If you are looking to drop some elapsed time at the drag strip and get a few mph out of it as well, there are few options to go with. One option is the use of Nitrous Oxide (N2O), and Nitrous Oxide Systems, better known as NOS, makes adding this powerful gas to your muscle car so easy it can be done in as little as an afternoon. We decided that while big horsepower numbers are good, good old-fashioned track testing is the real-world test for performance. We decided to outfit our Trail Blazer SS with a “100 shot” of N2O to see how much time we could lose in the eighth-mile as well how much trap speed we could pick up along the way.

To compliment our NOS kit we selected a few other goodies to make sure we were getting the most out of our system. First, to make sure that the nitrous bottle would be at the proper temperature and pressure we installed a NOS Pressure On Demand (POD) kit that included a bottle warmer and a remote opener. Second was a Progressive Nitrous Controller, also from NOS, that is able to use a signal from the Throttle Position Sensor to activate two window switches giving us the ability to really dial in our nitrous kit. Lets take a look at everything we’re talking about here before we get into installing the kit.

NOS LS2 Plate Kit – Part Number 05169NOS

• LS2 Plate Assembly

• 10 pound bottle with racer safety

• N2O Super Pro Shot Solenoid

• Cheater Fuel Solenoid

• Bottle Mounting Brackets

• Basic Wire Pack that includes switches, wiring, and connectors

• All necessary hardware to install kit

NOS POD System – Part Number 14182NOS

• POD Main Controller

• LCD Display

• Bottle Opener

• Bottle Heater

NOS Progressive Nitrous Controller – Part Number 15974NOS

• Progressive Controller

• Hand Programmer/Display

Nitrous Facts and Fiction

Before we get into the installation and testing, let it be clear that the NOS Plate Kit for the GM LS2 engine is a complete system and does not require the other two components. We felt that to get the most from our nitrous system, we wanted the ability to monitor and control it as precisely as possible – hence the POD and progressive controller. Nitrous bottle pressure is greatly affected by heat and because the temperature surrounding the bottle can change rapidly, we wanted to be right on top of things and make sure that we were able to adapt to any changes from track to track or even run to run. There’s a lot of half-truth floating around about how temperature and pressure effect nitrous performance, so to set the story straight, we spoke to Bill Tichenor of Holley Performance Products (parent company of NOS), to learn the five things you NEED to know about nitrous before you even think about pushing the little red button.

Number One: You can add nitrous to a stock engine

Many people think that if you are going to add nitrous to your car, upgrading things such as pistons is a requirement. “You can add nitrous to a stock engine with no problem,” says Tichenor, “as long as you add the right amount.” He says that up to a 75 horsepower shot can be safely added to a V6 and stock V8 engines can handle up to a 100 – 150 shot with no problem.

Number Two: Nitrous isn’t flammable

No matter what you may have learned from the fine documentary film, The Fast and The Furious, nitrous oxide itself isn’t flammable. “If you were to light a match, then crack open a nitrous bottle pointed right at it, all it would do is blow the match out and probably freeze the hand of the guy holding the match,” says Tichenor, “Nitrous Oxide is an accelerant. It introduces more oxygen to the cylinders, allowing more fuel to be put in as well.” While this means that a nitrous bottle won’t explode in a mushroom cloud like Hollywood would have you believe, it’s still stored under considerable pressure and should be treated with respect and caution, like any compressed gas.

Number Three: You don’t have to swap your fuel system

As long as your stock fuel pump is up to spec and you aren’t putting in more than a 250-shot of nitrous, your stock fuel system is usually adequate for supplying enough fuel for your engine on the spray.

Number Four: Nitrous can be used on more than just naturally-aspirated gas engines

While nitrous is best-known as a power-adder for naturally-aspirated gasoline powerplants, it makes a great addition to diesel or alcohol-burning engines too. “Nitrous is a great compliment to boosted engines as well,” explained Tichenor. “It takes care of turbo-lag, or just as an overall performance enhancer.”

Number Five: If you’re retuning a car that has nitrous, make sure the tune is a nitrous tune.

Many aftermarket tuning companies use strategies that advance timing to make more power. Under a nitrous run, this can lead to possible detonation. Check with your tune provider before installing the tune and make sure it’s a nitrous-friendly one.

The Heart Of The Operation: The Plate Kit

The NOS LS2 plate kit is an easy install, even if you’re new to nitrous. Here’s what we needed to install our kit.

• Drill

• Socket Set

• Wire Crimpier/Cutters

• AN Wrench

It all starts with the bottle. Picking the right place to mount your bottle is not the first step by chance. In fact ,according to Tichenor, the entire kit working correctly relies on mounting the bottle appropriately.

Tichenor told us that NOS kits perform best when the bottle is at 950 PSI and the maximum working pressure is 1100 PSI. To keep us under the 1100 PSI limit, NOS recommends mounting your bottle away from heat sources like the engine and exhaust as well as other heat sources such as direct sunlight through windows. You might think keeping the bottle near the driver would be a good idea so they could open and close the valve as needed. “You can mount the bottle next to the driver,” said Tichenor, “but the safest place is in the rear of the car.” That way if there is ever a problem with the system and nitrous leaks out, it won’t be near our driver. We went ahead and decided to mount it in the cargo area of our TBSS.

Another point to consider is bottle orientation, and to understand why you have to take a closer look at what makes up an NOS bottle. Inside, below the valve is what is known as a siphon tube. This tube is connected to the valve and runs all the way down to the bottom of the bottle at roughly a 45° angle, away from the label on the front of the bottle. This ensures that every last drop of the liquid nitrous oxide is being drawn into the system, if you mount it correctly.

According to NOS, the most efficient mounting option is known as the ‘lay-down position’ which is described as having the valve closest to the front of the vehicle, the label up, and the bottle sitting at a 45° angle. Our kit included a bracket to mount the bottle in just such a way. We started by using the supplied bottle brackets as a template to see where we would have to drill to mount it. After fastening it to the trunk floor, we drilled a hole in the bottom of the trunk to run our nitrous and blow-down tube out of the passenger compartment. Having a blow-down tube is an important safety feature. Should our bottle be overfilled or overheated to the point where pressure is too high, all NOS bottles come with a blow-off safety valve that releases all the contents of the bottle to prevent the bottle itself from failing. While we hope that this will never happen, should it occur we don’t want the contents of the bottle filling the passenger compartment. The blow-down tube connects to that valve, directing it out of the vehicle. NHRA regulations require a blow-down tube on any nitrous bottle that shares the passenger compartment with the driver, and since our Trail Blazer doesn’t have a separate trunk with a bulkhead isolating it from the main cabin, our track’s tech inspector will be looking for it.

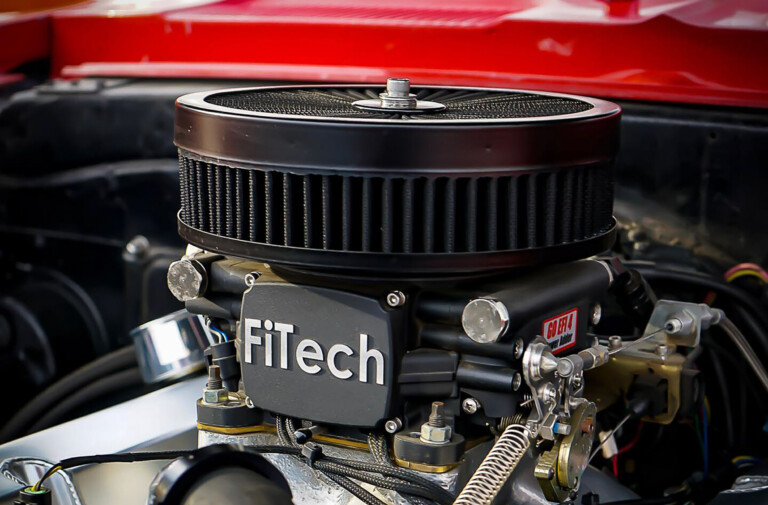

With the bottle mounted, the next steps of our install brought us under the hood of Project Blackout. We started things off by disconnecting the negative battery cable. Next, we located the throttle body and the four screws holding it on. Using a 10 mm socket wrench, we removed the throttle body from the intake manifold.

We slid on the nitrous plate with the side labeled ‘Intake’ facing toward the engine. We then used the supplied bolts in place of the stock throttle body bolts and hooked the PCV system back up. From there it was on to the solenoids. Using a small amount of liquid Teflon thread sealant, we tightened the NPT fittings on to each of the solenoids, blue for nitrous, red for fuel, and the ones with the screens on the side labeled ‘IN’ on the workbench. We then mounted the solenoids in the car, near the throttle body. There is no wrong place to mount your solenoids – just make sure that the supplied lines that run from the solenoid to the throttle body will reach.

After snaking the nitrous feed line coming from the bottle in the rear of the car, we attached it to the nitrous solenoid under the hood. Then we gave the fuel solenoid the same treatment, only this time using a line going to the fuel rail. We were very careful here as the fuel in the fuel rail stays under pressure even when you turn the engine off. We unscrewed the Schrader valve and let the pressure out before opening it up all the way.

At this point we needed to add some electrical power to our system. We started with the arming switch, installing it in the center console. Then we ran power through a relay to the solenoids after installing a fuse on the wire coming from the battery positive. The base kit also comes with a microswitch to trigger the nitrous solenoid at wide open throttle. Because we were installing a progressive controller it was not necessary for us to install this component or any of the relays or switches, but here is what the normal wiring diagram looks like for the plate kit:

To keep things tidy, we installed the switches for our system inside the center console between the seats, within easy reach of the driver.

Under Control with the P.O.D. System

As mentioned before, bottle temperature effects bottle pressure – which effects performance. So we looked for a way to not only monitor bottle temperature and pressure, but adjust said variables if need be. The NOS Pressure On Demand System lets you do just that. In order to complete this phase of the installation, the following tools were used:

• Flat tip screwdriver

• Socket set

• Wire Crimper/Cutters

The POD system consists of four main parts: the bottle opener, a bottle heater, the main controller, and an LCD display. It uses two sensors to monitor temperature and pressure and display information about the condition of your nitrous bottle. From there you can set the system to whatever pressure you desire and the POD will automatically cycle the heater to maintain pressure based on the conditions you’re facing at the track that day, all while you are sitting in the driver’s seat waiting in the staging lanes.

The bottle opener was the first thing we started with. To correctly attach it to our bottle we used a flat tip screwdriver and removed the cap from the bottle. Then, while being careful not to open the bottle valve, we used a half-inch socket and loosened the nut on the valve handle and then removed it. Our kit came with a special gear that is mounted on the bottle for the opener to turn, which installs in place of the standard valve handle. We picked up our flat tip screwdriver again and used it to crack the bottle open and quickly closed it. This is to make sure that the valve was not over-tightened when last shut, making the bottle opener unable to turn the valve.

The bottle opener slid right on where the original valve handle was. We made sure that the gear we installed on the bottle meshed well with the gear on the motor. Then we tightened everything down and moved onto mounting the pressure transducer.

The pressure transducer may sound like a spacecraft component, but it’s nothing more than an electronic pressure sensor that tells the Main Controller what the bottle pressure is at. Installing this component requires that you screw it into the nitrous bottle gauge port at the top of the bottle, so make sure you do it before you get the bottle filled. The transducer has to be directly connected to the bottle, rather than attached down-stream of the valve – otherwise, the controller won’t know what the actual bottle pressure is when the valve is closed, which can lead to overheating. Always use Teflon paste, never tape, on the sensor threads to prevent any leakage. Shreds of tape can make their way into the system and clog jets, so save that roll for the next time you’re under the sink. Then we hooked up the main controller to the opener and pressure sensor next to the bottle. Finally, we wrapped up the bottle with the bottle heater and attached the two wires to the main controller.

From there we only had a few more wires to run including power, ground, and one going to the LCD display that we put in the glove box. That’s all. We tested everything out including the opener and pressure sensor when we filled the bottle and it all worked flawlessly.

Making Good Progress – Mini Two Stage Progressive Controller

If the plate kit is the heart of the operation, then the Progressive Controller would have to be the brain. Unlike just using a simple microswitch on the throttle body, the progressive controller allows you to fine tune your nitrous flow to have the right amount of power when you need it – as opposed to all at one time. The controller can be activated one of two ways; either by using a TPS signal or a microswitch under the pedal or on the throttle body. We chose to trigger the device based on the TPS signal. “Using the TPS sensor is a more accurate way of sensing throttle position compared to a micro switch,” explained Tichenor. “It allows you to start ramping the nitrous at any throttle position.”

The NOS Progressive Controller combines a TPS switch, two progressive timers, and two RPM window switches into one small unit that can be mounted almost anywhere in your vehicle. We decided to use the TPS function on the unit along with only one of the two stages of nitrous. Being that this is a streetcar, we saw no need for a second stage – at least until we upgrade the transmission and torque converter.

Under the hood we started by hooking up the TPS signal first. We spliced into the signal wire coming from the TPS and connected that to the green wire coming from the controller mounted in the glove box. Then we grabbed the ground wires from each of the two solenoids and routed them to the corresponding wire coming from the controller. One thing that should be noted is the unit’s ability to trigger two external devices such as an ignition timing retard or a methanol injection system. We haven’t outfitted our vehicle with anything such as that so we just taped the wires off for possible use later.

Setting up of all of these components is super-easy. All the devices have menu-based settings that are not only easy to navigate, but easy to change as well. The progressive nitrous controller can sense a wide variety of different tach signals, but be careful to make sure you’re programming it correctly – we ended up in “4 cylinder mode” to get the correct tach reading.

Track Testing Results

As we said at the beginning, our goal for this upgrade was to see some meaningful improvements at the dragstrip. We took a drive to Irwindale Speedway, an 1/8-mile track just outside of Los Angeles, to put the NOS system to the test. To make sure that we were comparing apples to apples, we made a few non-nitrous passes to see where we were at that day. We ended with a best naturally-aspirated pass of 9.2 at 78.47 mph. Here’s a look at the incrementals:

Best NA 1/8 Mile Pass

60 foot – 2.110

330 – 6.037

1/8 – 9.200

MPH – 78.47

After pulling around back into the staging lanes, we popped the hood, grabbed the POD controller, and set the bottle pressure to 950 PSI. Then we used the Progressive Controller to dial in the ramp for our nitrous system. We set it to begin injecting nitrous at 3500 RPM at 49% of capacity and ramp all the way up to 6400 RPM. That way the nitrous wouldn’t hit too soon and spin the tires, but not late enough that we wouldn’t be running it through the transmission shifts.

After a few tries the TrailBlazer SS recorded a best nitrous pass of 8.449 at 78.47 mph for a gain of just under .8 seconds and just over 8 mph – impressive numbers in the eighth-mile.

Best Nitrous 1/8 Mile Pass

60 foot – 2.107

330 – 5.622

1/8 – 8.449

MPH – 86.88

The NOS LS2 plate kit is a simple install that has the potential to help you drop some serious time off your ET’s and add a few MPH to your trap speed when used correctly. The easiest way to make sure the system is at its best is with the use of the POD and Progressive Controller, not only to keep the system operating under optimal conditions, but to fine tune it to deliver the right amount of N2O to keep your car digging down the track without breaking the back end loose. It would take about a day to install these kits in the driveway; a day well spent if you ask us. NOS’ kits make nitrous not only easy, but safe to install. We are going to be doing lots more testing as time goes on using the Progressive Controller to really dial in our nitrous to see if we can bring down those times even more.