To auto enthusiasts, Eaton is a household name much in the way Johnson & Johnson is for household items. In fact, both companies have been around longer than most people can remember and produce more products under different brand names than we realize.

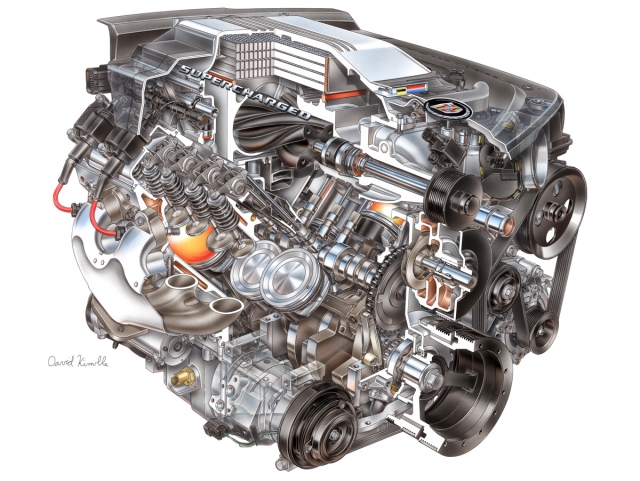

Of course, Eaton’s supercharger arm is perhaps the most high-profile these days, with the company’s Roots-type four-lobe Twin Vortices Series (TVS) design serving as the foundation for factory systems, such as the Corvette ZR1 and Camaro ZL1, as well as the guts for a growing number of aftermarket systems – including Magnuson Supercharger systems and Edelbrock’s E-Force blowers.

On the traction side of things, Eaton is also renowned for a variety of limited-slip and locking differentials, most notably the locking axle employed on millions of GM trucks for the last 40 years. It’s known commonly known by the GM order code for it: the G80. And along with that factory differential, Eaton is also the manufacturer of several differentials that have longstanding reputations in the high-performance aftermarket and racing worlds, including Detroit Locker.

Adding durability alone speaks volumes, it gives you a performance insurance policy not matched by many. – Barney Gwozdz

Additionally, Eaton is one of the top automotive suppliers for countless items built into new vehicles from almost every manufacturer, including valves, lifters, emissions controls, fluid connection products and, well, the list goes on and on. They’re also heavily involved in the heavy truck industry, with transmissions, clutches and more, as well as the aerospace, electrical, and hydraulics industries. With a resumé like that it’s no wonder their testing requirements are so stringent.

We recently got a peek inside Eaton’s expansive proving grounds near Marshall, Michigan, to see how their superchargers and differential systems are put to the test before they’re put on the market. It was a fascinating look behind the curtain at the facilities, methods, and procedures that new products endure before they’re approved for production.

For any self-respecting car nut, it’s a playground matched only by the major auto companies, featuring paved and off-road test tracks, as well as other unique areas designed to test the mettle – and grip – of differentials of all types.

Where It All Began

To be honest, supercharger testing isn’t quite as exciting as the torture tests for differentials, but it’s no less important. Where engineers send G80-equipped trucks through the punishing “Twist Ditch,” the superchargers whir away in dyno cells for hours on end. The bottom line for all of the development, validation, and testing that goes on at the proving ground is it conforms to OEM standards. In other words, whether it’s a component for a Chevy Cruze production car or an aftermarket locking axle for hardcore off-roading, it is put through the same regiment of testing.

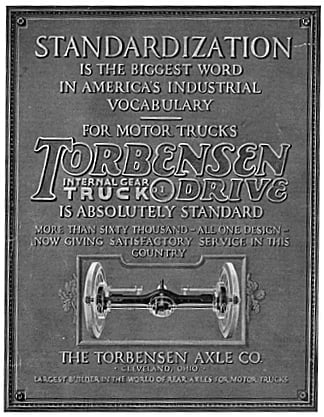

We’ll get into more about all that in a moment, but first a quick history lesson. The groundwork for Eaton was laid in 1900, when inventor Viggo Torbensen developed and patented the first gear-driven axle for a truck. In 1911, he teamed up with businessman Joseph Eaton to form the Torbensen Gear and Axle Company, the precursor to Eaton Corp. The company was purchased by Republic Motor Truck Company in 1917, but Eaton cashed out his shares to form the Eaton Axle Company in 1919.

We’ll get into more about all that in a moment, but first a quick history lesson. The groundwork for Eaton was laid in 1900, when inventor Viggo Torbensen developed and patented the first gear-driven axle for a truck. In 1911, he teamed up with businessman Joseph Eaton to form the Torbensen Gear and Axle Company, the precursor to Eaton Corp. The company was purchased by Republic Motor Truck Company in 1917, but Eaton cashed out his shares to form the Eaton Axle Company in 1919.

He would lead a drive to buy back Torbensen Gear and Axle, too, establishing Eaton as an independent supplier to the growing auto industry. There was a sort-of marriage with Dana Corp. decades ago that led to an amicable divorce. Basically, Dana kept the axle business, while Eaton focused on the differentials. We understand there was a dog involved, too, and the companies continue to share custody – and remain friends.

Eaton officially celebrated its centennial in 2011 and continues to grow, with more than 103,000 employees, located in just about every corner of the globe. Oh, and it’s definitely worth mentioning that the company also holds 11,000 patents. That’s right: eleven-thousand.

On To the Proving Grounds

In November 1969, Eaton officially dedicated their proving ground, on a few hundred acres outside the small, southern Michigan town of Marshall – about 100 miles west of Detroit – to develop as a research and development center.

Sprawling over about 750 acres in Southern Michigan, Eaton’s Proving Grounds includes a 1.6-mile test track, a variety of off-road courses, indoor dyno cells and additional labs. It’s an automotive playground for the serious work of product development and validation.

It now comprises over 750 acres with dedicated testing facilities for superchargers, valves/lifters/valve actuation components, indoor axle testing facilities outdoor “torture tests” and more.

The outdoor test facilities include:

The outdoor test facilities include:

- 1.6-mile paved oval track

- Wooded rally course

- Sand pit

- Twist ditch

- Swamp course

- Log and rock crawling courses

- Hill climbs of 45- and 60-percent grades

- Split-surface 20-percent grade

The Making Of A Locking Legend

Eaton’s popular “G80” mechanical locking differential was born in the early 1970s on GM trucks and has been going strong ever since. Its speed-sensitive, automatically engaging design has evolved over the years, but the basics of its operation and performance haven’t changed. In a nutshell, it performs as an open diff until excessive slip in one wheel causes a flyweight-type governor to open and latch onto a bracket to lock the wheels.

During lockup, a self-energized clutch system causes a cam plate to ramp against a side gear. This ramping action compresses disc packs until both rear axle shafts are spinning at the same speed. The lockup and disengagement processes happen instantly and are virtually imperceptible.

The performance of the G80 was convincingly demonstrated during our visit on the 20-percent split-surface grade, which has a track of rollers on one side. In a test vehicle, we drove up the steep ramp in a vehicle with an open diff and when the primary drive wheel began to spin furiously when it encountered the roller track, forward momentum was effectively halted. After backing down the hill and jumping in a G80-equipped vehicle, we marched up the hill again and the instant the wheel began to spin, the locker kicked in and the truck simply motored to the top of the grade with ease.

A 20-percent grade with a track of rollers provides the perfect demonstration of Eaton’s locking differential, known by its G80 option code in GM trucks. In normal traction conditions, the diff operates like an open unit, but as soon as the drive wheel begins to slip on the rollers, it locks both rear wheels to send the truck up the grade.

It’s here where we should point out the differences between a locking differential and a limited-slip diff, because many people use the term interchangeably and that’s not accurate. With a locking differential, like the G80, the wheels on an axle turn at the same rate, while a limited-slip differential performs exactly as its name implies: It allows the wheels on the axle to turn at different rates, but it can limit the amount of torque channel to the faster-spinning wheel to optimize traction.

Left: The G80 is a speed-sensitive locking differential. At speeds less than 20 mph, it locks both axles when a 100-rpm difference is detected between them. That low-speed activation is important, because the sudden locking of the axles at higher speeds could cause handling or control problems. Right: Along with locking differentials, including Detroit Locker, Eaton also manufacturers some of the most well-known limited-slip diffs, including the Posi and Detroit Truetrac. Eaton originally developed the clutch-style Posi, which was named Positraction by GM in the Sixties and later trademarked as Posi by Eaton. The Detroit Truetrac (shown) is a higher-capacity, helical-gear design.

Eaton took the locking differential into the 21st century with the electronic-locking differential, or “E-locker.” It was introduced originally on the Hummer H2 and is offered on other manufacturers’ vehicles today. There’s an aftermarket retro-fit kit, too, that requires only a couple of wires to hook up.

It may not look very dramatic in this photo, but that hill is a 60-percent grade, which effectively gives the feeling of a nearly vertical climb. The stainless steel track in the center can be watered down to provide a low-traction surface, similar to the roller track on the 20-percent grade.

Eaton is also the parent of the legendary drag-racing differential Detroit Locker. For the limited-slip market, Eaton markets the Detroit Truetrac and the company is also the originator of the famed Posi limited-slip diff. The clutch-type Posi is certainly period-correct for vintage musclecars, but the Truetrac has a higher torque capacity – keep that in mind for your next resto-mod project.

When talking with Eaton Customer Support expert and Technical Specialist Barney Gwozdz, he shared one of the main reasons for such stringent OEM testing on all of their product, “Adding durability alone speaks volumes, it gives you a performance insurance policy not matched by many.”

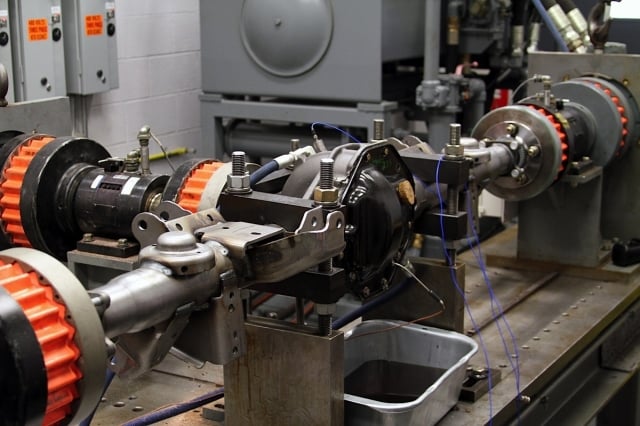

Not all of Eaton’s differential testing occurs on the track. Indoor test cells feature electrically driven axles that work the differentials for days at a time to validate their durability and longevity, with stress tests designed to find their breaking point. Eaton also field-tests its aftermarket components through active participation in a variety of off-roading ventures.

Inside the proving grounds’ dyno cells and test labs, differentials are put to the test on electrically driven axle systems. The testing regimen will often last for days. Electronic monitoring eliminates the need for an engineer to sit with it day in and day out, especially on weekends, but the system automatically sends a notification if a problem arises.

Ya, This Job Blows – Literally

When it comes to the supercharger side of the business, there are no 20-percent grade tests or twist ditches, but plenty of rooms at the proving ground filled with spinning superchargers, blowing their compressed air into the ether of the dynamometer cell – and past more than a few performance-measuring instruments.

Eaton is the company behind the superchargers used on GM vehicles dating back to the supercharged 3800 V-6 and more recently the Corvette ZR1’s LS9, CTS-V and Camaro ZL1’s LSA engines. All are Roots-style positive-displacement air compressors, which deliver a big power boost at lower and mid-range rpm levels. These blowers also come standard with the Roush, Edelbrock, and other aftermarket kits.

Eaton’s jump into the forced induction business came with the 1989 Ford Thunderbird Super Coupe, spreading to manufacturers including Jaguar, Aston Martin and Audi. Of course, Chevrolet is an Eaton champion, too, using the company’s groundbreaking TVS design for the Corvette ZR1’s LS9 and the Camaro ZL1’s LSA engines, respectively.

In fact, the TVS four-lobe, high-helix (the pitch of the rotors) design was developed with the ZR1 in mind. It helps make the most of the supercharger’s capability, promoting greater low-end power and sustaining the boost higher in the rpm band.

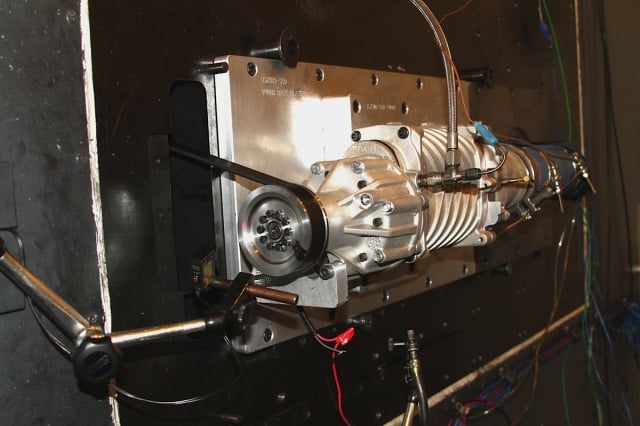

At the proving grounds, this smaller-displacement supercharger is tested with one of Eaton’s drive clutch systems, as the company is continually pushing the boundaries of the technology to find a greater balance of efficiency and on-demand power. They are even experimenting with continuously variable drive systems and enhanced bypass control methods to drive the supercharger only when it’s needed.

Those airflow properties are mapped to the nth degree in the lab, where blowers are run on live engines and electrically driven for independent testing. Durability tests can take 400 hours – more than two weeks – of continuous operation. Believe us, it is quite a sight to walk past room after room, each filled with a high-winding blower that would certainly be more at home on one of our project cars.

Eaton’s superchargers have proven to be bulletproof in OE applications and, as we noted earlier, they’re finding their way into more and more aftermarket systems. On the OE side, Eaton is competing with renewed interest in turbocharging from some manufacturers, but the relative value of their system and increasing efficiency enhancements are sure to make them viable OE power adders for years to come. In fact, Eaton is experimenting with enhanced bypass control methods, drive clutch systems, and even continuously variable drive systems that enable on-demand power delivery with essentially zero off-boost engine drag.

During some supercharger test sessions, a unit will operate for up to 400 hours continuously. The labs literally buzz with multiple blowers spinning away at high rpm and multiple R&D engineers manning the stations and the results.

Indeed, the instant power and torque that comes with a Roots-type supercharger is hard to beat, especially in the low- and mid-rpm ranges. And the general lack of parasitic drag with the design means the engine doesn’t require much power to drive the compressor. That’s a trait Eaton is quick to point out over, say, a screw-type compressor or a centrifugal blower.

During our visit, we saw the tiniest of Eaton blowers that looked suitable for perhaps chain saws, while their largest remains the 2.3-liter TVS compressor used on the LS9 and some aftermarket systems. The folks we spoke with acknowledged that larger-displacement blowers in the aftermarket are something they have to contend with and they’re exploring larger TVS-based compressors. We’ll have to keep our eyes and ears open and keep our fingers crossed on that.

We could have spent weeks at the Eaton Proving Grounds, although our short but informative visit gave us tremendous insight into the serious business of high-performance. Whether it’s the factory G80 diff in your Silverado daily driver or the aftermarket E-Force blower kit you just bolted onto your C6 Corvette, the design and validation methods for each is reassuringly the same. It’s also encouraging to know this level of quality and expertise is still developed right here in the USA.