It’s no secret that General Motor’s supercharged 6.2-liter LSA V8 is becoming an increasingly popular powerplant for swaps into not only vintage rides, but late-model vehicles as well. Offering 580 horsepower and 556 lb-ft of torque (in fifth-gen Camaro ZL1 configuration), along with the factory-backed support of Chevrolet Performance’s Connect & Cruise powertrain system, it’s no surprise that this proven powerplant has become an attractive option for builders looking to capitalize on the Big Three’s modern horsepower arms race while adding the kind of reliability and efficiency that enthusiasts could only have dreamed about back in the day. It also doesn’t hurt that the LSA is available at a significant discount compared to the LS7 and the LS9.

While Chevrolet Performance has done a great job supporting enthusiasts who are embarking on these projects, there are some aspects of these swaps that require builders to look to other sources for solutions to specific issues.

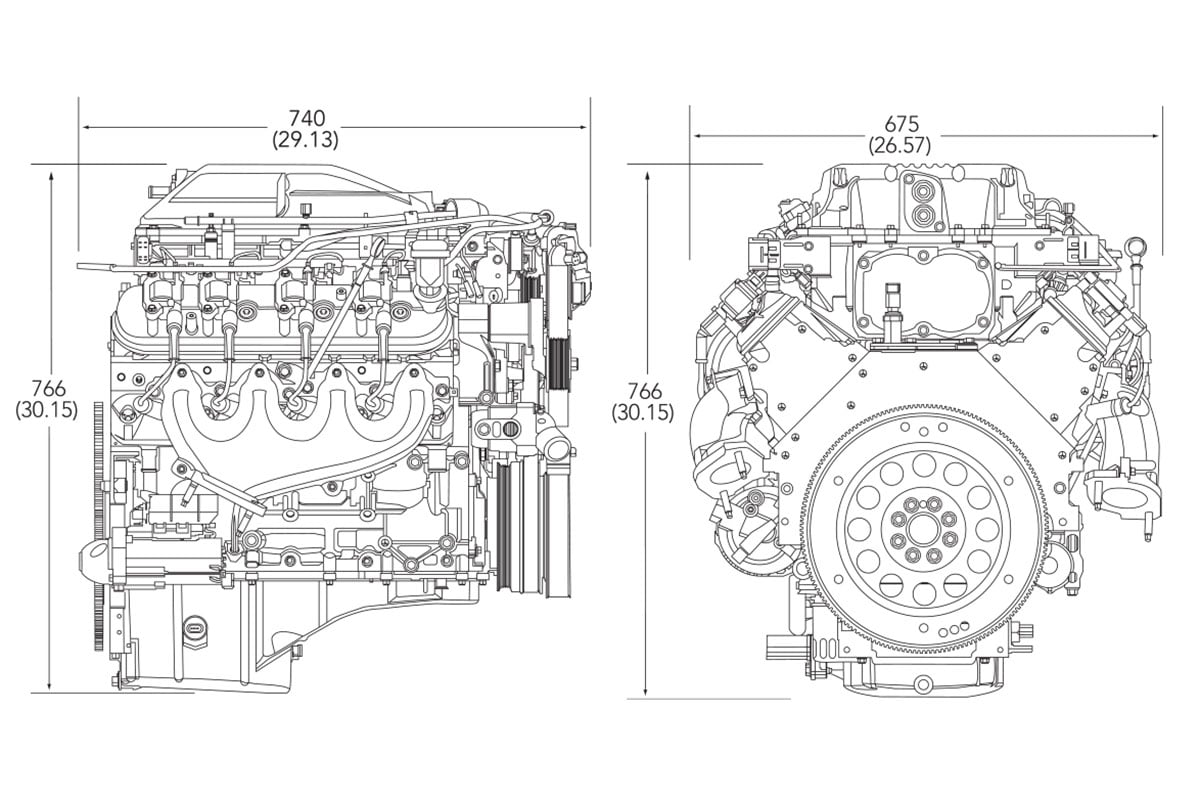

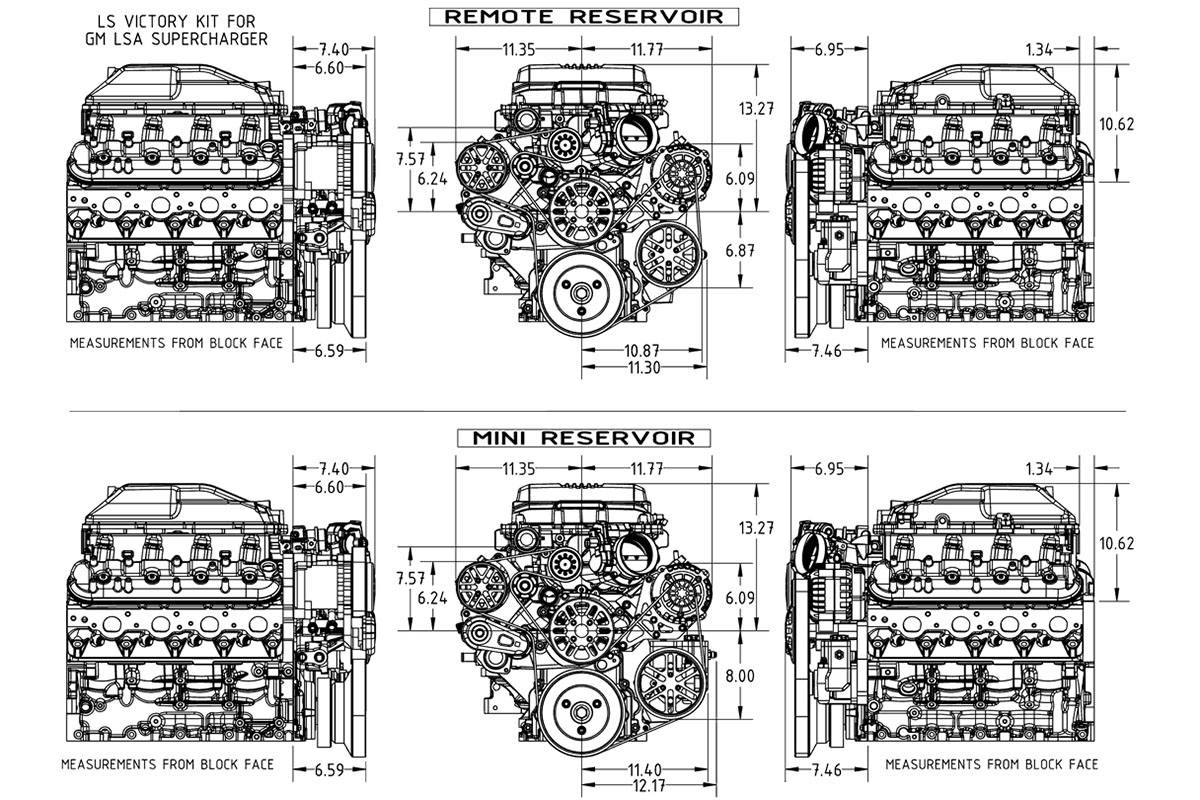

In the image on the left we have the dimensions for the GM LSA engine in factory configuration. On the right we have the dimensions of the Concept One Victory Accessory Drive Kit itself as well as the overall dimensions of an LSA engine with the Concept One kit installed.

For us, that specific issue involves the low-mounted air conditioning compressor used with the LSA. This design can often present a packaging issue in swap projects, as it did with our 2008 Chevrolet Trailblazer SS. We lived without the luxury of air conditioning in the truck for a while, but with temperatures regularly exceeding 100 degrees in the region where this TBSS lives, this proved to be an amenity that we could forego no longer, so we turned to Concept One and the Victory Series LSA Accessory Drive system (PN LSV01 SC03) for a remedy to the problem.

A few months ago we gave you a teaser look at this kit, and now we’re back to provide a closer inspection of the hardware involved in the project, as well as detail the installation process itself.

Solving Interference In Style

“The main reasons you would need one of these pulley systems are fit and clearance,” explains Kevin Redd of Concept One. “The factory pulley system was made for a late-model vehicle, which means the A/C compressor is mounted down low on the passenger side of the engine. A lot of the older vehicles that people are putting the LS engines in have crossmembers that will interfere with the compressors mounted down low.”

With LSAs finding new homes in everything from our late-model Trailblazer to ’72 Chevelles, it’s essentially impossible for one kit to serve as a universal solution for packaging issues, but the Concept One system does have the potential to solve a lot of headaches for builders doing this swap. “Our kits are built around putting the LS engines in the older cars from the 1930s through the ’70s,” Redd tells us.

Concept One's front drive kit for LSA swaps are made to order for each customer's specific application, allowing them to choose from various components from manufacturers like Edelbrock, Powermaster, Delphi, Continental and Tuff Stuff. This modularity not only ensures that the kit will work with a specific install, but that the parts included are tailored to the needs of a particular build.

“However, our LS pulley systems are designed to fit virtually all of the LS engines. There are some different variations, but we can accommodate most of them. We didn’t necessarily build them for the later model applications, but with the popularity of the LS engine we’ve seen customers put them in late-model swaps.”

Our kits are built around putting the LS engines in the older cars from the 1930s through the ’70s. However, our LS pulley systems are designed to fit virtually all of the LS engines. We didn’t necessarily build them for the later model applications, but with the popularity of the LS engine, we’ve seen customers put them in late model swaps. – Kevin Redd, Concept One

Of course that doesn’t mean that builders are left to sort out a fitment solution on their own. “We offer many options that help us tailor each kit to the buyer’s specific needs so they are built specifically for that individual’s project,” he adds.

The Concept One kit features hardware from brands like Edelbrock, Powermaster, Delphi, Continental and Tuff Stuff – companies who’ve built reputations on providing high quality components to consumers. Not only does that offer piece of mind to builders in terms of the durability and build quality of the parts they’re installing, it also ensures that the kit is backed by top-notch support in case it is needed.

“Some might say, ‘Well why would I want to pay more for a name?’” Redd posits. “The reason is that these folks built their companies around quality, and that is how they have stayed in business for many years. Also, let’s say we have an electrical problem. We, at Concept One, are good at doing what we do, but we are not electrical experts. So if a customer is having electrical issues, we can send them to Powermaster’s professional tech line to help figure out what is causing the problem, rather than just throwing parts at it hoping to fix the problem.”

Along with the component customization choices available, Concept One offers some aesthetic options as well. Four different finishes for the pulleys and brackets are available--machined, polished, black hard coat anodized and clear anodized--while other components like the alternator, power steering reservoir and A/C compressor are available in multiple finishes as well.

The modularity of the Concept One kit allows builders to get a package that’s tailor-made to their application both mechanically and aesthetically. “For instance, we’ve noticed a younger generation of car guys want to run a lot more electrical components on their cars so they need much higher amperage alternators to operate these systems, so we offer several different options of alternator to fit the customer’s needs,” he says.

“We also offer more options for power steering pumps – whether you are running a stock steering gear, Fox-Body style rack and pinion, a new Delphi steering gear or Hydro Boost – we can set the power steering pumps for flow rates and pressure according to their needs.”

Not only does the Concept One kit make running accessories like the air conditioning possible on vehicles where the compressor’s stock location makes that impossible, it also sharpens up the engine bay’s look as well. And if you’re putting an LSA into an engine bay that didn’t originally have one, you’re probably going to want to show that off.

The pulleys and brackets in this accessory drive kit are also offered in a choice of four different finishes to ensure that the look of the package jives with the rest of your project’s aesthetic.

We opted for the standard pressure power steering pump with the billet reservoir, a polished compressor, and a Powermaster alternator (AD244). Also, it is important to note that factory wiring harnesses like the one found in this Trailblazer require the two-wire plug for voltage regulation in the ECM. The voltage will affect parameters for a number of vital components (the injectors, for instance), so getting this right is crucial.

Ditching The Rattles And Slips

The factory-installed isolator coupler has earned a reputation for getting loose and making noise even on low mileage Camaro ZL1s and Cadillac CTS-Vs, so we decided to correct that issue here with Lingenfelter’s 10-bolt supercharger pulley hub and isolator coupling, which are compatible with both LSA and LS9 motors.

Since the factory isolator coupler is known to start rattling early in life, we took the opportunity to address that during this accessory drive installation project as well. To address this we turned to Lingenfelter for its supercharger hub and isolator coupling (PN L250150309 and L960202012, respectively).

We also turned to local performance outfit ZPE for one of its Griptec supercharger pulleys. While Concept One provides a blower pulley with the front drive kit, ZPE’s Griptec design offers some compelling advantages over conventional pulleys.

“You don’t want to create a surface so aggressive that it will damage the contact material – in this case, the supercharger belt,” says ZPE’s Andrew Zimmer. “So you have to set up the serrations so they can penetrate deep enough into the belt to create a sort of cog effect without running the risk of deteriorating that belt material during the stresses of operation.”

The upshot is that the Griptec design can more effectively prevent belt slippage – and a drop in boost pressure in turn – while not prematurely chewing up blower belts as a result.

Belt slip is a very common issue on supercharged components. ZPE's Griptec pulley is designed specifically to eliminate that issue. ZPE's multi-directional machined ridges and valleys also act as escape ducts for trapped air and debris, further improving contact between target surface and belt.

Though we were losing a little boost overall and going from a dedicated supercharger belt to a single 8-rib belt for everything, we theorized that the Griptec piece could offset some of those performance disadvantages from the previous setup. We also looked into using a Kevlar Gates/RPM belt but they didn’t have any in the size we needed, and the Continental belt included in the Concept One kit is a high quality piece to begin with.

The final ancillary part to this equation was an Airaid throttle body spacer (PN 250-634). While Airaid touts performance benefits from the spacer’s “Helix Bore” design, which is said to shape the incoming air for more efficient combustion, we were actually more concerned with packaging issues, as the spacer provides adequate clearance for the pulley and the electric motor on the LS3 throttle body used on our build. The Concept One kit is designed for the standard LSA throttle body, which has a much slimmer motor than the LS3’s.

Installation

As one might expect, getting this installation underway involves the removal of some of the factory parts that are going to be swapped out for the components included in the Concept One kit. We started by draining the radiator, then removing the air intake and water pump, along with the idler pulleys and their associated bracket. After using an air chisel to loosen it up, we used a puller on the balancer.

After draining the radiator and getting the cold air intake and few other components out of the way, we were ready to start bolting on the new parts. The new balancer uses longer bolts with shims used to seat it. Note that the LSA engine has a keyway on the crank, unlike other LS engines. In this install we also re-used the ARP balancer bolt after applying some red Loctite.

Installation of the new water pump is a straightforward process of removing the factory pump and installing the one sourced from Concept One. Once we knocked that out, we moved on to the unhooking and draining of power steering components and removing the old alternator.

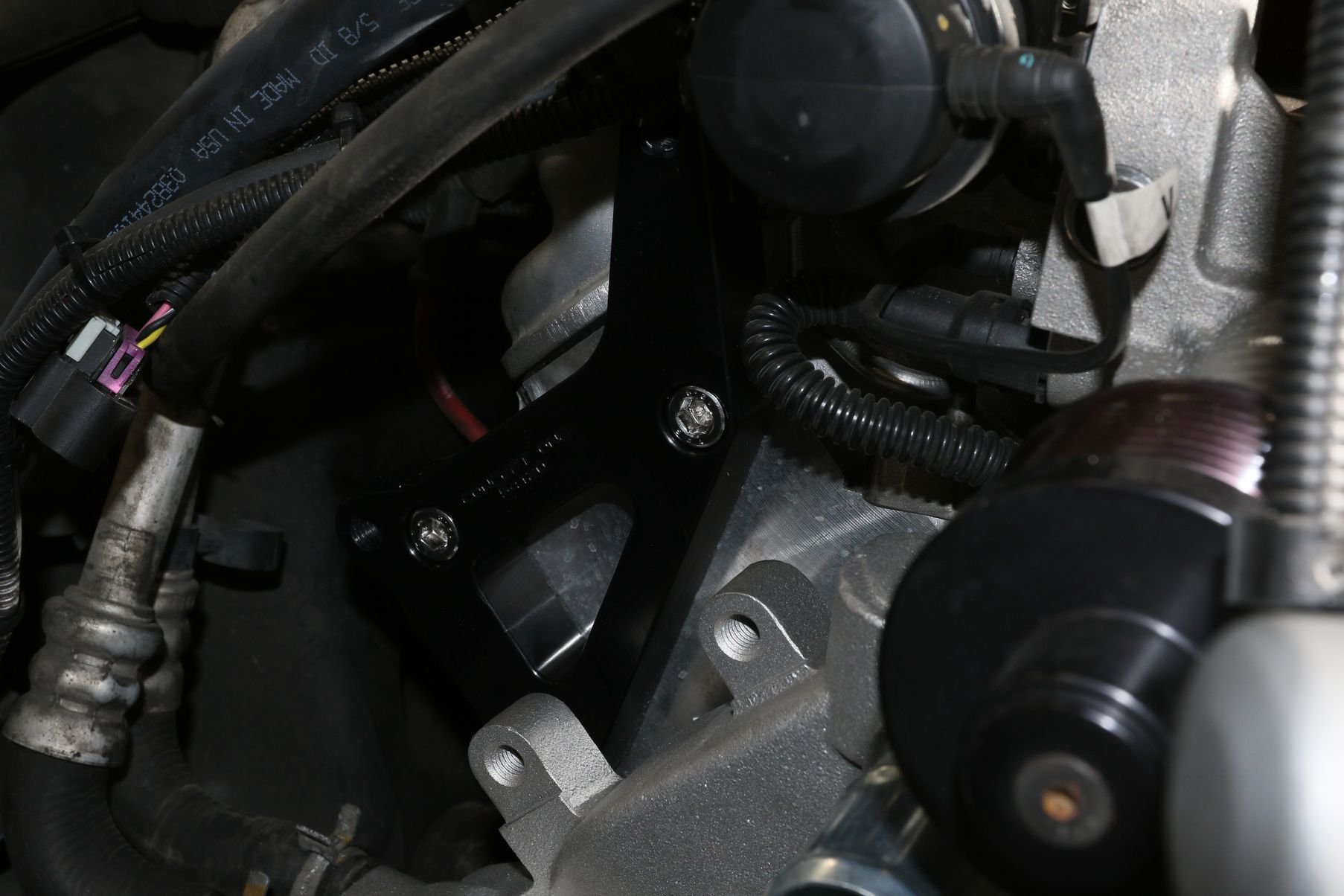

The billet brackets are bolted up to the cylinder heads and block, in turn providing a mounting point for the accessories we'd be installing next.

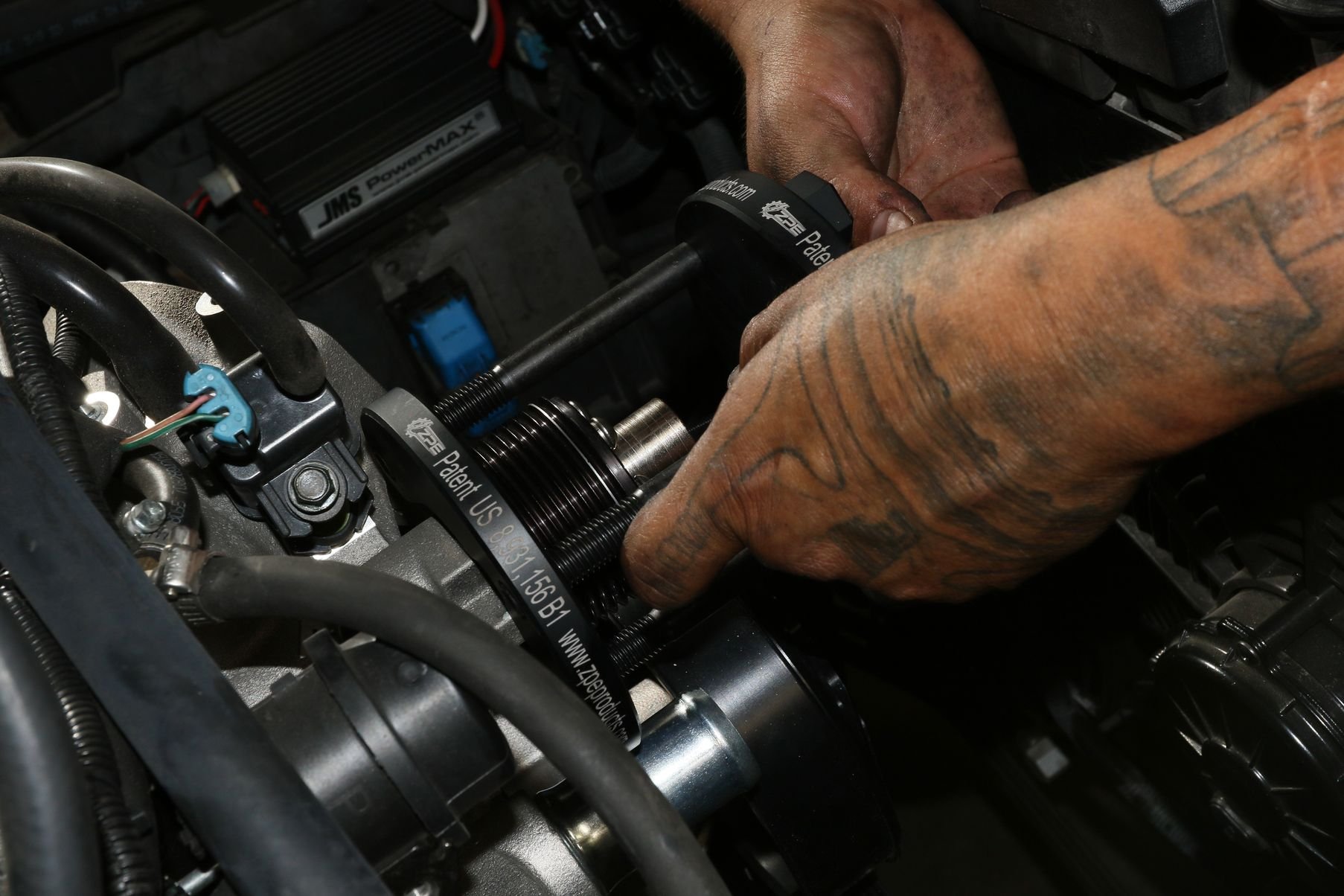

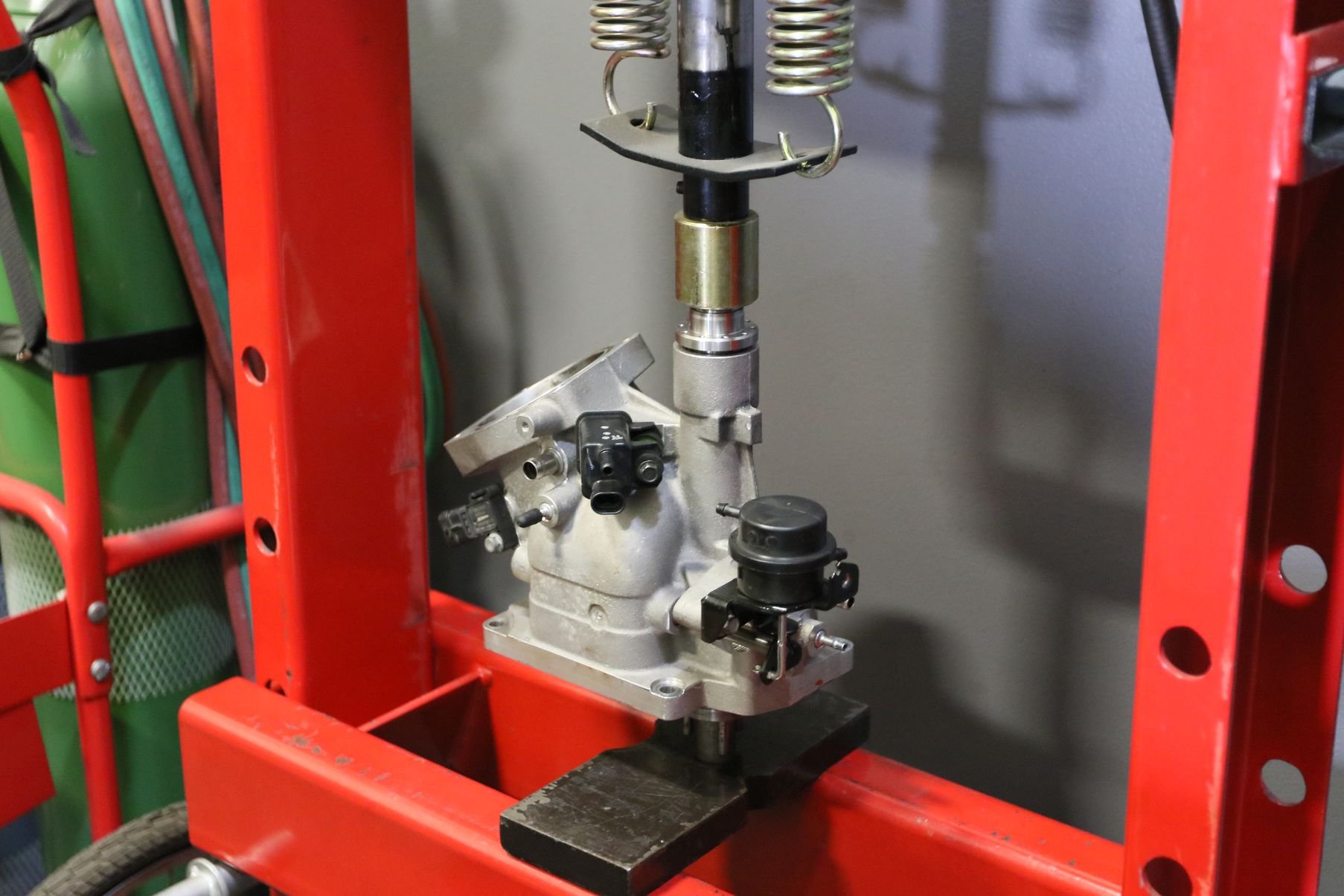

From here we turned our attention to the supercharger pulley. ZPE included a removal tool with the pulley, but since the one we were removing was also an aftermarket piece it was particularly tough to free from the supercharger, so we ended up using a different removal tool here.

After unbolting the supercharger lid so we could remove the supercharger and its factory hub, we pressed on the Lingenfelter piece. Once secured, we reinstalled the supercharger and buttoned up the lid.

After removing the factory supercharger pulley, the installation of the ZPE pulley, along with the Lingenfelter hub and isolator coupling, were next. The new hub is installed with a press. After adding the Airaid throttle body spacer to clear the pulley and LS3 throttle body motor, we needed to fabricate a new portion of the air intake tubing to make it all fit.

Since the power steering reservoir is remote mounted, we made some custom braided lines to send fluid to the tank using some extra Fragola lines we had in the shop. Designed for motorsport use, these lines are reinforced with corrosion-resistant type 302 stainless steel wire braid and have an operating range of -40° F to +300° F, so they should certainly be up to the task.

A look at the braided Fragola lines we used for the power steering reservoir (left), and the custom A/C lines.

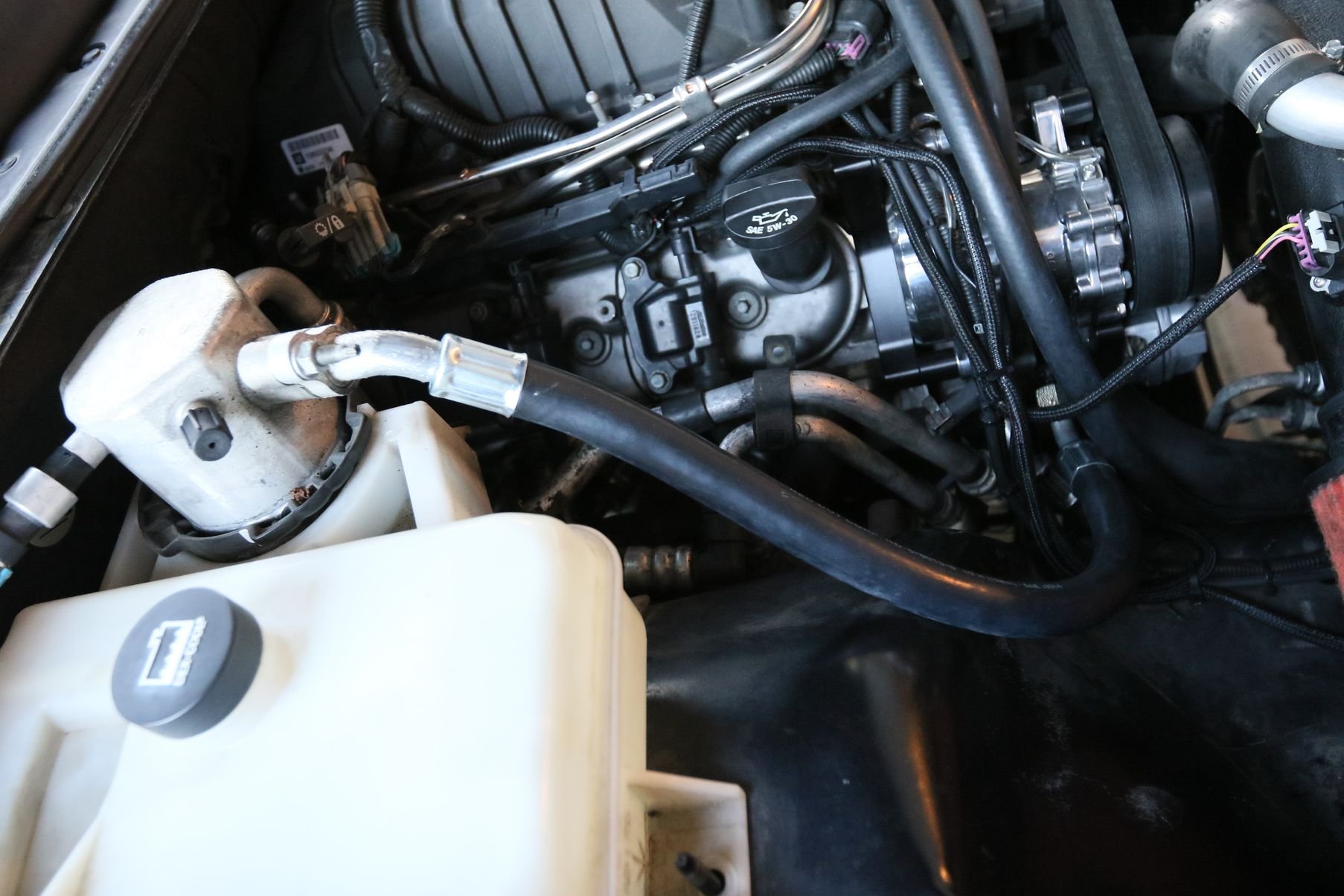

Last up were the lines for the air conditioning system. This step is trickier with late-model vehicles because it required us to custom make the A/C lines using a factory line while also ensuring that the pressure switches were kept intact. Without the pressure switches functioning properly the air conditioning system won’t turn on, a fact we discovered the hard way after a local A/C shop made the lines without one.

After several years of stock daily driving duty, this Trailblazer SS was ready for a shot of adrenaline. After a Flex Fuel conversion by Kraftworks it soon received the LSA transplant. Outfitted with a ported manifold and ported snout from Weapon X Motorsports, a ported LS3 throttle body, Comp Cams camshaft, Kooks 1 7/8-inch headers, and a handful of other go-fast goodies, it made over 600-rwhp on E85. But with southern California summers as hot as they are, it was soon obvious that air conditioning needed to return to the fold, and the stock setup would not work with the packaging constraints of the truck’s engine bay.

With everything said and done, the Trailblazer has a rattle-free LSA humming under the hood and an air conditioned cabin to help keep things comfortable as we wind down the hottest southern Californian summer on record. While the TBSS is a stout runner as is, future plans may entail a swap to a TVS2300 blower for the additional displacement or moving to a Whipple unit, and the modularity of the Concept One kit should make either upgrade a relative breeze.

Working on an LSA swap and concerned about potential packaging issues? Give the folks at Concept One a shout and see how they can help ensure that the transplant goes smoothly. Don’t forget to reach out to Lingenfelter to resolve the rattling factory isolator coupler issue that’s common with the LSA, and nab one of those trick Griptec pulleys from ZPE to give the mod factory-like refinement from end to end.