Perhaps no factory horsepower-building solution has been more well-received among performance enthusiasts than supercharging; over the last decade-and-a-half the OE manufacturers have turned towards the supercharger as a means to build what is potentially the best-performing group of cars the world has ever seen. From the Corvette Z06 to the Shelby GT500 Mustang, the supercharger has seen a renaissance among the manufacturers to create vehicles producing well in excess of 600 horsepower right off the showroom floor.

It’s a far cry going from the big-block Chevelles and HEMI Mopars of years past that sucked down fuel at an alarming rate, to move to engines that are two-thirds the displacement but still achieve 20-plus miles per gallon on the highway and produce substantially more horsepower. It’s all thanks to the wondrous piece of automotive engineering known as the supercharger.

The factory supercars rely on these pieces to build their immense horsepower levels, and as reliability has improved, we see the same technology showing up in the aftermarket, specifically through the use of Eaton Corporation’s Twin Vortices Series (TVS) supercharger rotor packs, which are an advancement over the company’s earlier M-series superchargers. The TVS debuted in Australia in the Toyota Racing Development Aurion, then came back home to the US at the 2007 SEMA Show, where it appeared on a ROUSH Mustang, and subsequently found a home in OE applications in the 2009 Corvette ZR1 and Cadillac CTS-V.

Today we have an assortment of information for you regarding the companies making use of the technology in their own, internally-designed products that take the TVS from bare rotor packs to complete superchargers. Before we get ahead of ourselves, let’s discuss that technology.

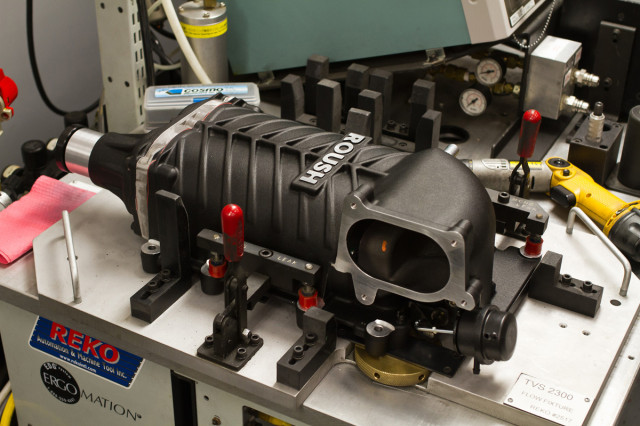

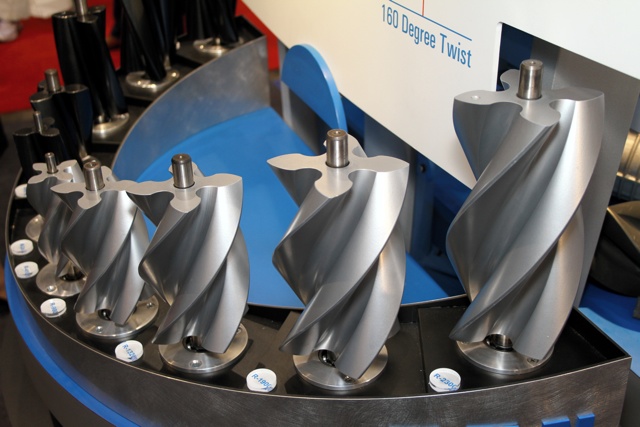

Here’s a shot of the TVS rotor pack. There are a pair of rotors that interlock, with lobes that have been twisted 160 degrees. Air is sucked into the rotor pack, then forced into the engine. Some TVS superchargers fire downward through an intercooler into the engine, others fire upward into the manifold and then into the engine – it all depends on the manufacturer’s design.

How It Works

The original Eaton supercharger found under the hood of older vehicles like the Ford F-150 Lightning, 2003-’04 Cobra, and others used a trio of lobes with a 60-degree twist; while these were capable of adding substantial power, current-day engineering techniques and methodology resulted in the Twin Vortices Series blowers.

The TVS design is patented and uses a pair of four-lobe rotors that have been twisted 160 degrees to give them a higher helix angle. The new design allows the supercharger to provide more efficient airflow into the engine along with improved noise and vibration reduction characteristics. In addition, the design allows for a smaller package size that allows the supercharger to fit neatly under today’s aerodynamic hoodlines. It is used today on the GM LSA, LS9, and LT4 engines – check out the sidebar for more information.

The TVS fits a variety of applications and comes in numerous displacements that can be tailored to the specific vehicle application to provide more power and better fuel economy from an engine that wouldn’t otherwise be capable of such performance.

Different displacements of the TVS Technology on display, culminating in the big-dog 2.3-liter that’s used in many performance applications today. Only one rotor from each pack is shown here.

The TVS in OE Applications

General Motors began using the TVS-style supercharger on the 2009 Cadillac CTS-V, where the 6.2L LSA engine debuted with a whopping 556 horsepower and 551 foot-pounds of torque – Cadillac’s most powerful engine ever offered. The LSA uses the 1.9-liter TVS supercharger on top with a 9.0:1 compression ratio to achieve these numbers.

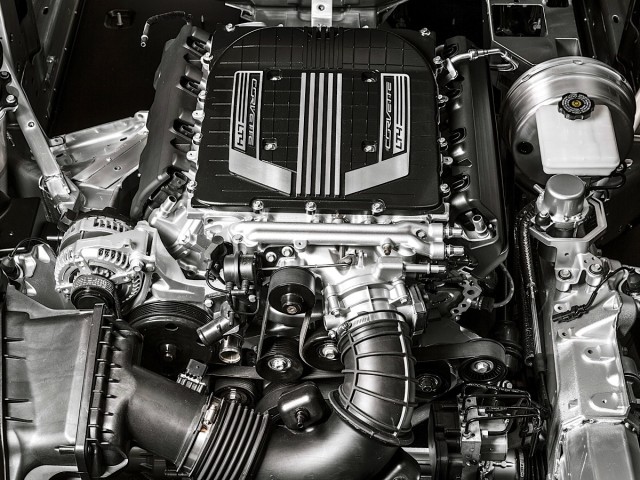

The LS9 in the 2009-13 Corvette ZR1 is similar to the LSA in that it has the same 6.2L of engine displacement, but uses the larger 2.3-liter TVS supercharger to top out at 638 horsepower and 604 foot-pounds of torque. The top dog in GM’s arsenal is the brand new LT4 engine found in the 2015 Corvette Z06 (pictured) that has the 2.3-liter TVS on top; it spins the dyno to 650 horsepower at 6,400 RPM and 650 foot-pounds of torque at a low 3,600 RPM – a hallmark of the low-end grunt that the TVS superchargers are known for producing.

“The original TVS supercharger rotating groups were released into the aftermarket shortly after they were introduced to OEMs,” says Eaton’s Grant Terry. “In fact, the first production vehicle to use TVS technology was a program led by our Australia distributor, Harrop Engineering. This was on a 2009 Toyota TRD Aurion using the R1320 rotor set.”

ROUSH Performance, Edelbrock, Street Legal Performance, Magnuson, and VMP Tuning have taken the TVS technology and run with it, creating systems for everything from Jeeps, to Mustangs, to Camaros and Corvettes, providing the same reliability and durability expected from an OE application in the process.

“Our distributors are fully trained to build superchargers to Eaton’s production specification. We teach them how to machine housings, covers, and other parts, and supply them with all the necessary production-validated components like seals, bearings, fasteners, and shafts that they need to build a full supercharger to Eaton’s production specifications. Where necessary, on specific projects, we will support with engineering assistance. We have regular communication with all of our distributors,” Terry explains.

As the rotor pack and gearset is the only portion of the product sourced from Eaton for each of these companies, they all make their own proprietary supporting equipment for each application, and each company has a different vision for what they are trying to provide the consumer, as you’re about to find out…

ROUSH Performance

The gang at ROUSH Performance has been modifying vehicles for years – their lineup of Mustangs, F-150’s, and SVT Raptor vehicles takes what’s already an outstanding factory platform and applies the ROUSH touch to build an even better mousetrap.

During the engineering process on those vehicles, the company develops the parts that are used on the ROUSH assembly line; perhaps most importantly, their superchargers that are based on the 2.3-liter Eaton TVS rotor pack. The company currently has kits for each of the above-mentioned vehicles that offer a number of different power levels to allow the prospective owner to pick the kit that best suits their needs. Interestingly, they don’t vary compressor size by vehicle – they’ve found that the 2.3 is flexible enough to work for each platform where a ROUSH supercharger system is offered.

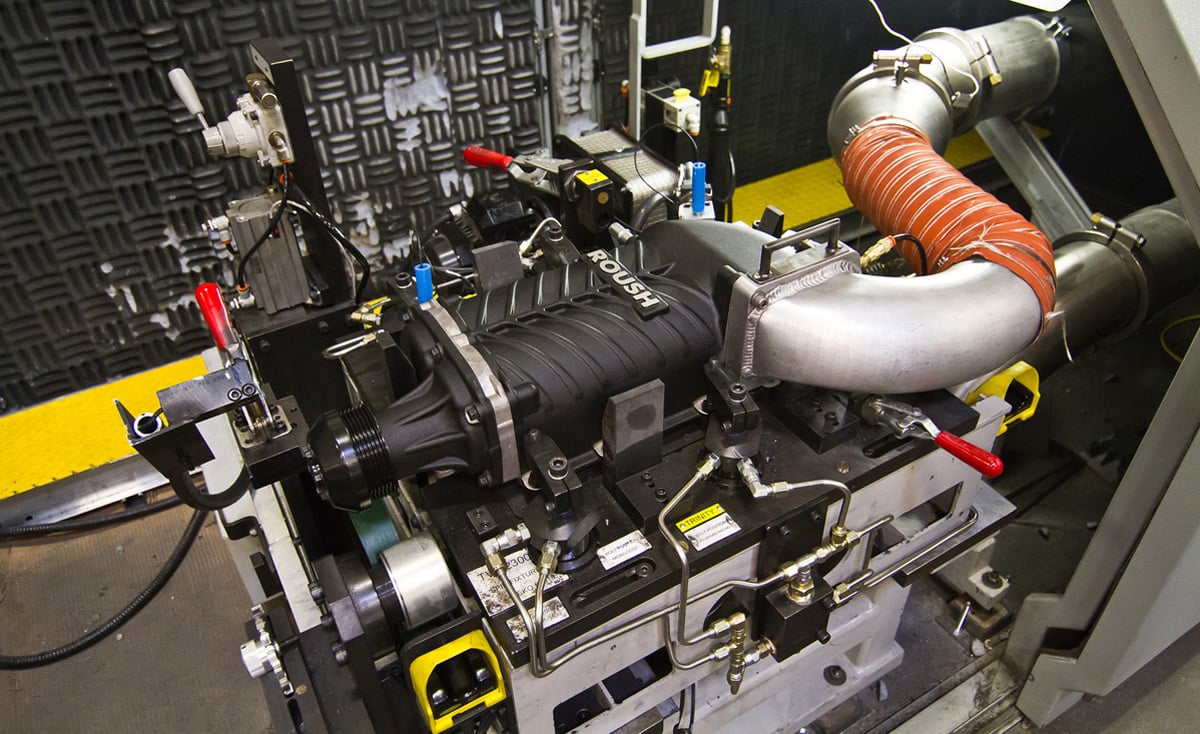

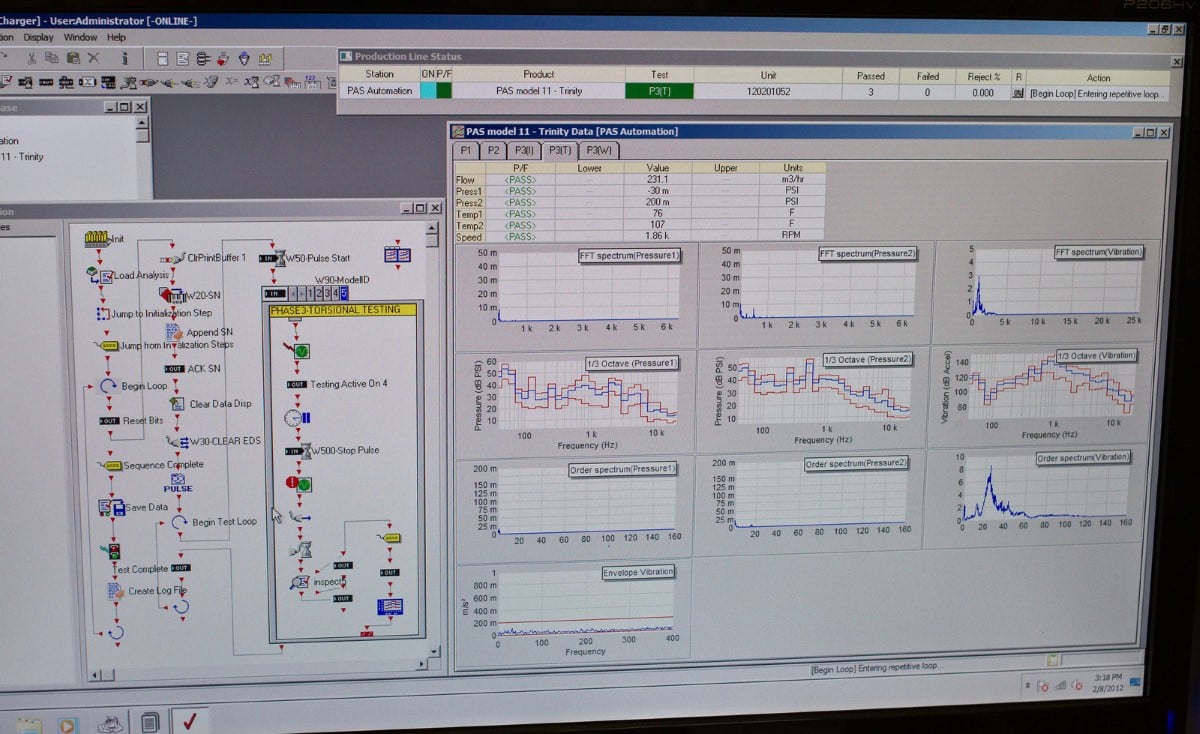

ROUSH expends substantial resources to test and validate the performance of their supercharger systems. Various parameters are monitored in an effort to provide a supercharger system that doesn't alter drivability, and in fact enhances it.

The strategy behind the ROUSH supercharger systems – regardless of vehicle – is simple. “We really want to make sure that our systems offer an OE fit-and-finish. It has to look, feel, and drive equivalent to the base vehicle is not better. The big thing for us is the little details to go into the creation of the kits from a drivability standpoint,” says ROUSH’s Jay Velthoven.

“We test in hot weather scenarios at our test facility in Nevada. We want to make sure the durability cycles can withstand the heat. On the flip side, we also have a facility in Bemidji, Minnesota, where we do our cold-weather testing. We make sure that the package works far beyond the environment where the kit is developed, as they are tested in temperatures ranging from -20 degrees up to 120 degrees Fahrenheit and all the way up to 14,000 feet of elevation.”

ROUSH offers TVS Phase 3 kits for the 2011-’14 Coyote engine that pumps out a solid 675 horsepower – an increase of 255 horsepower and 208 foot-pounds of torque over stock. The kits are delivered in complete form, including all fueling components, new upper and lower intake manifolds, a twin 60mm throttle body, and new full-face low temperature radiator. All required fasteners, hoses, brackets, wiring and clamps are also included for a true bolt-on proposition. The supercharger system also comes in Phase 2 (625 HP) and Phase 1 (575 HP) configurations for the current Mustang platform. Many of the systems come with a 3 year/36,000 mile warranty and are the same pieces installed on the ROUSH vehicles.

The company’s F-150 supercharger systems follow similar principles, regardless of 5.0L, 6.2L, or Raptor applications. Up to 590 horsepower is possible from the 6.2L F-150/Raptor, with 570 horsepower available for the 5.0L – huge increases that are guaranteed to get the blood pumping when you hammer the loud pedal.

“We have to make sure that with our systems, the vehicle’s always going to drive the same, it’s always going to start, and idle properly. I know that we’re the only supercharger system manufacturer that goes to the extent we do to ensure that the vehicle drives like stock with our supercharger kits installed; part of that is because we build our vehicle line. Every time we alter these vehicles, we become the manufacturer of record, and because of that we inherit the liability and have to take the same approach that the OE’s do on making sure that the vehicles are reliable,” says Velthoven.

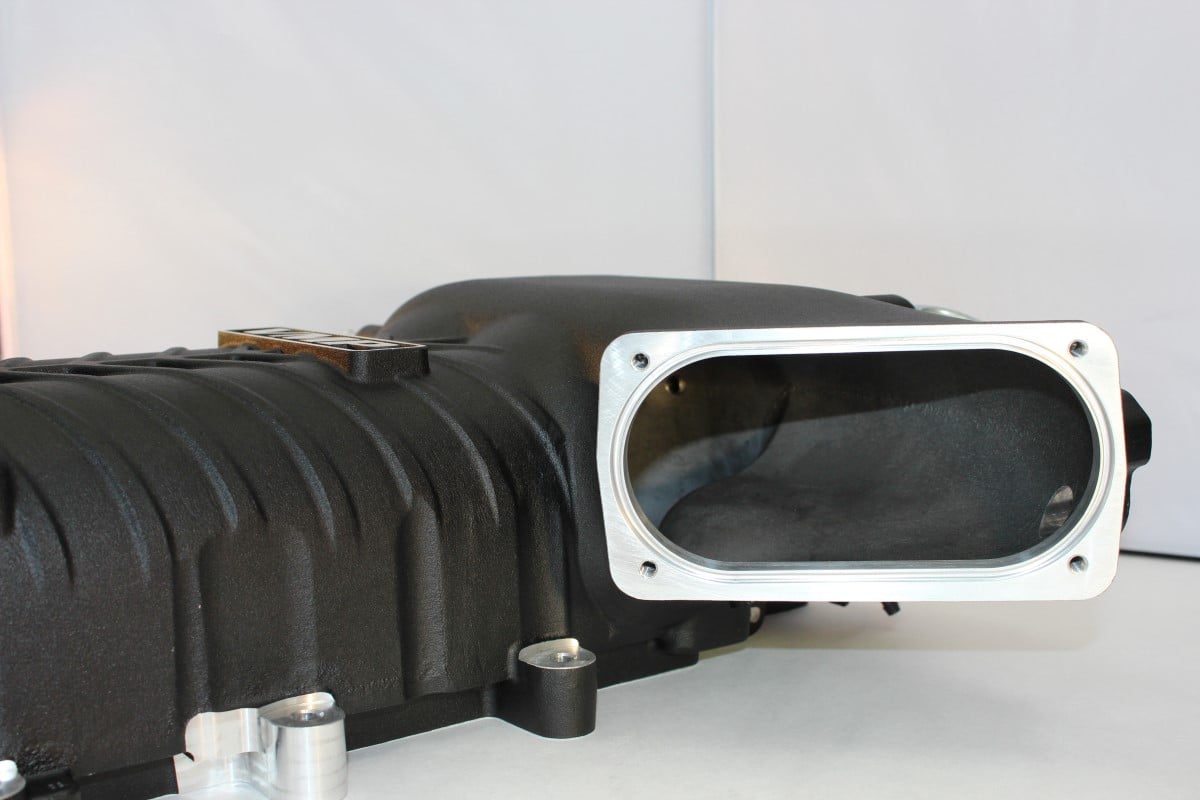

ROUSH uses a rear entry point and downward-firing supercharger on their Mustang supercharger system.

Magnuson HeartBeat

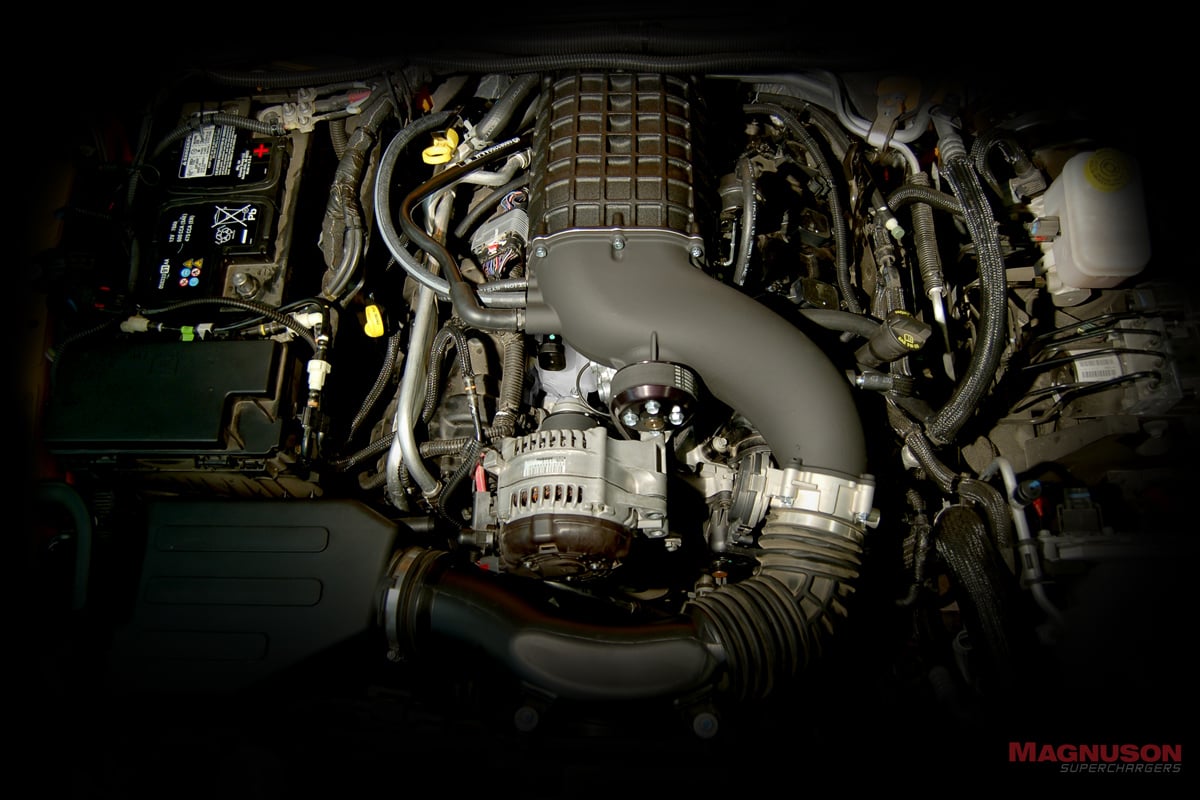

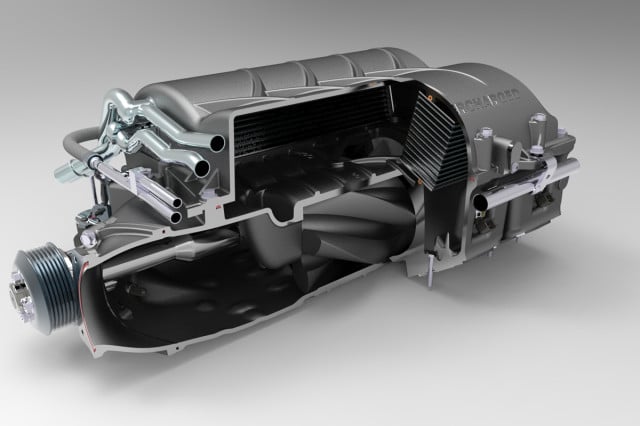

Here’s the complete HeartBeat system for the Corvette – its super-low-profile allows it to fit under the hood – a major achievement given the tight bodylines of the’Vette.

Magnuson builds supercharger systems for a variety of vehicles – perhaps the most visible is their HeartBeat system that’s designed to fit under the hood on the Chevrolet C6 LS3 Corvette. The HeartBeat is capable of over 1,000 horsepower at 15 pounds of boost, as tested by ADM Performance in Texas.

“We pride ourselves on being able to provide horsepower without compromise. We offer a kit that’s bolt-on, includes absolutely everything you’ll need, is tuned for a relatively stock engine, is emissions-legal, so that the customer who is looking for another 100-125 horsepower but isn’t willing to compromise drivability can bolt it on and go. It’s likely their daily-driver or could be a car that’s part of a collection. The HeartBeat was a big gamble for us, with an 18-month R&D project, and it was a complete departure from anything we were doing before,” explains Magnuson’s Matt Hately.

The Magnuson HeartBeat TVS system that they’ve designed for the Corvette offers Formula 1 and NASCAR heat exchanger technology in the intercooling department. A pair of dual-pass charge air coolers reside in the inlet manifold, above the upward-firing supercharger but prior to the cylinder head ports.

“Our distributors are fully trained to build superchargers to Eaton’s production specification.” – Grant Terry, Eaton Corporation

The intercooler design is built to handle the repeated, hard use the customers will put it through. The supercharger in the C6 HeartBeat kit discharges upwards into the plenum, which splits the air into the two banks. There is an intercooler brick on each side that sits in the curved section of the plenum and runs its length just prior to the port opening for maximum efficiency. It also assists in improving air distribution – as air backs up in the plenum it finds its way to every port equally through the intercooler bricks.

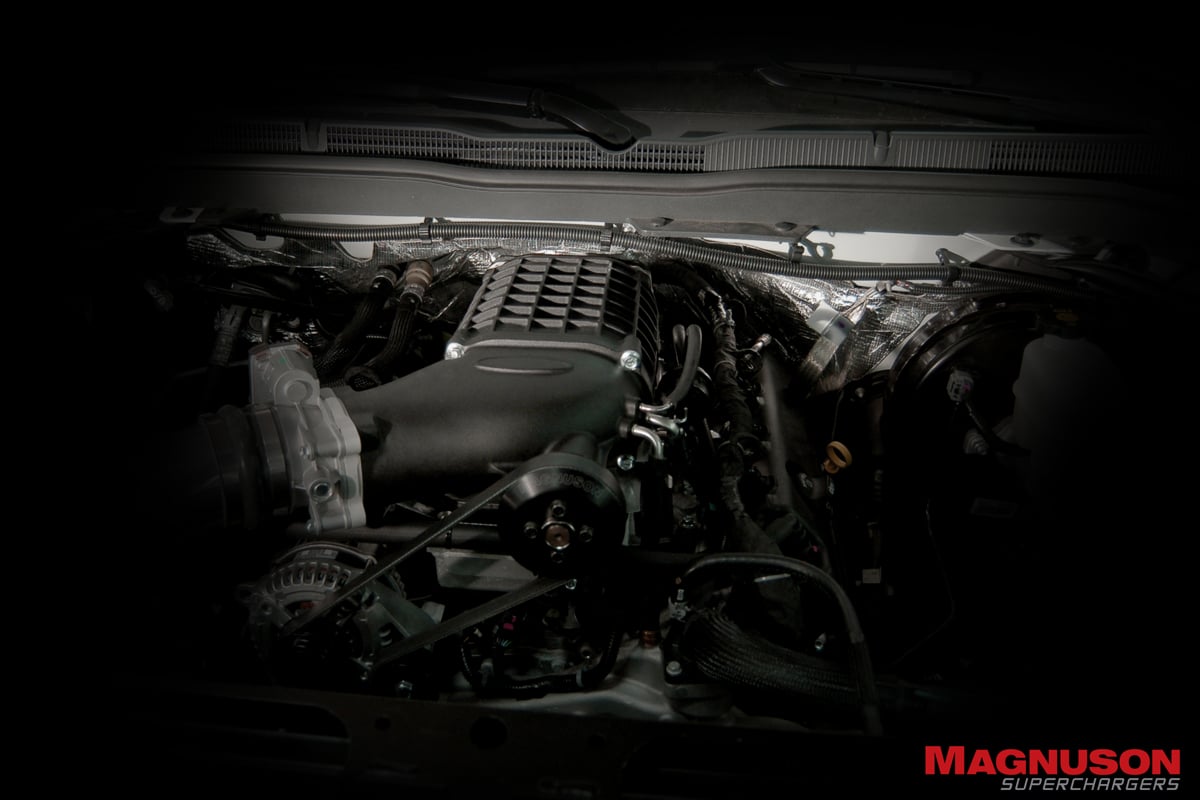

Left - Magnuson's 3.6L Jeep fitment uses the TVS1320. Right - The Magnuson system for the GM truck platform uses the TVS1900. The company prides itself on developing complete solutions for each platform - the goal is to build supercharger kits you forget are installed, until you step hard on the throttle.

They have a supercharger system for the C7 Corvette currently in development that will build on the success of the C6 HeartBeat system’s design.

Magnuson uses the TVS design in its various forms to produce many other supercharger packages – the TVS1900 for the GM trucks, the TVS1320 for their Jeep 3.6L packages and the TVS900 for the Lotus Elise, along with TVS2300 Mustang and Challenger applications.

Each of these systems is engineered specifically for the vehicle application and Magnuson’s own internal engineering to provide substantial performance improvements across the board for vehicle owners. Depending upon application, the kit could include a single intercooler or the dual design like the HeartBeat, and an upward- or downward-firing supercharger.

Magnuson’s HeartBeat system for the Corvette uses an upward-firing supercharger that pushes the air through dual-pass charge cooler cores that run the length of the intake manifold. Air stacks up in the manifold to help push the flow through the cores and distribute it evenly to the cylinders.

Edelbrock E-Force

Our conversation with Edelbrock’s Vice President of Engineering, Rob Simons, centered around the fact that their products are designed for the street enthusiast with a high level of refinement.

“Our product would not be out of place coming off an OE production line. Our E-Force supercharger kits have excellent drivability, great fit and finish, doesn’t look out of place under the hood or scream ‘I’ve been modified’ – it should look like it belongs under the hood. Aggressive and clean, and definitely tells you that the engine is supercharged, but not necessarily in-your-face placement. It’s for the guy that doesn’t want to give up anything, but wants all of the power the supercharger can produce,” he says.

Edelbrock's systems offer superior fit and finish. They're designed to be installed easily and provide the user with a big bang-for-the-buck improvement. Oh - they look good, too.

They use pre-assembled, formed hoses with permanent shrink clamps, push fittings, and wiring harnesses that are plug-and-play so that the end consumer can just lay all of the pieces out in the engine compartment and assemble the system as if it were a factory part. The company offers engineered kits for the Camaro SS, Corvette, Chrysler HEMI, Dodge Truck, Mustang, and Ford and GM trucks and SUVs along with a GM Universal kit – and the Enforcer systems detailed below.

Simons takes great care during the development process to create kits that can typically be assembled on a Saturday and driven to the local cruise-in on Saturday night. “Everything we have is purpose-built and integrated – you minimize the gasket surfaces by using one casting, which also allows us to build a more compact, cleaner-looking unit with better reliability,” Simons explains.

One item that he’s very proud of relative to their kit design is the fact that every single one of the systems has been developed and tested on one of Edelbrock’s fleet of test cars. Their tuning calibrations are created in-house, as they have three calibrators on staff whose sole responsibility is to build tunes that will perform in any situation the customer might encounter.

Edelbrock’s Eric Blakely adds, “The internal bypass allows the TVS blower to be ‘unloaded’ during constant manifold vacuum periods thereby creating less parasitic drag on the engine. By contrast, a twin-screw blower can never truly be unloaded even with a bypass, because if it is spinning, it is compressing air whether it is needed or not. A TVS2300 supercharger consumes less than one horsepower to spin when the bypass is open under normal cruise conditions.”

Edelbrock is unique among the companies we spoke with in that they also produce their Enforcer Series of TVS supercharger systems, which combine modern efficiency and power with traditional hot rod looks. The LS Enforcer comes in both EFI and carbureted fitments and is designed for use on the LS engines using rectangular port cylinder heads. It’s a great way to transplant supercharged LS power into your older hotrod but gain the reliability, efficiency, and performance of the TVS design. They are sold in several different configurations.

Check out the Enforcer Series TVS supercharger from Edelbrock, designed for the small-block Chevrolet. It’s designed to mimic the appearance of an old-school blower while providing current-day technology. These are available with either carburetion or Edelbrock’s Pro-Flo fuel-injection as shown here.

Carbureted Enforcer systems include the supercharger, intake manifold with rectangular ports, and intermediary adapter plate, and are delivered with drive pulleys, a 10-rib serpentine belt, and all of the necessary installation hardware. With dual 4150-style flange mounts atop the supercharger, they require a pair of carburetors, which Edelbrock can also provide from their Performer series – or you can source your own.

The EFI version of the Enforcer includes all of the necessary supercharger components but adds a bar-and-plate intercooler to the kit; you’ll also need a heat exchanger, which is sold separately, along with a pair of throttle bodies and engine management software.

Street Legal Performance

The team at Street Legal Performance (SLP) is a sister company to ROUSH Performance. ROUSH purchased SLP a few years back and moved production to their Livonia, Michigan headquarters with an intent of developing the SLP product line to the same standards that ROUSH has shown on the Ford side of the equation.

To that end, many of the same engineering principles used by ROUSH are front-and-center throughout the development process of the SLP line of TVS superchargers, which to this point have been engineered for the 2010-’14 Camaro SS and 1LE models, along with the 2009-’13 5.3 and 6.2L Silverado/Sierra/SUV platforms.

Here’s an internal view of one of SLPs TVS systems. Air enters the supercharger from the front, flows through the rotors, and fires straight through the intercooler and into the cylinder heads.

The SLP system for the Camaro fits both the LS3 and L99 engines, with 575 horsepower available on the LS3 and 550 horsepower on the L99. This system was designed to be a clean-sheet exercise in supercharging the 6.2L Camaro, and as such uses a direct drive rotor pack that eliminates the need for a jackshaft, extra bearings, extra pulley and rear belt. The intake manifold ports have been designed from the outset to be matched to the port dimensions of the cylinder head for improved flow.

Like the ROUSH Mustang systems, the SLP systems come with everything you will need for installation – the fueling components, intercooler, low temperature radiator, intercooler pump, and new high-travel belt tensioner along with the belt, brackets, and all other extra hardware is in the box.

“We don’t have a vehicle program on the GM side like we do on the Ford side, but all of the same engineering principles that we put into the ROUSH product, we mirror on the SLP side. The SLP company does leverage a lot of the ROUSH resources as far as how they develop the product. The casting is different, but the system itself is developed in a similar manner. Our fuel charging assembly on this system is underneath the supercharger instead of on top. From a performance standpoint, we feel that it’s a straighter, more direct path into the engine, and you’re getting an instant cool charge into the cylinder head,” explains Velthoven.

The SLP systems are developed using the same engineering practices that are used by sister company ROUSH Performance. Kits are available for a variety of GM and MOPAR vehicles.

VMP Tuning

VMP Tuning specializes in the Ford Mustang – owner Justin Starkey worked at SCT as part of their technical support staff before heading out on his own. When Starkey purchased his first GT500 back in 2006, he immediately began looking for horsepower improvements.

Eventually he settled on the TVS, and has been building improvements into the design ever since. VMP’s newest TVS design has just hit the market and offers upwards of 50 horsepower gains at higher boost levels. The GENII system features a one-piece elbow/blower design, 18 percent more airflow than the previous-gen VMP TVS into the supercharger, and optimized inlet geometry.

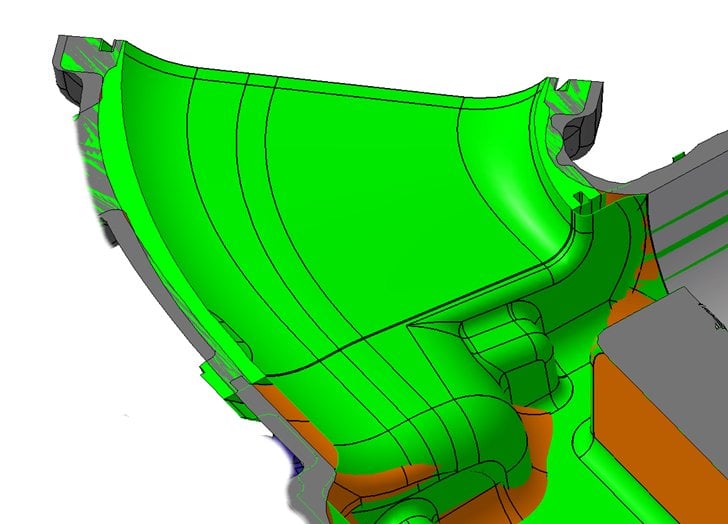

VMP Tuning has taken a bit of a different tactic with their version of the TVS. This is the second-generation product and features serious airflow enhancements. The green areas in the left photo is where they were able to open up the entry elbow form the previous version supercharger.

“We have some performance advantages and uniqueness in our design as we are using a rear-entry supercharger for our TVS kits. It allows us to get a lot of air into the supercharger. We have to turn the air, which is a challenge, but we feel that we’re able to get more air into the supercharger due to our design – there is no driveshaft in the way of the air entry, and we’re able to use an oval throttle body to supply that air,” Starkey says.

A side-by-side view of the VMP GEN II TVS and the factory 2013-’14 GT500 supercharger. The VMP GENII TVS product has outperformed the factory unit by leaps and bounds in the horsepower department.

There are some differences in the TVS package between the rear-entry TVS kits offered by VMP Tuning and the front-entry Mustang kits offered by some of the other manufacturers in our roundup, and Starkey cautions that the ultimate horsepower capability is not the same between kits and manufacturers due to the differences in design and function.

Currently they offer 2.3-liter TVS kits for a wide range of Ford vehicles like the 5.0L Mustang and F-150, the BOSS 302, Shelby GT500, and more. VMP Tuning differs from the other companies in this article in that they service a group of enthusiasts that spends plenty of time at the racetrack. Whether it’s a dragstrip or a road course, the VMP Tuning customers are flogging their vehicles often, which provides the company with a wealth of real-world data and feedback on their system performance. In fact, according to Starkey, the company has produced the highest-horsepower stock-engined 2013-’14 GT500, producing 823 RWHP and 833 foot-pounds of torque on E85 fuel with the new GEN II.

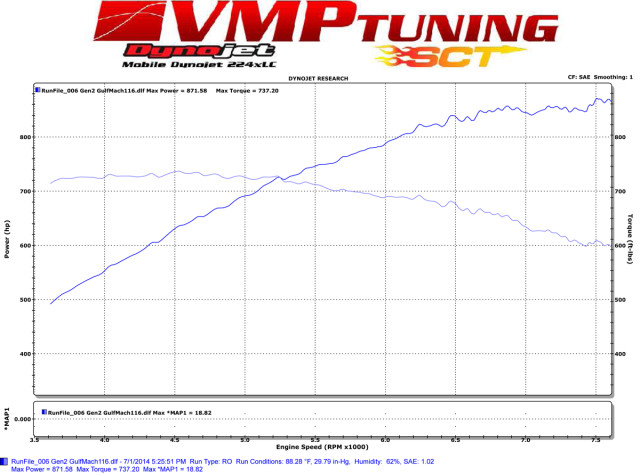

In a recent dyno session with the brand-new Gen II TVS on his own personal BOSS 302 Mustang, Starkey coaxed 871.5 horsepower and 737.2 horsepower on Gulf Mach116 fuel.

VMPs kits are downward-firing, which places a high-efficiency intercooler in the valley between the cylinder heads, with the supercharger exhausting directly into the cooler. The difference with this design as compared to some of the others profiled up above is that it requires an intake manifold with much shorter runners and a larger intercooler.

All of the company’s GT500 and 5.0L Coyote kits are transitioning to the new GEN II design, which is totally unique to VMP. The company is the first to tool up an OEM-style one-piece housing high efficiency TVS replacement supercharger for the 2003-’04 Cobra, nearly 10 years after the cars debuted.

“In the GT500 market, everyone looks at porting the superchargers and making them bigger to make more horsepower, so we decided to just go ahead and design the supercharger to have the huge inlet to begin with. When we designed our newest supercharger, we really started to think outside the box to figure out how we could get the most air into the supercharger. By casting the housing and inlet as one piece with no bolt-on elbow, we’re able to lower the inlet floor, get the air in and turn it more efficiently and thus make substantially more power over our older design,” says Starkey.

VMPs Justin Starkey has a large contingent of customers in the Shelby GT500 crowd and tailors the GEN II towards the higher-boost applications to make those cars really shine.

Starkey has found that the more air the supercharger is able to ingest, the more power the supercharger is able to make. VMP Tuning offers all of the supporting gear to go along with their kits that you might expect, like a larger dual-fan triple-pass heat exchanger, custom tuning, bigger throttle bodies, and more.

Wrapping Up

A wide range of options exists here for enthusiasts of all types to take advantage of for each particular application. Whether you’re rolling around in a C6 Corvette, 2014 Mustang GT, or LS-swapped ’69 Camaro, the ability exists to fit a TVS-based supercharger on your ride. With the immense availability of kits for such a diverse collection of vehicles from a wide range of manufacturers, we couldn’t possibly profile them all here.

Regardless of whether you’re seeking a kit that appears and performs as if it were installed at the factory or one that will propel your ride into the stratosphere at the dragstrip, turning your mild-mannered machine into a fire-breathing supercharged monster is only a phone call away.