We’re in the midst of getting our latest build together, an E85-fed 2002 Camaro SS we’ve dubbed Project Corn Star. At the moment, this fourth-generation F-body isn’t equipped with a flex fuel system, and with the potential for wide fluctuations in E85 concentrations at the pump, we wanted to add a way of keeping tabs on the engine in real time in case we found ourselves with a bad tank of E85 or the concentration was off.

Project Corn Star is due to get a proper introduction any day now. In the meantime, the vital stats here include a 370-cube LS short-block, E85 fueling, Mickey Thompson rubber and a Precision PT7675 Gen II CEA turbocharger. With E85 and boost both in the mix, it’s crucial that we have an accurate real-time monitor of the air/fuel ratio, and one that can actively address any issues that come up is all the better.

Along with the E85 fuel, Project Corn Star is also getting forced induction by way of a Huron Speed turbo kit and Precision PT7675 Gen II CEA turbocharger , so having a method of monitoring the air/fuel ratio has become increasingly vital now that boost has entered the equation in order to avoid causing undue harm to this powerplant.

To that end we’re installing a Failsafe Wideband gauge from AEM Performance Electronics. Not only does the AEM gauge provide the ability to accurately tune AFR, it also features active safety measures. This allows the user to set pre-determined engine operating parameters and if things deviate from the norm, not only will we be aware of it, the gauge will actually trigger functions that will address the issue. Here we’ll go over the features of the gauge and walk you through the installation process.

More Than Just Engine Vitals

For the uninitiated, it might be easy to assume that this wideband gauge just passively displays information back to the user, but AEM’s Flex Fuel Wideband Failsafe gauge goes well beyond simply relaying engine operation data. “A standard wideband controller gauge will typically display in AFR or Lambda and include an output that can be used for closed-loop feedback tuning with a standalone ECU, or at minimum allow AFR to be logged during tuning so that the tuner can review it and make adjustments,” says Lawson Mollica of AEM. “Our Wideband Failsafe gauges for both gas and ethanol fueled vehicles do all of this, but they also include a ground output that can be used to trigger a failsafe strategy if the engine runs too lean or rich.”

The AEM kit comes with everything you need to do the install, including Bosch Wideband UEGO sensor and weld-in bung. Since the gauge is a wideband AFR controller with an internal boost sensor (up to 29 PSIg), it is able to display AFR and either boost or vacuum in real time, and it also includes an on board data logger that records AFR, RPM and boost/vacuum, which can be downloaded and viewed in the AEMdata software.

AEM’s Wideband Failsafe gauge uses software that allows the user to define acceptable AFR at given boost/vacuum levels. If AFR falls outside of a user-defined range, the gauge will trigger the ground output to activate a failsafe, which can pull timing or boost as needed, ensuring we never hurt the engine.

“The failsafe strategy is completely user definable,” Mollica adds. “It can be something as simple as triggering an LED or MIL light, or more sophisticated strategies like triggering a safety or ‘limp’ map in a standalone ECU, opening the wastegate to dump boost, or pulling timing using an aftermarket ignition system that accepts an input.” This ability to constantly monitor AFR at any and every boost level and trigger a failsafe if something goes wrong sets AEM’s Wideband Failsafe and Flex Fuel Wideband Failsafe gauges apart from other currently available wideband controllers and controller gauges.

The Bosch AFR wideband sensor is maintenance-free and never requires free-air calibration, and it also allows you to fine tune AFR from any programmable EMS or piggyback programmer. In terms of engine protection strategies, the gauge's low side output can be used to cut revs, retard timing, trigger a separate fuel or ignition map and activate an ancillary warning light. In turbocharged applications it can also be used to cut boost.

For E85-fed builds like ours, AEM’s Flex Fuel Wideband Failsafe gauge is a particularly useful piece by virtue of the fact that it adds ethanol content to the display, allowing users to monitor three parameters (AFR, boost/vacuum and ethanol content) on one gauge face. “You’re basically getting three gauges in one,” Mollica points out.

The gauge face features 24 three-color LEDs and an OLED display with dimming adjustability. Six different faceplates are included so users can choose the gauge face that works best with the primary function they prefer for the sweeping LEDs, choosing between black faceplates that display AFR, vacuum, boost, Lambda. White faceplates for AFR and vacuum/boost are also included.

“From a safety standpoint, not all E85 is E85, so in addition to displaying the actual ethanol content of fuel, if your ECU does not have the ability to blend maps to compensate for different flex fuel content, then the gauge can protect your engine from damage due to running lean if the actual ethanol content of a fuel is not what was advertised at the pump.”

The Flex Fuel Wideband Failsafe gauge also includes a logging function, which allows the user to look back through event data if the failsafe is triggered and look over the AFR, ethanol content and RPM information to see what the parameters were when the failsafe event was triggered.

“All of our Wideband Failsafe gauges include an internal data logger that logs channels at 30Hz, for an approximate loop logging time of 2.5 hours,” says Mollica.

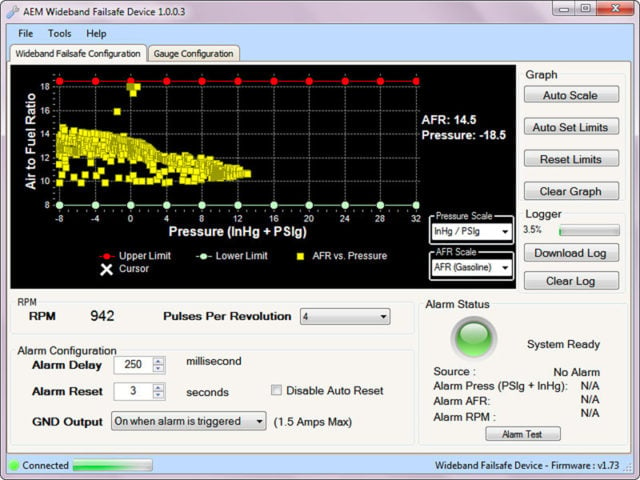

After the engine is tuned and a safe operating window of AFR is established, the gauge continually monitors AFR and boost or vacuum to make sure that AFR does not fall out of the defined operating window at a given boost or vacuum level. If the gauge sees an AFR reading that’s out of range, it will trigger a low side output (ground signal with a 1.5 amp draw max) that can save your engine from serious damage. The Failsafe software shown here can be used to configure the low side output, create a user-adjustable time delay strategy to prevent false alarms, and customize the gauge lighting to alert you if an alarm is triggered.

From a safety standpoint, not all E85 is E85, so in addition to displaying the actual ethanol content of fuel, if your ECU does not have the ability to blend maps to compensate for different flex fuel content, then the gauge can protect your engine from damage due to running lean if the actual ethanol content of a fuel is not what was advertised at the pump. – Lawson Mollica, AEM

“In addition to their engine saving potential, one of the things people really like about these gauges is the ability to monitor multiple channels on one gauge face,” says Mollica. “On the standard (gas) Wideband Failsafe you can monitor both AFR and boost/vacuum, and on the Flex Fuel Wideband Failsafe gauges you can monitor AFR, Ethanol Content and boost/vacuum. You can also change AFR to Lambda and boost/vacuum to BAR if you prefer.”

Given its extensive feature set it’s clear that AEM’s Failsafe Wideband gauges do quite a bit more than just display information back to the driver. For an E85-fueled and boosted car like Project Corn Star, this gauge can not only provide us with essential information about the engine’s health and actively prevent potential damage, it can also help us improve on-track performance not only through tuning but by utilizing the telemetry data it can collect as well, so we headed out to the shop to get this uber-gauge installed in the car post haste.

Installation

Before diving into the installation, AEM recommends connecting the gauge up to a PC through its USB port and heading over to AEM’s download page to check for any applicable firmware updates that might be available for the gauge. Once the gauge is ready to rock ‘n roll with the latest firmware loaded on it, you’re ready to get the gauge install process underway.

We're using an Autometer gauge pod designed for 2 1/16 inch gauges to mount the AEM Wideband Failsafe to the A-pillar. We drilled the holes to attach the A-pillar pod to the stock plastic cover. It attaches using six push pins.

After prepping the new gauge pod and A-pillar mount for it, we drilled the back of the stock panel with a 5/16 inch drill bit in order to create the hole, that we then made larger with a sanding wheel, in the stock panel that will allow the wires and connectors to pass through.

At this point, the wires are threaded through the hole in the A-pillar and snaked through the dashboard. We pulled out the driver’s side AC vent and the headlight switch in order to make this process a little easier.

To help fish the wire through the dash, we took off the driver's side AC vent and headlight switch panel to more access. The center console and shifter boot also needed to be taken out so we could snake the lead for the wideband oxygen sensor through the shifter hole in the center hump. The rubber boot makes sure that the hole is resealed after the wire passes through. Since we know that we will be running other gauges, we wanted to split the power here so we can use one common 12-volt source that can feed the juice to the other gauges. We used a spade connector plugged into the “IGN” port on our fuse block. This port is already open from the factory, and provides the perfect source for key-on voltage that will only draw power from the electrical system when the vehicle is running. The common 12-volt source is attached at the bottom and all of our gauges will feed off the other leads. Ground for the gauges was drilled into the metal bracing under the steering wheel.

The lead for the ethanol content sensor for the gauge has to pass through the firewall, so we had to cut the wires to feed it through a small pre-existing hole in the firewall to feed the wires through and then re-splice the connector back together on the engine bay side. We covered the wires in conduit afterward to clean the engine bay up a bit.

We removed one of the old rear oxygen sensors to make way for our wideband oxygen sensor. We had previously tuned out the rear oxygen sensors, making this the perfect place to mount it since it required no fabrication. However, the ideal situation for a wideband is to be before the catalytic converter, so as to not affect the sensors reading. In this case, we decided to hold off since we will be installing our turbo kit next which has a dedicated bung for the wideband sensor. The quick connector is shown and is fed to the sensor through the shifter boot. To control the activation of the light up function of the gauge, we used a posi-tap to splice into the green wires (shown in the image on far right) to the back of the headlight switch. It provides 12 volts when the headlights are turned on and dims the gauge at night.

After testing the gauge, we moved on to the installation of the ethanol content sensor.

Here we're disconnecting the fuel line and installing the ethanol content sensor. It requires the use of two quick connect -6 AN fittings and an -6 AN coupler. The fuel lines had to be unwrapped in order to give the lines enough space to hook onto the content sensor. We're planning to upgrade the feed line to a fuel rail with an AN line that is shortened in the future.

The failsafe strategy is completely user definable. It can be something as simple as triggering an LED or MIL light, or more sophisticated strategies like triggering a safety or ‘limp’ map in a standalone ECU, opening the wastegate to dump boost, or pulling timing using and aftermarket ignition system that accepts an input. – Lawson Mollica, AEM

Gauge Setup

To program the gauge, we headed back over to AEM’s download page to grab the Wideband Failsafe software we’d need. There are two different software versions depending on whether you’re using a gas Wideband Failsafe or Flex Fuel Wideband Failsafe, so keep that in mind when heading over to the site to make sure you get the right version for your gauge.

“The software is very easy to use regardless of whether you’re using a gas or Flex Fuel Wideband Failsafe,” Mollica says. “There are two tabs: One is for setting the AFR parameters and failsafe strategy including setting alarm delays and reset times. If you aren’t sure how to set your AFR parameters initially we include an auto-set feature that allows you to log your AFR and let the program set the parameters. The second tab is for configuring the gauge face, including what you want to monitor on the center LED and the sweeping LEDs (AFR or Lambda, boost/vacuum or BAR), gauge alarm flash mode and the LED colors of the sweeping LEDs. Once this is done, you simply match your setup with one of the supplied gauge faces and it’s ready to go.”

We set our parameters to a narrow window of air/fuel ratios we would like the engine to stay inside of. For now, we have configured the gauge to flash at us in case the mixture falls outside that range, but when we install the boost controller, the negative output on the gauge will trigger a safety strategy that will cause the boost controller to dump all of the pressure and thus keep the engine safe in the process.

The gauge is a standard 52 mm (2 1/16 inch) size and comes with interchangeable faceplates and bezels that allow you to match up the look with your interior's aesthetic. AFR, boost or vacuum can be displayed on the OLED screen at any given time, while the alarm flash mode gauge’s lighting can also be adjusted to taste.

Looking to add forced induction and/or E85 to your performance equation, or perhaps clean up your interior by a installing a single gauge that’s able to perform the functions of multiple gauges?

Not only can the Wideband Failsafe gauge from AEM Performance Electronics unclutter your setup while adding a number of trick features, it can actively prevent disaster from befalling your engine due to mishaps in the AFR, in turn providing piece of mind that’s well worth the cost of entry.