Interesting innovations with nitrous oxide that focus on precision control as well as more “juice” may soon percolate upward from the popular X275 classes to more powerful cars, including Pro Mod.

Interesting innovations with nitrous oxide that focus on precision control as well as more “juice” may soon percolate upward from the popular X275 classes to more powerful cars, including Pro Mod.

“Honestly, I think there’s further room for development based on some of the things we do with these small-tire cars,” says Steve Johnson, owner of Induction Solutions where some of the quickest X275 nitrous setups are developed. “Based on the amount we put through those systems and how effective the progressive controllers work.”

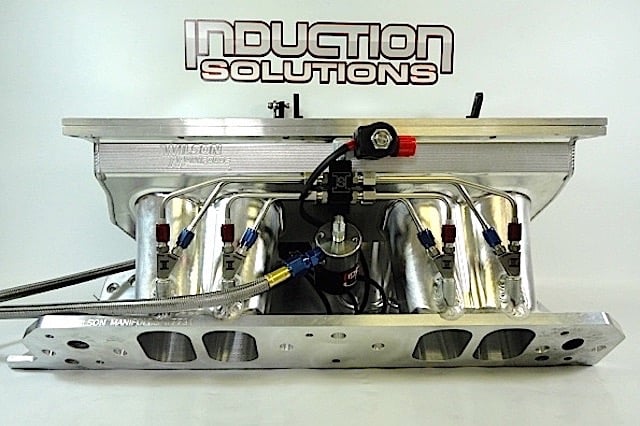

Here’s a single-stage nitrous system designed by Induction Solutions for Ron Rhodes’ champion X275 car. Note water injection behind the direct-port nozzles. (Photo by Mike Galimi)

Driven by rules that allow only a single stage of nitrous, engine builders are working with nitrous suppliers to not only get more nitrous into the cylinders, but also manage it properly and finesse the tune to take full advantage of all the extra oxygen.

We’ve proven you don’t need as much fuel. – Steve Johnson, Induction Solutions

“The best thing I ever did to my car was go to one system,” confirms Ron Rhodes, builder and driver of one of the top X275 cars in the country who uses an Induction Solutions-designed single-stage system. “I used to have two systems with timers. The car was fast but the best thing I ever did was put it all on one system.”

Get The Tune Right

Nitrous developers are moving to larger solenoids and designing nozzles with less back pressure to allow more “squeeze” into the intake. Also, better fuels designed for nitrous engines are available.

Nitrous Oxide Nicknames

- Bottle – “On the bottle” refers to using nitrous. Also applies to “on the jug.”

- Button – Nitrous system can be activated with a button switch on the gear knob or steering wheel, so if your car is “on the button” it’s running nitrous. Term is outdated as most racers use WOT switches and timers to activate nitrous.

- Doped – In some regions of the country, if your car is “doped,” it means it has a hidden nitrous system.

- Juice – Street lingo in the vein of “juicing up” the engine.

- Laughing gas – More associated with dentist’s office where medical-grade nitrous-oxide is used as a anesthetic. That’s why automotive nitrous usually has a touch of sulfur dioxide to discourage human consumption.

- Nitro – Completely incorrect slang for nitrous oxide.

- NOS – Often pronounced “nawz” from the “Fast and Furious” movies, it’s the trademark name for Nitrous Oxide Systems, a performance aftermarket company that sells nitrous systems; the name is also used for an energy drink. Not to be confused with N.O.S., which stands for New Old Stock.

- NOX – Acronym for nitrogen and oxygen.

- Spray – Refers to the nozzles that spray nitrous into the manifold.

- Squeeze – A play on the fact that nitrous-oxide squeezes more fuel and oxygen into the cylinder.

There are numerous factors involved, including engine design, type of fuel and especially the weather, are considered when balancing the nitrous-fuel delivery with ignition timing. But conventional wisdom that professes generous fuel amounts is being challenged lately, especially for racers.

“We’ve proven you don’t need as much fuel,” says Johnson, pointing to out-of-the-box systems with excessive baseline setups. “We closely monitor nitrous-to-fuel ratio when we flow systems, and we’ve continued to lean it out to get the most efficient burn rate. You want power with no excess fuel.”

Johnson recalls that in the early days of nitrous plate kits, it was routine for the fuel jet to be larger than the nitrous jet.

“For our plate kit, it’s not uncommon for our nitrous jet to be anywhere from 10 to 35 numbers bigger than the fuel jet,” says Johnson.

But then a nitrous system can reach a diminishing point of return, depending on the engine and conditions. Remember, a nitrous engine is still basically naturally aspirated. The engine needs a pressure differential between the intake manifold and cylinder, and atmospheric pressure remains the critical factor in filling up that cylinder. At some point there’s an impasse or equilibrium, and more nitrous simply doesn’t matter. That’s when other factors such as cylinder head design and cam timing need improvement to take advantage of additional nitrous oxide’s full capability.

Nitrous always looks great on a billet intake, like this one from Wilson Manifolds with increased cross-section runners and larger plenums can take advantage of the benefits nitrous offers.

Nitrous 101

To quickly review, nitrous oxide is not a fuel but rather an oxygen-bearing molecule. It comprises two nitrogen atoms with one atom of oxygen, or N2O. By weight, nitrous is about 36 percent oxygen, which is denser than the mix of oxygen in the atmosphere, which in dry air, is about 21 percent. Normally nitrous oxide is in a gaseous state, but when compressed to around 800 to 900 psi it converts to a liquid – which is how it’s stored in traditional 10- or 15-pound nitrous bottles.

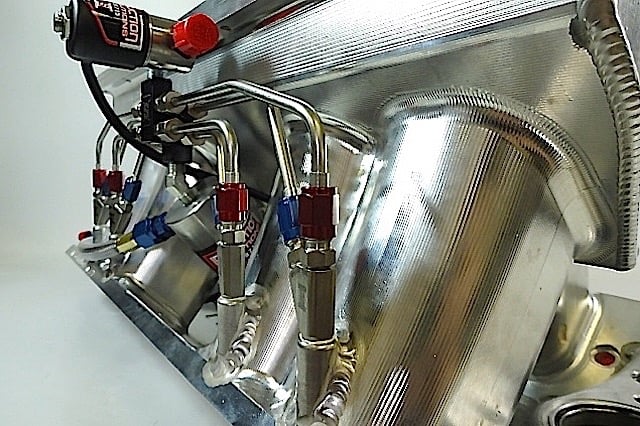

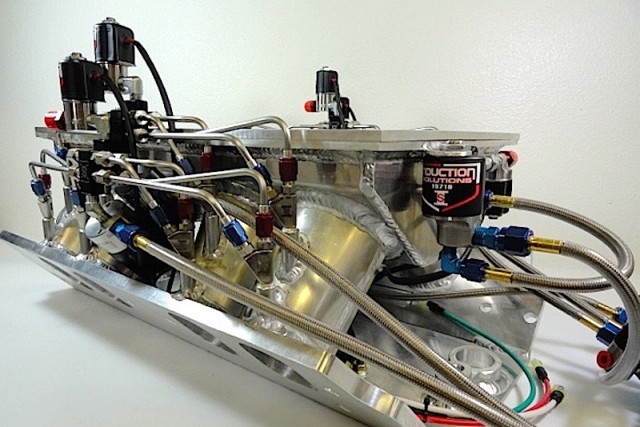

Unobstructed view of another IS direct-port design. The larger solenoid on the bottom controls the nitrous which uses blue fittings on the nozzles. The smaller solenoid on top controls the fuel, which leads to the red fittings.

The magic happens when nitrous is released into the atmosphere, or in the case of an automotive engine, the intake manifold. It suddenly supercools, which makes for a very cold, dense air charge. In fact, by the time you do the math, a nitrous blast provides around 2.3 times more oxygen than a comparable amount of ambient air it will be displacing in the intake system — which is the kind of tradeoff racers love to embrace. The oxygen atom is still attached to its nitrogen partners at this time but will separate as the combustion process begins and cylinder temperature increases; thereby, allowing the oxygen to participate in the full combustion process with the fuel.

Shown is an example of a 3-stage system with two sets of nozzles for each intake runner and a spray-bar system in the intake plenum.

The catch, of course, is adding just the correct amount of fuel to maintain the desired air-fuel ratio. The right balance results in increased cylinder pressure and more power. Too much fuel, or a rich condition, reduces power somewhat because the unburned mixture absorbs valuable combustion heat and energy that could drive this piston.

Too little fuel, or a lean condition, means that the combustion temperatures could soar beyond ideal, leading to detonation – which then leads to very high localized temperatures that, when mixed with another incoming dose of oxygen, results in burning metal. A testament to this dynamic can be found in the corner of every aggressive nitrous racer’s garage in the form of a box of burned pistons and valves.

“Since we flow all the systems, we know the nitrous-to-fuel ratios,” says Johnson. “The biggest variable in making the tune is the right amount of engine timing.”

As engines are built to accept more nitrous, solenoids have gotten bigger. Notice the larger orifice on the left. The left solenoid is also a new design that includes a PTFE-pinned plunger, which is more efficient than older black RTM self-compensating plunger.

The nitrogen can impede the combustion process slightly — that is, act like a buffer before the oxygen molecule breaks free and helps the fuel burn. However, even with this buffer the burn rate for a nitrous-enhanced combustion is much faster than a straight normally aspirated engine. Therefore the ignition timing must be pulled back, depending on the amount of nitrous introduced to the engine, but still be enough to ensure a complete burn.

No Rules For Pulling Timing

“I always try to help customers choose their ignition timing numbers,” says Johnson. “Based on all the different cylinder head designs you can’t always use the ‘two for 50’ rule.”

Johnson is referring to the time-honored formula of pulling two degrees of timing for every 50 horsepower that a nitrous system adds to the engine. Nitrous companies generally offer two types of systems or kits, and with each they will rate the amount of horsepower that system can add to the engine under the right conditions. These ratings can range anywhere from 100 to 500 for production kits while custom nitrous systems can add more than 1,500 horsepower.

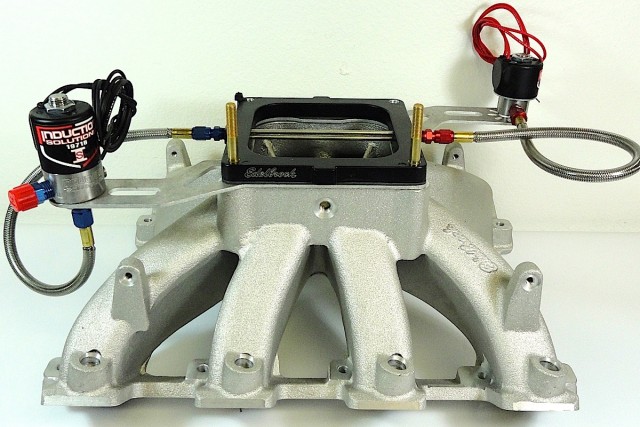

Shown is a plate system from Induction Solutions. Note the two spray bars that go across the plenum opening. One is for nitrous, the other for fuel.

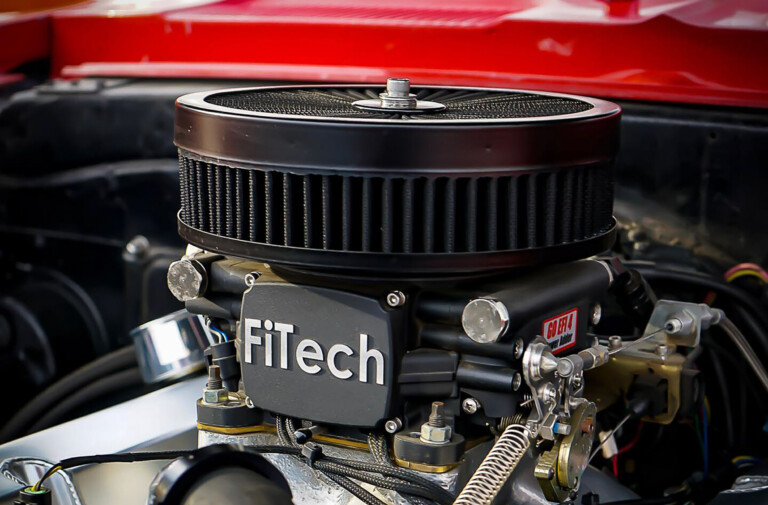

The basic system consists of a plate that fits between the carburetor and intake manifold. This plate supports two spray bars — one for nitrous and one for fuel. Each is plumbed to a solenoid that is basically an on-off valve to deliver the nitrous or fuel to the respective spray bar. The amount of fuel and nitrous can be adjusted with different sized orifices or jets that regulate the flow into the spray bars. Sometimes a plate system will have four spray bars, two each for the fuel and nitrous.

A more efficient and powerful system called direct-port nitrous places individual nozzles that blend and atomize the nitrous and fuel, then introduces that mixture directly into each intake port. Again, solenoids are used to feed the nitrous or fuel to the nozzles, which control the flow with jets at each inlet. This basic arrangement is called a single-stage system. When two complete sets of nozzles, or two for each cylinder, are mounted on the intake manifold, then it’s a two-stage system. Some engines have four stages of nitrous. In fact, Johnson says those four stages can be split from bank to bank, effectively creating eight stages—each with their own timer.

Some racing classes restrict the engine to a plate system, and others allow only a single stage of direct port.

Here's a couple of non-traditional setups. On the left, the nitrous lines are routed under the intake plenum. This cleans up the top side of the engine and doesn't crowd the fuel injectors. On the right, the solenoids are mounted in front and rear of the intake and split lines to each bank of cylinders.

“In a single stage direct port, if we really wanted to push the limit, we could put 800 or 900 horsepower through it,” says Johnson. “Our top plate will move about 600 real horsepower.”

With almost any nitrous setup, the full amount of juice can’t be dumped into the engine on the launch. The tires simply can’t hold that much of a power jolt. In earlier days, timers would turn on the solenoids at a predetermined time after the launch and after the tires had a chance to hook up. Or if it’s a multi-stage system, one would come on at the start and the others would follow at pre-determined times, depending on track conditions.

Managing The Timing With The Progression

Progressive controllers now manipulate the solenoids to add nitrous in a more linear curve. The solenoids are still open or closed but can now be modulated to the tuner’s wishes. Combined with ignition timing adjustment, a nitrous engine can be tuned more precisely to maximize traction and track conditions.

Here are two models of nitrous controllers: Edelbrock on the left and NLR on the right.

“One of the big keys to a large single-stage system is how you manage the ignition timing with the progression,” says Johnson, who recommends progressive nitrous controllers from Edelbrock and NLR. “You can’t drop all the timing out at one time, as the engine will fall on its face and can’t recover.

Here’s a shot of Scotty G’s 6-stage “dry” manifold, meaning all the lines to the nozzles carry nitrous. The fuel is added through the fuel injection system mounted on the underside of the runners. Four stages are shown on the runners while the other two are inside the plenum. Note the jet size reminders.

“And one of the biggest misconceptions about a progressive controller is thinking the percentages dialed in is the percentage of horsepower,” continues Johnson. “It’s only a percentage of the duty cycle. The controller doesn’t know what it’s hooked to or how big a jet you have in it. You can’t take a 100 horsepower jetting, set the controller at 20 percent and truly have 20 percent compared to taking a 1,000-horsepower system and setting that same controller at 20 percent.”

“Honestly, I’d be lost without a controller,” adds Rhodes. “There’s definitely a learning curve, but there’s a lot to work with. Slowly applying the power is the key with these small tires and hot track temperatures.”

Rhodes has developed four basic tunes that cover most conditions he faces at tracks around the country, and he says the NLR controller he uses is very repeatable for consistency.

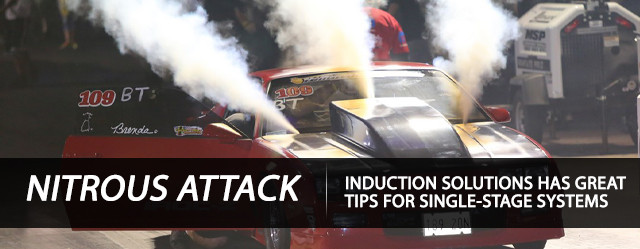

Purging the nitrous lines is not only a crowd-pleasing act of showmanship but is necessary to ensure there are no bubbles and only liquid nitrous going to the solenoids. On the left is Brenda Paddock, who runs an Induction Solutions 3-stage system, and Ron Rhodes' Camaro is on the right.

“You do have to make the power match the track,” says Rhodes, who has raced his Camaro since 1986. “Whenever I adjust the progressive, I adjust the chassis, as well.”

Here’s another view of an Induction Solutions manifold with stages mounted on both the runners and inside the plenum.

Rhodes has run a best of 4.46 at 154.99 mph in testing over the 1/8-mile. In competition his best is 4.52 at 154.00 mph, and he’s also recorded a blistering 1.03 60-foot time. Last year Rhodes dominated No Mercy V by qualifying No. 1 in both the Leaf Spring and X275 classes and reaching the finals in both. He won Leaf Spring but just missed in X275.

The beauty of Rhodes’ achievements lies in the simplicity of the BES Racing-built 460ci small-block he runs. It’s based on a Dart raised-cam, tall-deck Iron Eagle block fitted with a Callies crank, GRP rods and Ross Pistons. There’s also a Comp Cams solid roller, Moroso oil pan and Peterson external oil pump. Nothing exotic about the 23-degree raised-runner All Pro 245 cylinder heads, other than they were totally hogged out by Tony Bischoff’s crew at BES. On top is a Dart intake manifold that was prepped with the nitrous and water-injection setups by Induction Solutions. The Dominator carb is from CFM Performance.

“The water injection helps the tuning window, especially when the air is super dry,” explains Rhodes. “I watch the water grains and humidity closely because they play a real big factor.”

Importance Of Nozzle Design

The nitrous system is also rather uncomplicated with a -8 AN line bringing fuel and nitrous to a pair of Y-blocks that break off into two -4 AN lines. They join up with .125 bottom-feeder solenoids that are hard-lined to the IS nozzles, which are more sophisticated than first meets the eye.

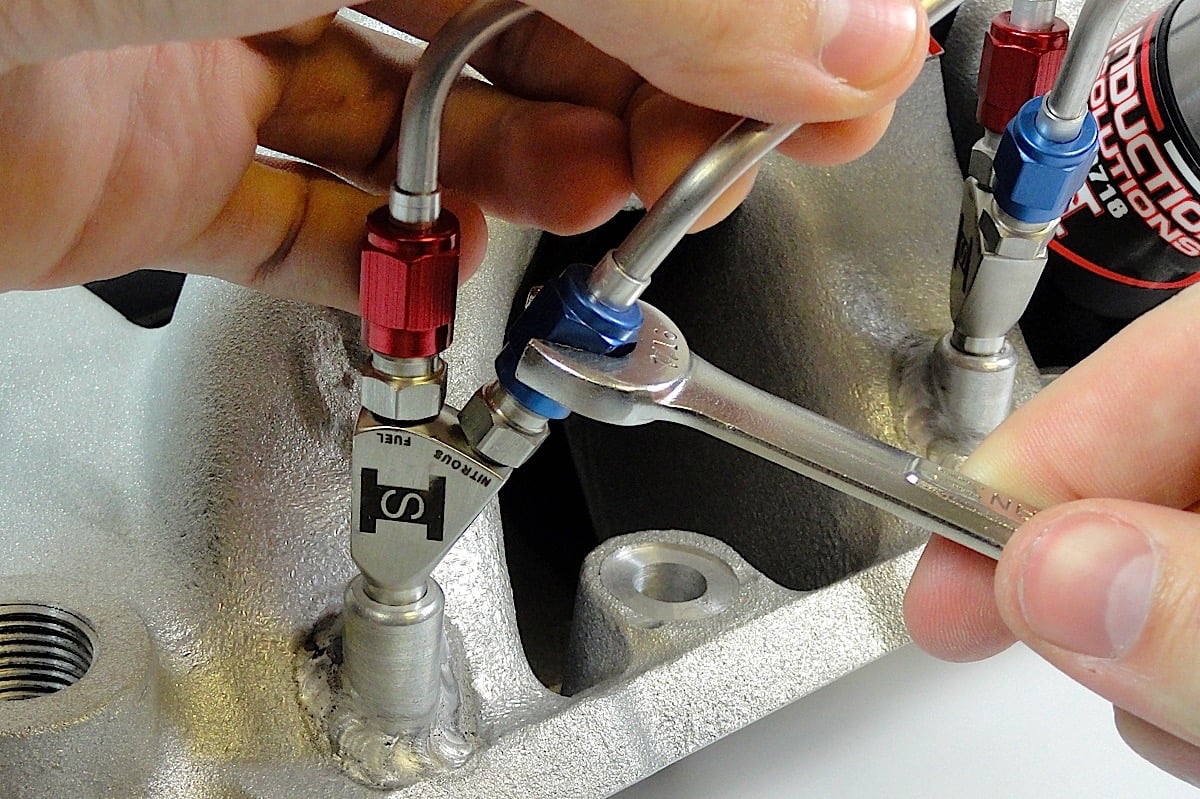

“Nozzle design involves many factors, not just moving large amounts of nitrous,” explains Johnson. “There’s the consistency of how it sprays and atomizes the mix. Also, we’re cautious of how the nozzle can potentially signal the fuel side. Some nozzles can create a backpressure and slow down the fuel, when compared to others, or they can create a vacuum and pull more fuel.”

Nozzle design and choice is critical to optimize performance in a nitrous engine. Induction solutions offers four different types of nozzles. From left, dry annular nozzle, annular nozzle, 90-degree nozzle and and dry 90-degree nozzle. All IS nozzles have compact bodies constructed of stainless steel. A dry nozzle means that only nitrous is injected through it and the extra fuel delivery is handled by the EFI system.

Tuning for nitrous requires a little stricter attention to the engine’s symptoms and performance, as well as checking a couple readings that might not have been typically monitored before.

“Obviously, the spark plug is the most important thing to look at, then look at the data logger,” suggests Johnson. “A lot of people don’t think about it, but we look at crankcase vacuum during the run. We’re evacuating the crankcase and controlling the oil, but what happens with a nitrous car, if you upset it and detonate, the rings flutter. When you flutter the ring you leak compression and you’ll see vacuum fall off.”

Important considerations for nitrous designs are location of the nozzles for the most efficient spray without interfering with the airflow, and size of the jets that determine the horsepower level of the system.

Designing a nitrous system for a race engine takes into consideration all the critical factors such as vehicle weight, tire size, displacement, compression ratio, cam timing, type of fuel, induction choices, ignition and fuel delivery controls as well as proposed racing venues. Rules may dictate certain designs for specific applications but Induction Solutions can plumb a nitrous system into just about any powerplant, whether it calls for a plate or direct-port system or a multi-stage setup. Beyond the system design, Induction Solutions is also eager to provide tuning advice as needed.

“We’re fairly unique as that’s part of our tech support,” sums up Johnson. “I provide a tech sheet with each system and then make myself available when they go to the track.”