There are numerous options on the market when it comes to crankshaft dampers. This product is something that many will take for granted, as long as it fits the car, has an SFI stamp, and you can bolt the proper accessories to it, most will give this part little additional thought. By neglecting this area of the engine however, you risk several things.

The first is engine performance. There is actually power to be gained in many instances by using the proper damper. The second is engine longevity. By not properly damping the vibrations and twist caused by crankshaft rotation, and the internal combustion cycle, parts will become fatigued, and fail faster.

Last but not least is safety.

In this tech feature, we’ll be taking a look at ATI Performance Products’ line of custom dampers for racing applications and the technology that’s gone into their design that will ensure that you, your pocket book, and the race fans around you are kept safe when the light turns green. Especially when building a unique combination that in turn requires a unique damper, we will show you some of the options available.

The Effects of an Incorrect Damper

This cutaway views shows you the elements of ATI's traditonal dampers that are built upon an elastomer design.

A failure on the track — especially at high speeds — of a poorly built or improperly used damper presents several dangers. Parts of the failed damper can be thrown from the car, or into other components, doing further damage to the car, the racing surface, or worse: spectators. Your engine’s rotating assembly can suffer catastrophic failure, and this could result in an engine that suddenly seizes, vibrates itself into a harmonic type of failure, or throws oil all over the track because of a punctured block. At a minimum in this type of occurrence your race weekend may be over, and the track may be down for clean up of either your failed parts or even your wrecked race car.

The result of a damper failure is never pretty. In one instance your writer actually witnessed a piece of a failed OE damper on a supercharged car bounce off the track, over the shoulder of another photographer, and strike the hand of a spectator standing at the fence. Fortunately for that young lady a quick check by EMS found that she suffered no serious or lasting injuries. Had it struck her in the head or chest, the story may have been much different.

Further adding to the mix in all of this are the additional stresses placed on the crank snout and damper by accessories being run off the crank. There are of course the typical engine accessories, some of which are still run in racing applications. Then there are the racing applications, crank triggers or trigger wheels, supercharger pulleys, oil and fuel pump drives and the like. All of these items place additional stress on the crank snout and if bolted to the damper then the damper assembly itself.

Measuring Twist

To construct a proper damper you must first have an understanding of what damping actually is.

The culprit in an internal combustion engine is crankshaft twist, which causes the “harmonics” or vibrations. This measurement can be expressed in degrees of twist, where the crankshaft during a combustion event twists one way past it’s natural state, and then it’s momentum carries it in the opposite direction again past it’s natural state. This means that your crankshaft is acting much like a spring – if the spring flexes and bends too much it will deteriorate, fatigue, and break. The damper’s job is to counteract this twist as much as possible, turning the twisting energy into heat. Without a proper damper, engine failure will occur much more rapidly as the crank literally shakes and twists itself apart.

We sat down with JC Beattie Jr. at ATI to gain a better understanding of crankshaft twist and how ATI constructs it’s dampers to counter this twist and provide custom damper solutions to their customers. Beattie has over sixteen years experience measuring crankshaft twist and designing dampers. He works closely with some of the biggest names in engine building, including every engine builder for NASCAR’s Sprint Cup series. Beattie has also written several articles on proper damper design and how ATI designs their dampers.

Customizable Dampers

ATI builds their dampers using an elastomer design. It was actually found and published in an SAE paper written by R.C. Bremer Jr. in 1979 that an elastomer-style damper is a strong method for controlling crankshaft twist. We’ve talked extensively about damper design before, so we won’t be going in depth with that here.

The way ATI builds their dampers, however, offers racers and engine builders a wide array of customizable options. “If you can think it up, and it will fit one of our standard damper designs in terms of horsepower and RPM, we can build it,” says Beattie.

We utilized an ATI Super Damper on the 500 cubic inch LS7 powerplant that Late Model Engines constructed for one of our LSXTV project vehicles. The damper ia assembled using a steel hub and an aluminum balancer and incorporates a six-inch dry sump pulley.

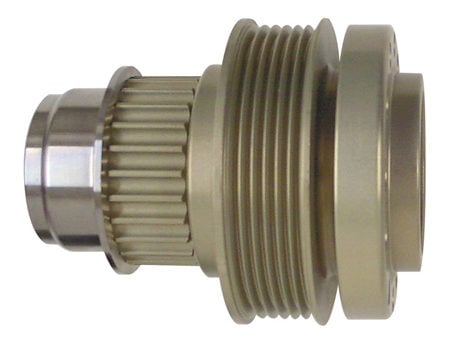

ATI Super Dampers are constructed using a multi-piece design. Depending on the application this design consists of a hub, an inner shell, the inertia weight, and the outer shell. The inertia weights, elastomer type, and shell sizes can be tuned for each individual application. On some designs the inner shell and hub are combined into a single piece. Also on some import designs where the damper is a friction fit, bolted to a timing gear, and only secured using the single crank bolt, ATI constructs the timing gear and hub as a single piece, eliminating the poor fit design of the OEM.

Engine Swaps/Custom Shells

If you can think it up, and it will fit one of our standard damper designs in terms of horsepower and RPM, we can do it. – JC Beattie Jr.

“We make custom hubs to put the damper on any engine. We can custom build a damper that you can swap the shells back and forth,” Beattie explains. Time matters in the pits on race weekends; when you’re trying to go rounds and win titles, in the upper echelons of the racing world, engine swaps or pulley changes are inevitable. Custom hubs and shells can be tailored for racers who perform frequent engine swaps. By having a single hub for each engine, the damper can be swapped to a backup engine quickly and easily without the need to fully remove it.

This may come in handy especially for custom applications that incorporate a belt drive into the hub for timing belts. This again goes back to the customizable design and rebuildable nature of the ATI Super Damper. Having the ability to swap the outer shell only also means that you can change your drive blower pulley diameter if necessary. You would simply need to swap the outer shell of the damper to the one with the proper configuration. Again, this is potentially time-saving during vehicle maintenance or on a race weekend.

Custom Key Ways

Whether you need multiple key ways due to your engine’s performance demands or supercharger/blower application, or your OEM engine is a friction fit design, ATI has a solution.

Some OEM’s have actually gone to a slip or friction fit-style damper. They have eliminated the keyway itself, relying instead on a tight fit and friction, along with a single crank bolt to hold the damper in place. While this design will work for cars that are simple run-of-the-mill daily drivers, it does not work well at all in high performance, forced induction or high-RPM applications. In these types of environments the damper can actually slip or even come off the crank all together.

Think about the tremendous RPM range of some high performance engines, shrieking past 7,000 RPM and beyond. When those engines coast down, or experience rapid gear changes which then cause rapid changes in engine RPM, under continued stress at these speeds, something will inevitably give. A slip fit damper simply would not be the best choice in this type of application.

The Keyway Solution

Some LS and New Hemi engines use a friction fit damper with no keyway incorporated into the crank snout. This damper is held in place by friction, and a single crankshaft bolt. This is fine for your grandma’s 300C, however, if you intend to increase the performance of those vehicles, especially through supercharging, a better fitting balancer is a wise and almost mandatory investment. This tool kit from ATI includes the necessary parts including a fixture and drill bits, that allows the crank snout to be properly drilled to accept pins. These pins will properly retain the balancer in the absence of a keyway in high performance applications.

Further consideration should be given to the loads placed on an engine by belt driven items. While race engines for the most part keep accessories to a minimum, there are things like the oil pump drive in dry sump applications that rely on the connection to the crankshaft to keep the engine lubricated.

Also to consider would be the load placed on the damper and crank pulley by a supercharger. Both during engine acceleration and deceleration, as well as belt tension in general. There are instances where the blower speed does not match engine speeds in terms of how it is driven. Given the extreme loads that this can place on the front of the crankshaft, a slip fit damper would seem a poorly thought out design for such an application, as would a single keyway design.

Beattie tells us, “I won’t build a slip fit damper. I do get requests for it but there’s not enough surface area for a good fit.” The company instead offers multiple solutions for either fixing the slip fit damper problem or placing multiple keyways in a damper to allow it to fit more securely. Consider that under the tremendous loads of a high output race engine a single keyway may also not be enough to securely hold a damper in place in the long term.

For engines that were originally equipped with a friction or slip fit damper, ATI offers dampers that will accept a keyway or pin. The company offers a fixture and detailed instructions for modifying the crankshaft snout to accept one or more new keyways.

In performance and racing applications ATI can design the hub of their dampers to accept multiple keyways, which again this goes back to the multi-piece design of their dampers that allow for the right parts to be combined to create the proper solution for an engine. Most supercharged engines should run two keyways. This reduces stress on the snout of the crankshaft, reducing the possibility that it may break at the keyway slot. This also ensures that the damper stays in place and that its hub is not damaged due to the loads placed on the crank and the keyway that’s preventing the damper from rotating on the snout.

Blower Drives

Supercharger drives have traditionally relied on pulleys provided by the supercharger manufacturer. The crankshaft pulley is bolted to the front of the damper or crank pulley, which can place additional stress on the crankshaft snout. ATI can incorporate the blower drive into the damper shell as well. Beattie tells us that in some cases “we’ve put 99 teeth on a damper shell”. The diameter of the blower drive can again be varied based on your engine and specific needs. The depth or width of that drive can also be varied to accommodate your specific belt needs.

ATI can incorporate a wide number of options for the crank portion of a blower drive into their Super Dampers. Efforts are always made to place the teeth for the blower belt as close to the engine as possible to reduce stress on the crank snout.

All ATI blower dampers come standard with two keyways. Pulley offsets are typically set up by ATI to place the blower pulley as close to the engine as possible This will reduce bending at the crankshaft nose by shortening up the lever affect that many tight supercharger belts have against the crankshaft snout. This eliminates the needs for adding additional pulleys on the front of your engine. It ultimately can allow for more room or clearance in front of the crank. There’s also potential for a reduction in weight, number of parts, and clutter.

Belt Drives

When you think of belt drives, timing belts, serpentine or accessory belt drives as well as oil, fuel and vacuum pumps all come to mind, and all can be configured to work in conjunction with ATI’s custom dampers.

Camshaft Drives

ATI’s dampers are configurable for all of the major belt drive systems. Whether for an import or domestic engine that was already equipped with a timing belt, or a high output racing engine. ATI can build a damper for OEM timing belts, or aftermarket systems such as Danny Bee, Comp Cams, Jesel or other type of timing belt system.

These systems are built into the hub portion of the damper and can be custom tailored for the diameter of the belt drive as well as the number of teeth on the crank gear. This further eliminates the total number of parts that have to be attached to an engine, thereby reducing clutter, complexity and in some cases, weight on the crank snout.

Custom Accessory Belt Drives

Serpentine belt and accessory belt drives can be incorporated into the damper shell and custom tailored as well.

“If you want to run a big block Chevy snout on a small block Ford, we can build the hub for that.” explains Beattie. This then opens up the options on engine swaps as well as what accessories or parts can be run on the engine.

Dampers such as this Gen III Viper (left) or Miata (right) incorporate the serpentine drive into the shell.

Many newer engines also incorporate the serpentine drive/crank pulley into the damper, rather than earlier model designs where the crank pulley simply bolted to the front of the damper. ATI has this covered as well, offering applications where one or more belts can be run from their damper shell.

Pump Drives

For those running dry sumps or crank-driven fuel pumps, ATI can take this into account when building a custom damper as well. The company offers the drive mandrels for many popular applications, including Chevy, Ford and Buick. The damper configuration can be tailored to take into account running these systems as well so as to ensure proper clearance and damping.

Custom Balancer/Pulley Widths

Pulley widths can be varied based on an engine builder’s specific needs. With respect to the actual size of the damper Beattie says, “Our thinnest damper is 1.02-inches, our heaviest is two inches wide…maybe a little wider in an eight-inch diameter.”

On this topic Beattie explains, “The only real constraints we have are the outside diameter and the distance to something that has interference.” So it really comes down to how much room do you have? When you get into imports, front wheel drive, and all-wheel drive vehicles where the engine may be mounted in a front wheel drive configuration, clearance becomes a bigger issue as you have to contend with frame rails or suspension components.

The only real constraints we have are the outside diameter, and the distance to something that has interference.” – JC Beattie Jr.

This is one area where you run into greater limitations on what can be done in terms of the pulley width or depth. The same would hold true when running a rear wheel drive configuration in a tight engine compartment. Items like radiators, hoses, fans and other accessories may simply not allow for adequate clearance. The vehicle’s own space constraints are the ultimate limiting factor.

Crank Triggers and Magnets

Crank triggers are nothing new in the racing world. Having been used for years to trigger ignition components or even in data logging and EFI control systems, these systems typically rely on a pickup wheel of some type.

That pickup wheel in most cases must be attached either to the front of the damper or installed between the damper and timing cover in some applications. This is another additional part that ATI can eliminate and incorporate into the shell of one of their custom dampers.

Dampers constructed with an aluminum outer shell can contain as few as one or up to 28 magnets in an eight inch design. The pickup for these triggers may need some minor modification since placing the trigger magnets inside the damper shell could possibly change the distance from where the pickup would typically mount, either moving it closer or further away.

Magnets can be incorporated in varying locations or degrees and the design should be compatible with a wide variety of ignition or even data logging systems.

Racers are always looking for simplified solutions to complex problems weight savings, engine longevity, and space savings are just a few issues that a custom built damper may be able to help with.

There are a lot more options available for custom dampers and ATI’s web site has a form to fill out for racers and engine builders looking for a custom built damper if it’s something that your engine program is lacking. This small part with potentially huge impacts on engine operation has been overlooked by many in the past. It could be what your engine program is missing to simplify servicing between rounds or races, improve engine longevity, and possibly get you in the winner’s circle more often.