available including titanium valves and copper beryllium intake and exhaust valve seats. The heads are offered in bare form without valvetrain components, as well.

In the real world of drag racing, the heads have already seen action in one of the most extreme applications that hardcore racing engines can endure: Hot Rod Drag Week.

The new head design flows an impressive 498 cfm intake and 342 cfm exhaust at 1.000-inch valve lift. Many notice the impressive numbers at this maximum valve lift but the savvy engine guy also notes the high flow rates at lower lift points across the chart.

Debbie and Dennis Taylor compete in the Super Street Big Block Power Adder (SS/BBPA) class in their 1972 Nova. The new powerplant for this year was a turbocharged 509 cubic-inch tall deck big-block Chevy. Taylor applied the new Magnum 18 heads and intake to an engine that not only needs to make massive power at the track but also must live for miles over the highway.

“We more or less built this new engine combination around these heads,” Dennis says. “We’re shooting for 3,000 streetable horsepower. I didn’t have a chance to put the engine on the dyno before Drag Week, but the horsepower and torque numbers are going to be there just because we made our performance goals at the event so effortlessly.”

The port flow on these heads is outstanding. With the same turbos, and the same engine management system and less cubic inches than our previous engine, we went right from 8.20s in this 3,700-pound car to 7.80s the first time out. – Dennis Taylor

The AFR spec sheet notes some impressive numbers when it comes to the amount of material designed into the heads for strength and room to modify. Their proven A356 aluminum head material used on all AFR heads is machined at AFR with large 1.750-inch spring pockets and offer a full 3/4-inch deck thickness.

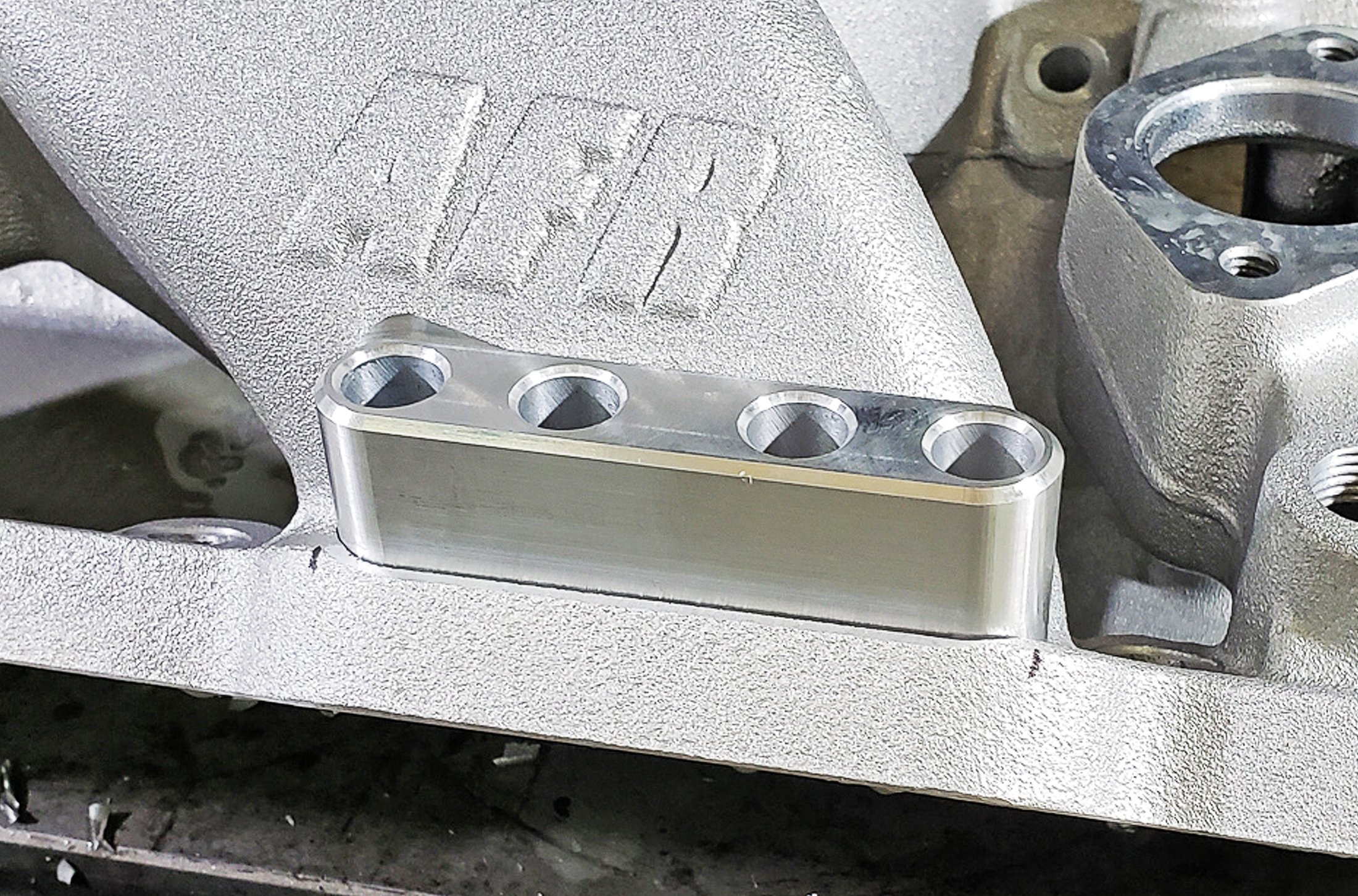

“We knew we were going to push the head material when we modified them for 1/2-inch diameter pushrods,” Taylor described. “On the Magnum 18 intake manifold, we also highly modified the carb flange and plenum area for our 90-degree turbo inlet and added provisions for 16 Holley Performance 160 lb/hr fuel injectors. The material is there on the AFR stuff do all of the modifications we wanted to do.”

The tall deck 540 built in Taylor's own shop uses a Crower 4.00-inch crankshaft, 6.800-inch Crower rods, and custom Bill Miller Engineering pistons with 1.094-inch wrist pins. An interesting addition to the blocks billet steel main caps, Taylor designed and machined a billet aluminum girdle and oil pan rails that secure the front four main caps with a cross-bolt design similar to a Chrysler Hemi block.

Air Flow Research partnered with a number of notable engine builders when testing the new Magnum 18 head design.

“They’re putting the new heads and intakes through the wringer right now,” Torrecarion tells us. “We basically said here is a new casting. See if you can break it [laughs]. The response has been very favorable.”

With a fresh cylinder head design comes related components that require many custom specifications. For example, the valve angles may not clear some rocker arms or readily fit some aftermarket stud girdles. The AFR spec sheet lists their own AFR stud mount rockers or recommends 1.8-inch shaft-mount rocker arms from T&D Machine, Jesel, and Crower Cams.

As cylinder head designs begin to vary from OEM dimensions, related components like push rods, rocker arms and domed pistons need to follow the specs defined by the head manufacturer. AFR offers a detailed compatibility sheet listing proper components.

With some domed racing pistons, modification may be necessary for clearance due to the Magnum head’s more efficient heart-shaped combustion chamber design. Some newer piston dome profiles for an 18-degree style head will clear, however. Since this new Taylor 540-inch engine is a completely new build, new pistons were machined to match the new head chambers.

“I can tell you that the research and development team here at AFR has spent thousands of hours to get the intake and exhaust flow numbers we have achieved,” Torrecarion says. “Taking a fine-toothed comb over the design and locations of the Magnum 18 ports, we were able to surpass what was currently available in the market. Otherwise, it wouldn’t have been worth our effort to create these heads.”

AFR does strongly cite that when modifying the chamber area, material should be removed from the piston and not the cylinder head. The Magnum 18 head combustion chamber shapes are very critical to flow. Altering the cylinder head can adversely affect flow and power characteristics.

“We also looked deeply into all good designs that came from the history of our entire product line,” Chris Sperling explains. “Through the years, we’ve learned what works and have incorporated those strong points into all of our cylinder heads and manifolds. Any new products or casting updates that we do will assure that we have appropriate material thicknesses in the right places.”

That first set of Magnum 18 heads used on the Taylor’s Nova ultimately laid down a 7.86 elapsed time at 182 mph. — those performances were achieved going across the scales every day at around 3,860 pounds.

“The car has sub-7.50s in it,” Taylor tells. “We were just very cautious going straight into Drag Week without any testing. Our 60-foot times equate to an excellent prediction of future elapsed time numbers. These heads and intake are the biggest variables we updated that resulted in improving our performance.”

These new heads offer an example of that AFR calls a “clean sheet design.” Critical points like a minimum of .200-inch of the port to water jacket thickness is a must. This material thickness eliminates hot spots within the heads that can cause harmful detonation.

With the clean sheet design, the AFR design team shapes and optimizes port design first. Then they secondarily design their castings around those optimized port and chamber shapes. These design theories provide significant benefits to the head in regard to its overall strength and integrity.