When it comes to choosing wheels and tires for you drag car, there is a multitude of options out there. From high-dollar custom sets down to cheap Chinese knock offs and everything in between. So where do you turn when you want a high quality set of wheels and tires but you don’t want to break the bank? Well, we chose to turn to JMS Chips [2] for a set of their Black Chrome Avenger wheels, and to Mickey Thompson [3] for a set of ET Street S/S drag radials.

JMS is a well established and trusted brand in the automotive community, but you may know them more for their Mustang parts than for their GM or Camaro-specific components. They are looking to change that, however, with their new line of fourth-gen wheels designed specifically with drag racing junkies in mind. We decided to give them a shot when we felt the urge to take our resident fourth-gen Camaro racing.

The Car

You may have heard that LSX Magazine recently underwent a change in leadership. That change brought with it an opportunity to get our hands on some new iron. Specifically a 2002 Camaro SS that has a decent amount of mods already. Now, don’t get us wrong, this car is in no way an all out drag car…yet. But it does have some potential and we will be pushing it further and further down the performance rabbit hole in the coming months—so stay tuned.

The car comes to us with an assortment of modifications in-line with what most fourh-gen F-body owners typically start with. The car has received a full set of bolt-ons including: SLP [5] 1 3/4-inch primary tubing headers, 3-inch Y-pipe with high flow Magnaflow [6] cats, 3-inch stainless steel Magnaflow exhaust, SLP lid and smooth bellow, 85mm SLP MAF, ported and polished throttle body, and 4.10 gears out back.

It also has a reverse split-pattern cam from Thunder Racing spec’ing in at 230/224 degrees of duration and .575/.563-inch of lift on the intake and exhaust respectively. The cam is ground on a 111 degree lobe separation angle which gives the car a nasty little thump for how mild the cam is. The engine mods have this particular catfish putting down around 390 horsepower to the ground—not bad for a cam-only Camaro.

The suspension has been upgraded mainly with BMR [9] components and includes their torque arm, lower control arms, and pan hard bar; all of which are adjustable. Single adjustable KYB shocks man all four corners and the car is sitting on a set of Sportline lowering springs from Eibach [10]. Edelbrock [11] sub-frame connectors tie the car’s chassis together and a strut tower brace helps with deflection up front.

It is a great starting point, but we’ve got a lot more in store for this mild LS1 before we are happy. However, we decide to start with a little more traction before we dove head-first into giving the car more power.

Wheel Selection

When we decided that this silver bullet was ready for track duty, we knew that we were going to need a little more than the low-profile Michelin Sport Cup tires wrapped around the car’s C6 Corvette wheels to get us off the line. We also knew that we wanted a set of wheels and tires that the car could grow into.

Where we are headed with the car, we wanted to provide as much side wall as possible, since this is a 6-speed car. With that in mind, we opted to go with a 15-inch wheel out back for a nice tall side wall. This will give the car a better bite off the line, decrease the stress on the drivetrain, and give the tires a better chance to hook. We dialed up JMS and they sent a set right over.

Wheel Construction

We selected a set of JMS’ Avenger series wheels in black chrome—which is a beautiful finish that even these high resolution photos don’t do justice. As we previously mentioned, we went with the 15X10 out back and the 17X4.5 up front. However, JMS does offer the rears in a 17X10 as well. The rears feature 7.5 inches of back spacing which is perfect to bolt directly to the fourth-gen F-body, while the fronts measure in at 1.75 inches.

Not only are the wheels easy on the eyes, JMS uses a much more advanced casting process to ensure that the quality of the wheels remains high and that they fit correctly on applications such as this, where there is minimal area between the caliper and inner wheel barrel (more on that later).

“We use a casting process that is really similar to what most OE manufacturers use,” said Brad Grissom of JMS Chips. “We actually use the same company that Ford uses for all their cast wheels, so all of our wheels are up to OEM standards for fitment and strength.”

Brad explained to us that there are several different process when it comes casting wheels. JMS utilizes a high pressure casting method to ensure wheel strength while eliminating excess weight and material.

“Not many wheel manufacturers use a high pressure casting process because it can be vastly more expensive,” Brad said. “While you will see that there is a price differential when it comes to our wheels, for the strength you are getting, it is much more affordable than what you would normally see otherwise.”

“High pressure casting allows us to reduce the material thickness while gaining an incredible amount of strength versus weight”– Brad Grissom, JMS Chip

In a pressure casting process, molten material is placed under pressure and forced into a mold. This vastly decreases the porosity of the metal when compared to a low pressure casting—or gravity casting as it is more commonly called.

While it may seem counterintuitive, this actually helps JMS save weight on the wheels. The material may be more dense since it is more tightly grouped, but it allows JMS to create wheels with tighter tolerances. This allows them to use less material in critical areas while still retaining the overall strength of the wheel.

“High pressure casting allows us to reduce the material thickness while gaining an incredible amount of strength versus weight,” Brad explained. “Obviously a forged wheel is going to be stronger, but it is also going to be at least double the price, so we feel that these wheels offer the best combination of strength and weight for the price.”

GripTech Tech

One of the many reason we were drawn to the wheels was the fact that you can order them with a revolutionary new process called GripTec. This process uses lasers to create micro-welds across the wheel where the beads of the tires sit. This “welding” process creates a surface that we can only compare to grip tape on a skate board.

The process, however, doesn’t leave any residue behind and ensures that the tire won’t slip on what would otherwise be a relatively slippery surface. While this might not be a problem for your average street/strip warrior, as we add horsepower to our mule it might become one. This will ensure that no matter what we are doing with our wheels they will be up to the task.

A company called Z-Industries—based right here in our home town of Temecula—is responsible for applying the process to the wheels and their patented technology is being applied to supercharger pulleys as well.

We were told by Andrew Zimmer, owner and co-fouder of Z-Industries, that this GripTec technology has been used in applications that are running well into the 7-second range without so much as a hint of the tire spinning on the bead—a remarkable feat that was accomplished without the assistance of bead lockers.

Since the car will likely be driven to and from the track, we didn’t want to go with bead lockers since they are hard to balance and just so happen to be illegal for on-street use here in the great state of California. The GripTec process will allow us to run a street-legal wheel while putting every ounce of power the car makes to the ground.

Tire Selection

Once we had our wheel selection figured out, it was time to take a look at tires. As we mentioned before, the car is going to frequently make trips to the track under its own power, meaning we had to have a wheel and tire combination that could be realistically driven on the street.

Typically a bias ply is the order for a 6-speed car since they are typically more flexible and are better suited to deal with the shock load from releasing the clutch quickly. However, they are not well suited for street duties and we wanted a tire that we could feel comfortable running around on out on the streets. This lead us to choose a radial construction tire.

We turned to Mickey Thompson who suggested a set of their famous ET Street S/S tires for on- and off-track duties. These radial construction tires are described by Mickey Thompson as “a street tire that can be driven on the track.” All ET Street S/S tires feature Thompson’s sticker R2 compound that just so happens to be the same compound used on the some of the fastest drag radial cars in the nation.

This particular tire, however, performs well in both on-track and off-track conditions, requiring little to no burnout to give you massive amounts of grip. The improved ET Street S/S has a block and tread void pattern that will make sure we get to and from the track in one piece but we wouldn’t suggest putting them to the test in anything but dry conditions.

We selected ours in a popular 275/60R15 size, again to give our car plenty of sidewall to work with. This brings the tire’s overall height to 28-inches. Up front we selected Mickey Thompson Sportsman S/Rs in a 26X6.00R17 tire sizing. Normally we would have gone with the 28-inch tall tire up front to match the rear, but with our car sitting on lowering springs, a 28-inch tall tire would have definitely run into clearance issues.

Fitment

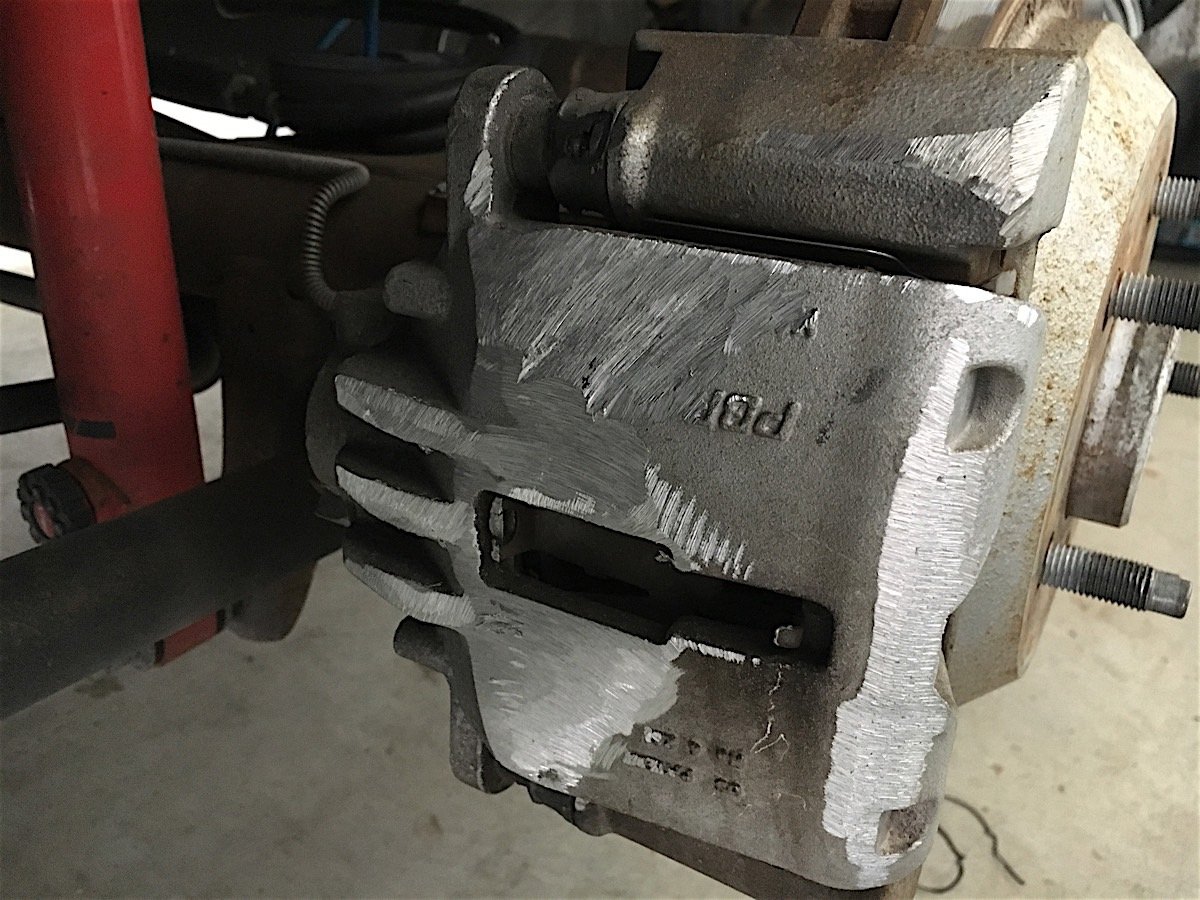

As with any 15 inch wheel on the back of a fourth-gen F-body there are a few fitment issues to address and our car was no different. The barrel of the wheel is just barley too close to the caliper. This required us to take a grinder to the cooling fins in order to give the wheel enough clearance to spin. We just used a standard angle grinder and it only took about 15 minutes to get all the clearance we needed, since the caliper is aluminum and is easy to grind down.

Here you can see where we ground on the calipers to get them to fit. The most important area to focus on is at the back of the caliper towards the inside of the vehicle. The fins and raised rear of the caliper are the most likely to contact. It may take several processes of mounting the wheel and pulling it back off before you get it right.

We simple ground the cooling fins flush with the rest of the caliper. Also, the front of the caliper can occasionally have clearance issues with the spokes as well, which again merely requires a little bit of clearancing. Fortunately for us, we run spacers on the rear of the vehicle to allow the Corvette wheels to fit so this wasn’t an issue for us.

You will want to keep the caliper clearance in mind when you go to balance the wheel as well. Using sticky weights inside the wheel can be tricky as you have to make sure they aren’t interfering with the caliper when they are placed. We had to relocate ours after discovering this once we had mounted the wheels for the first time.

Results

With the tires mounted on the wheels and officially tested fit, we headed off to Auto Club Raceway to see what our new Mickey Thompsons would do for us and to show off these stellar new shoes.

We arrived on a Saturday morning with the car still on its street tires. The Density Altitude (DA) hovered around the 2800-foot mark throughout the day, providing us with decent air. Once we had setup a spot that we could swap the tires over, we headed to the staging lanes to see what the car was capable of on street tires.

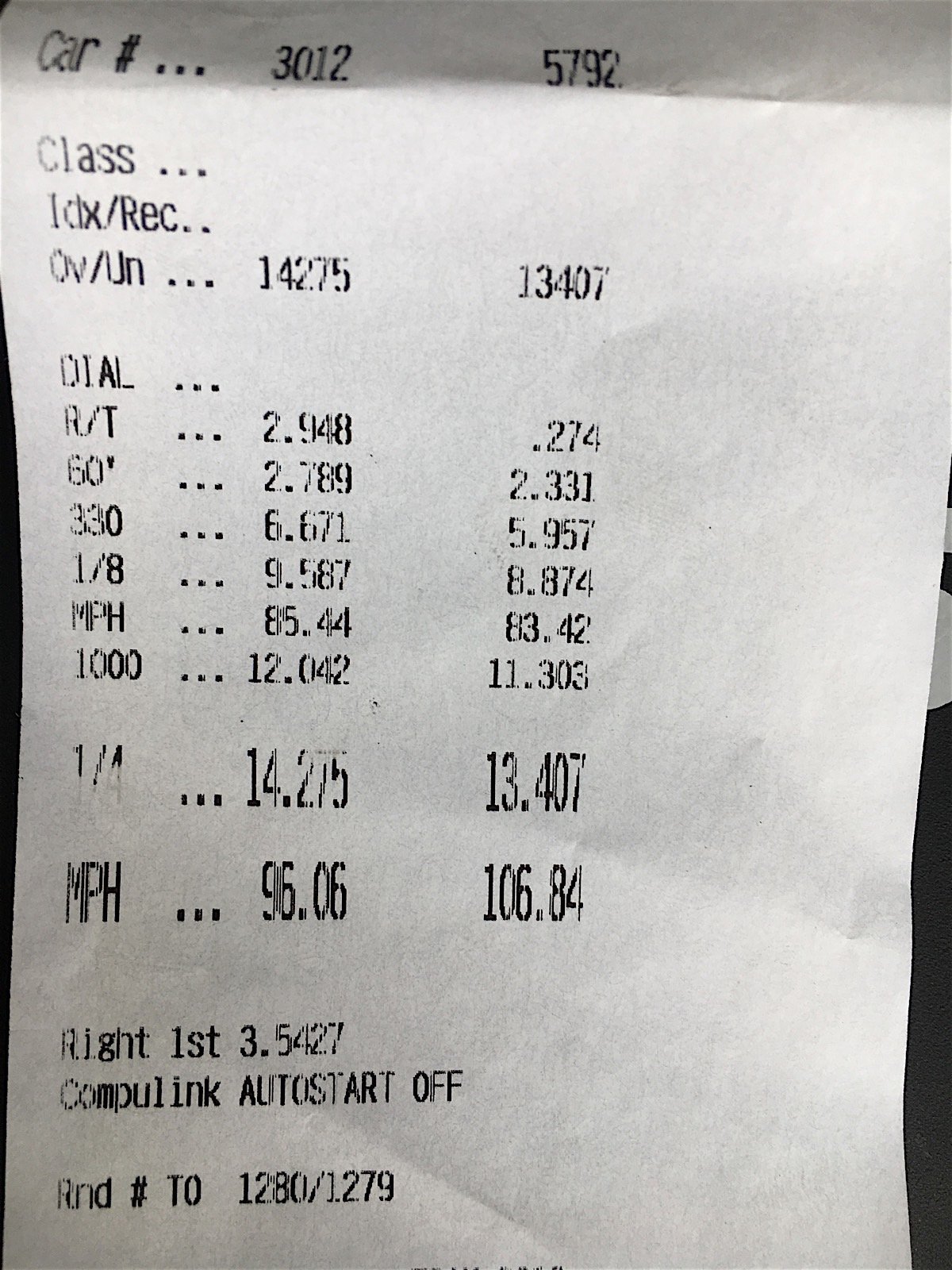

The street tires were kept at 32 psi for all the runs and a small burnout, to clean the tires of any debris, was performed at the outset of each run. After three separate runs, the car’s fastest time on street tires was 13.407 at 106.84 mph with a dismal 2.331 60-foot time. This is about what we expected from the low profile street tires. Coming out of the hole, the car would struggle for traction and then typically spin the tires on the 1-2 upshift. At this point we were sure the car had a lot more in it and would break into the 12s easily.

Next, we swapped the Camaro over to the drag radials and skinnies. We aired the tires down to 15 psi and headed to the staging lanes. After rolling through the water in the burnout box, a decent burnout was done to get the R2 rubber up to temperature.

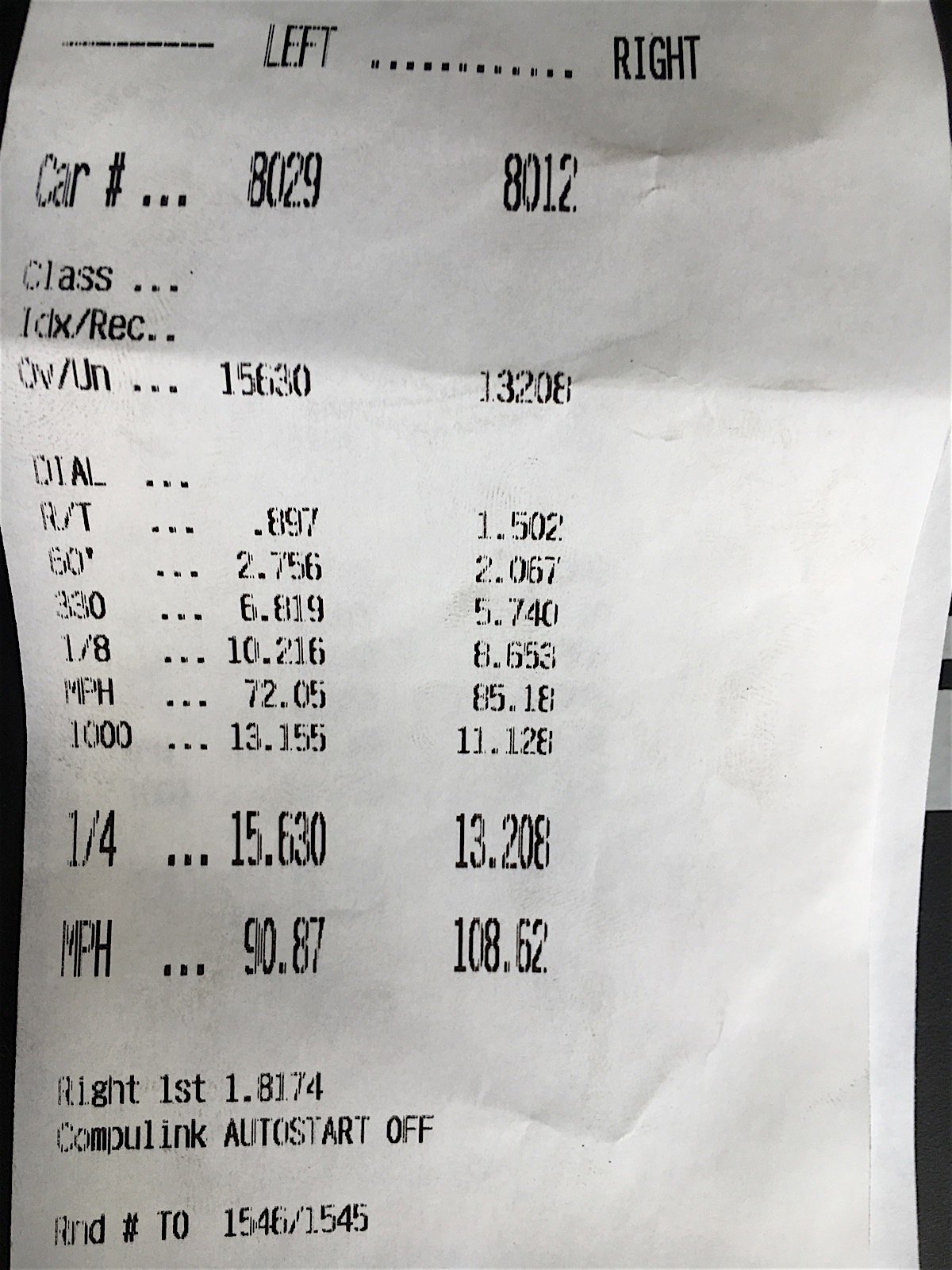

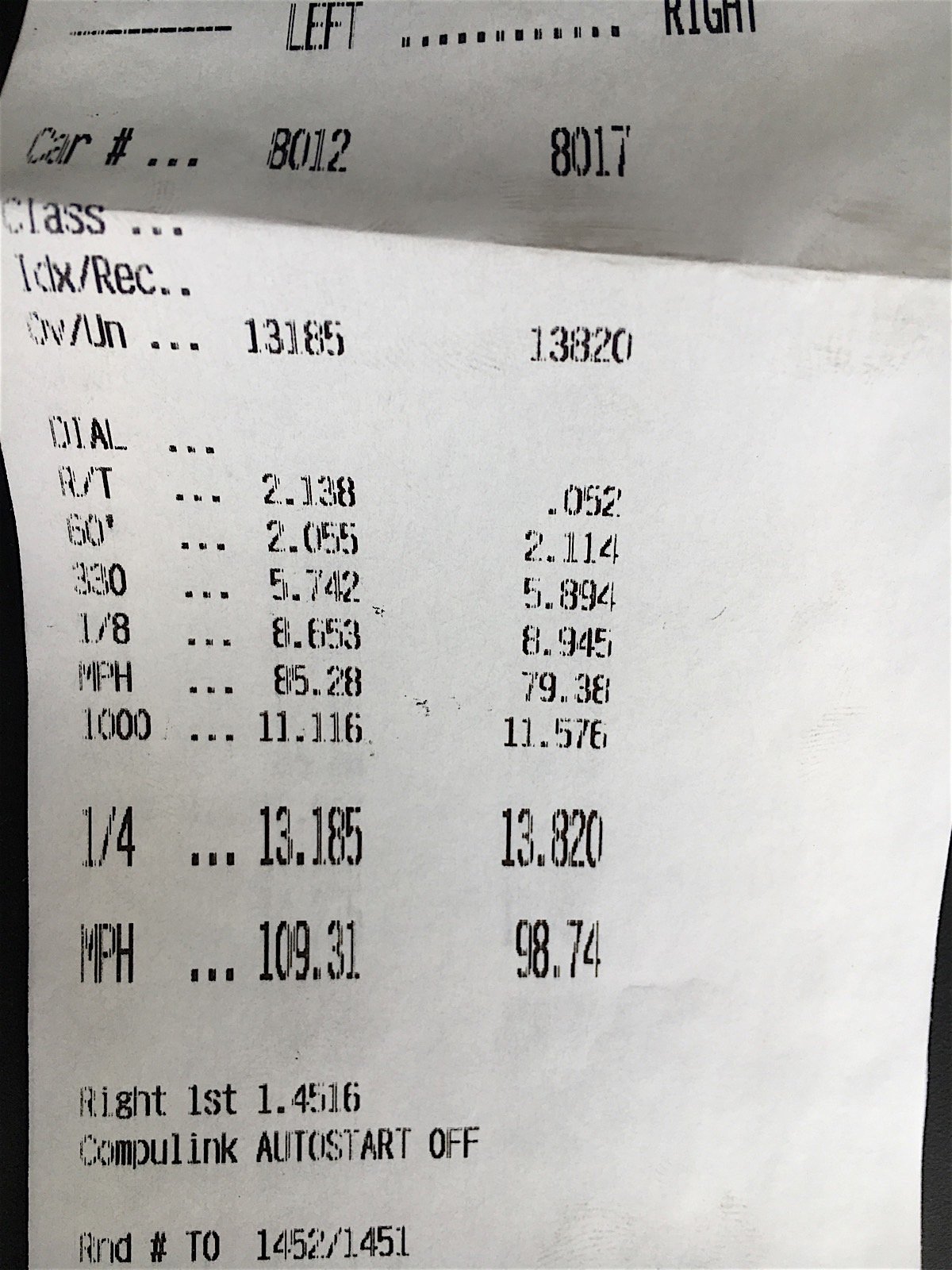

On our first run, we launched the car from around 3,000 rpm—coming off the clutch almost as fast as possible and waiting for it to hook before rolling onto the throttle. This semi-aggressive run resulted in a 13.208 at 108.62 mph with a 2.067 60-foot time. Obviously our numbers improved but we were still sure the car had a lot more in it.

On the next run, after completing the burn out, the driver launched the car at 3,500 rpm while simultaneously rolling on to the gas. This resulted in gut wrench clutch slip as the 106,000 miles stock clutch struggled to pair the power to the planted rear wheels.

At this point, we realized that a new clutch may just been in the cards for our newly acquired fourth-gen, which will be next on our list of mods for this car. And even though the clutch was struggling, we decided to give it one last blast. This resulted in the fastest time of the day, a 13.185 at 109.31 mph with a 2.055 60-foot time.

Conclusion

While we did improve the car’s time, we’re sure that there is more left in this car. Judging by the trap speeds, the car should be capable of mid-12s if not better. However, the clutch is going to have to be dealt with first if we want to see any improvement in our car’s times. But even though we had some mechanical issues, the car still looked amazing at the track and we have established that we have enough traction to overwhelm the stock clutch.

However, as far as the wheels and tires are concerned, they were a home run. We got tons of compliments on the Avengers while we were at the track and the Mickey Thompsons are giving our Camaro as much traction as it can handle–and then some. JMS’ wheels were an easy choice that’s easy on the eyes as well.

Stay tuned as we upgrade the clutch and convert our fourth-gen Camaro to E85 in our next installment. [37]

[37]