In this day and age, we take fuel injection for granted. It’s sad, but true. Throughout the mid-80s and the early 90s, fuel injection became the primary system used in feeding fuel to new automotive engines, replacing the carburetor.

In this day and age, we take fuel injection for granted. It’s sad, but true. Throughout the mid-80s and the early 90s, fuel injection became the primary system used in feeding fuel to new automotive engines, replacing the carburetor.

Have you ever taken a step back while working on your vehicle and thought about how far fuel injection has come? We recently did, and it was a great realization. Thinking about fuel injection in racing got our minds… well, racing. Linking back to the first fuel injection systems used in racing applications brought up the legendary Russ Collins. Collins began drag racing motorcycles in the late 1950s, and by the mid-’60s he was a top authority on high-performance motorcycle engines. He even built a few crazy creations himself in the ’70s. The bikes he built really flipped the script on the competition and left them no choice but to up the ante.

Have you ever taken a step back while working on your vehicle and thought about how far fuel injection has come? We recently did, and it was a great realization. Thinking about fuel injection in racing got our minds… well, racing. Linking back to the first fuel injection systems used in racing applications brought up the legendary Russ Collins. Collins began drag racing motorcycles in the late 1950s, and by the mid-’60s he was a top authority on high-performance motorcycle engines. He even built a few crazy creations himself in the ’70s. The bikes he built really flipped the script on the competition and left them no choice but to up the ante.

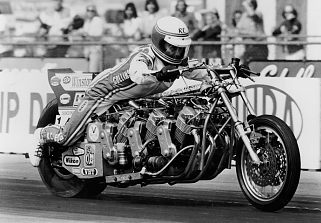

Collins’ bike, “The Assassin” was the first motorcycle to run a dual Weber carburetor setup, and later on, it was the first motorcycle engine to run fuel injection and have a supercharger. The 400 hp Honda-engined drag bike was so fast, it forced competitors to run dual Norton engine setups. In 1986, RC Engineering struck a deal with Honda to supply engines to factory-supported teams in the popular SCCA/ESCORT endurance series, IMSA Firehawk series, and the SCCA World Challenge.

This is Collins’ triple-engined Honda drag bike he built and named the “Atchison, Topeka, and Santa Fe.”

The problem Collins had with the modern four-cylinder Honda engines was the fact that modifying the fuel injection systems was no easy task. Getting fuel to the rail and injectors wasn’t a problem; it was the injectors that were holding him back. Collins started playing with different injector sizes, as well as taking injectors from other manufacturers and modifying them to fit his Honda engines.

“At that point, I built my first injector flow bench, which we still use every day, here at RC Engineering.” said Collins in an interview from 1998. “Once we understood how injectors worked and how much they could flow, I realized we could adapt ‘larger’ ones from other sources to engines that needed more fuel flow.”

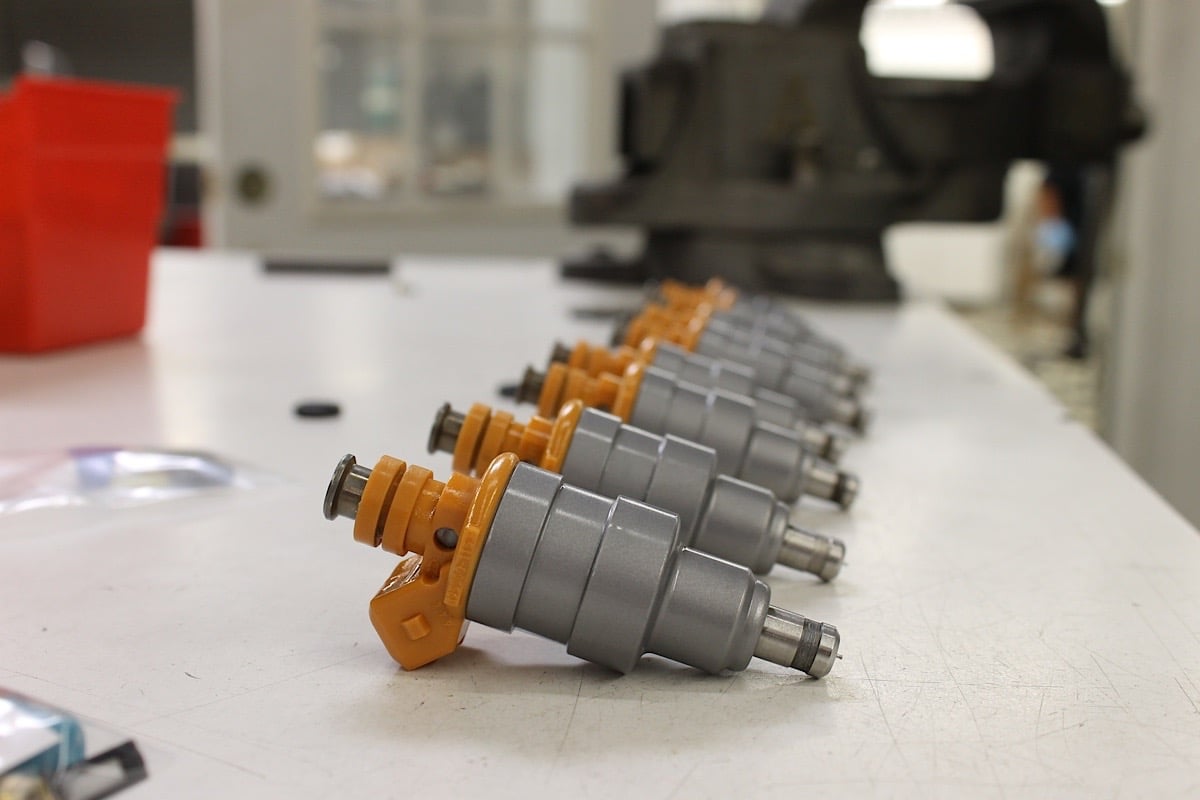

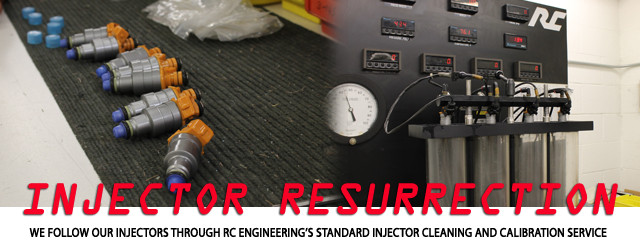

Collins built another two flow benches, in addition to his first one, and they’re still used at RC Engineering to this day. We had a set of Bosch injectors lying around that needed cleaning and calibration, so we set out to RC Engineering in Torrance, California to follow the injectors through the process.

Why would you need to clean your fuel injectors? It’s simple: the injector’s life is prolonged, and the engine will run more efficiently. Services like RC’s don’t only clean out the injectors, they make sure that the injector as a whole is functioning correctly. If there is a bad injector, they will definitely let you know.

With automotive manufacturers designing fuel systems that don’t require maintenance until the 100,000-mile mark is reached, there’s really no reason to have the injectors cleaned within the first two to three years of ownership. As far as racing goes, you want to make sure your injectors are running in tip-top shape, otherwise performance will start to suffer. Some race teams clean injectors before every race, and some clean them before and after every season. It really depends on how hard the injector is working and in what amount of time. Nowadays, with road-going vehicles, the general rule of thumb is to have the injectors cleaned anywhere from 80,000 to 100,000 miles.

Testing, Cleaning, Calibrating, And Rebuilding The Injectors

Wayne Sanmiguel, a loyal and humble RC Engineering technician, was more than happy to show us the ins and outs of the whole standard injector cleaning service they provide, and we were excited to be along for the ride. RC Engineering does offer a ProCal service for cleaning injectors, and the difference between that and the standard service is a more complex calibration procedure and a more comprehensive test report.

Wayne Sanmiguel, a loyal and humble RC Engineering technician, was more than happy to show us the ins and outs of the whole standard injector cleaning service they provide, and we were excited to be along for the ride. RC Engineering does offer a ProCal service for cleaning injectors, and the difference between that and the standard service is a more complex calibration procedure and a more comprehensive test report.

“The ProCal test is more defined by the person bringing them in. We can test a fuel injector in nearly any variable, like RPM, pulse width, pressure, etc. I can test the minimum opening time of the injector or a specific volume at a specific duty cycle,” Sanmiguel explained. “With the ProCal service, we could test anywhere where the fuel injector will work, from where it first opens, to any pressure its actually operating in.”

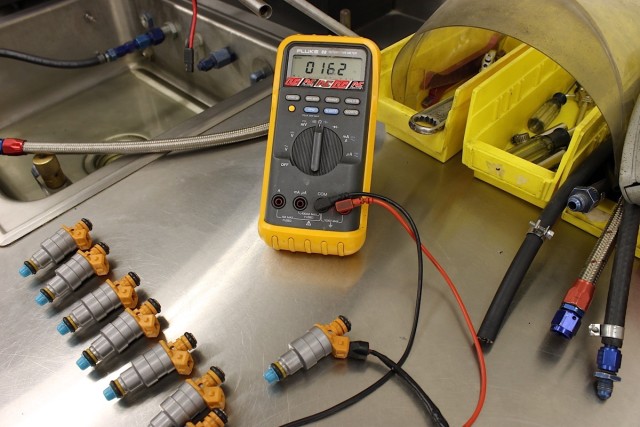

Before Sanmiguel put the injectors on Russ Collins’ home-built injector flow bench, he tested each injector with a digital multimeter to check that the impedance is consistent in all eight injectors. This test is done to ensure the fuel injector is working properly and not burned out. There are two kinds of electrical charge for fuel injectors; high impedance and low impedance. High impedance injectors like ours will show anywhere from 12 to 17 ohms, and low impedance injectors will range anywhere from 2 to 5 ohms. Our Bosch injectors all showed 16 to 16.3 ohms of resistance, which means they’re in good working order.

Before Sanmiguel put the injectors on Russ Collins’ home-built injector flow bench, he tested each injector with a digital multimeter to check that the impedance is consistent in all eight injectors. This test is done to ensure the fuel injector is working properly and not burned out. There are two kinds of electrical charge for fuel injectors; high impedance and low impedance. High impedance injectors like ours will show anywhere from 12 to 17 ohms, and low impedance injectors will range anywhere from 2 to 5 ohms. Our Bosch injectors all showed 16 to 16.3 ohms of resistance, which means they’re in good working order.

Left to right: Collins' hand-built injector flow bench, the injector set in place on the bench, and, if you look closely, you can see the injector's spray pattern.

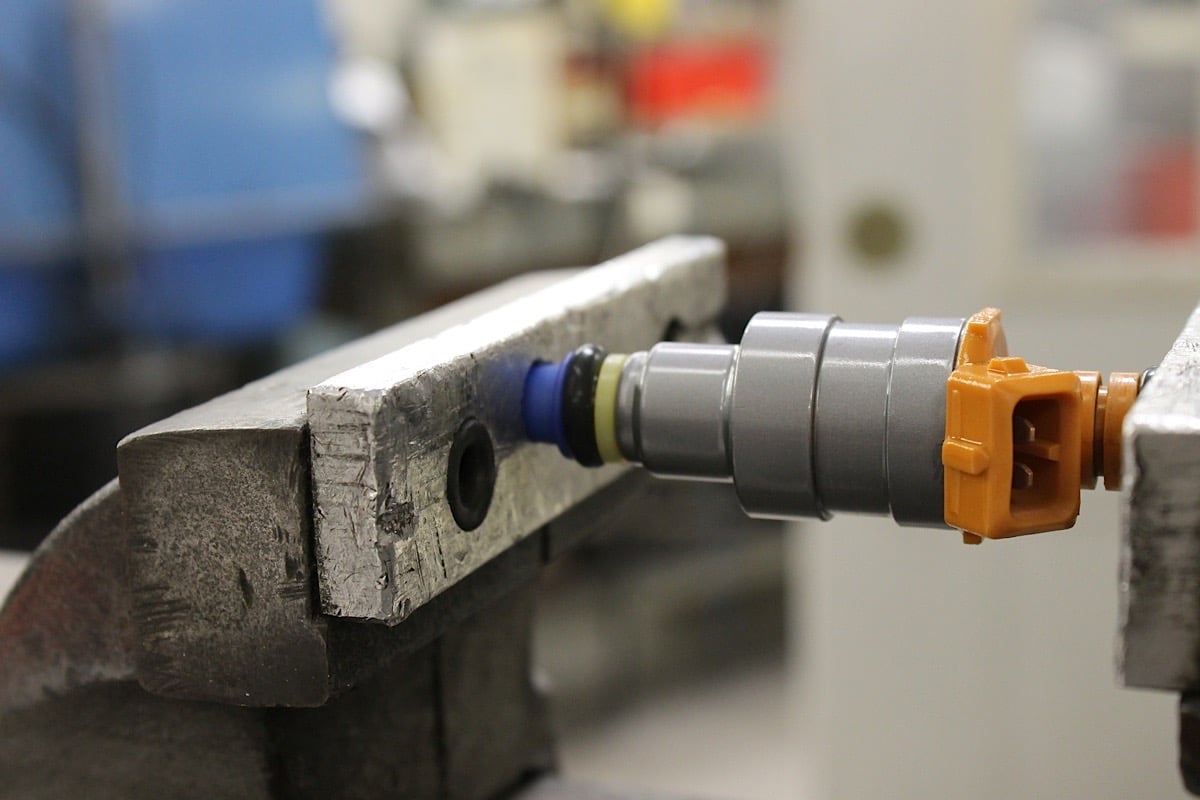

Sanmiguel tested the injectors for one minute at 43.5 psi, or 3 bar, to measure how many cubic centimeters or milliliters come out of the injectors. The flow test is done to rate how many ccs the injector flows per minute, and also to record the condition of the spray pattern before the initial cleaning process.

Sanmiguel tested the injectors for one minute at 43.5 psi, or 3 bar, to measure how many cubic centimeters or milliliters come out of the injectors. The flow test is done to rate how many ccs the injector flows per minute, and also to record the condition of the spray pattern before the initial cleaning process.

After all of the before flow testing numbers were recorded, Sanmiguel popped the injectors out of the machine and began disassembling them to get them ready for the initial cleaning process. The bottom injector cap, bottom O-ring, insulator, and filter are removed before the injectors go into the ultrasonic cleaning bath.

A look at the injector with all of the replaceable parts removed before the ultrasonic cleaning bath.

Before submerging the injectors in the ultrasonic cleaning bath, they are connected to box that powers them as if they were running on a car. The injector driver box pulses the injectors to get the fluid through all of the little nooks and crannies within the injector body while the ultrasonic bath uses cavitation bubbles induced by high-frequency pressure (sound) waves to agitate the liquid within the tank to clean the outermost parts of the injector. Our injectors were relatively clean, so they only spent about 10-15 minutes in the bath, but if RC receives a set of injectors that are ridiculously dirty, they can sit in the ultrasonic cleaning bath for up to 6 hours.

On the left is the injector being back-flushed, and on the right is Sanmiguel hitting it with compressed air.

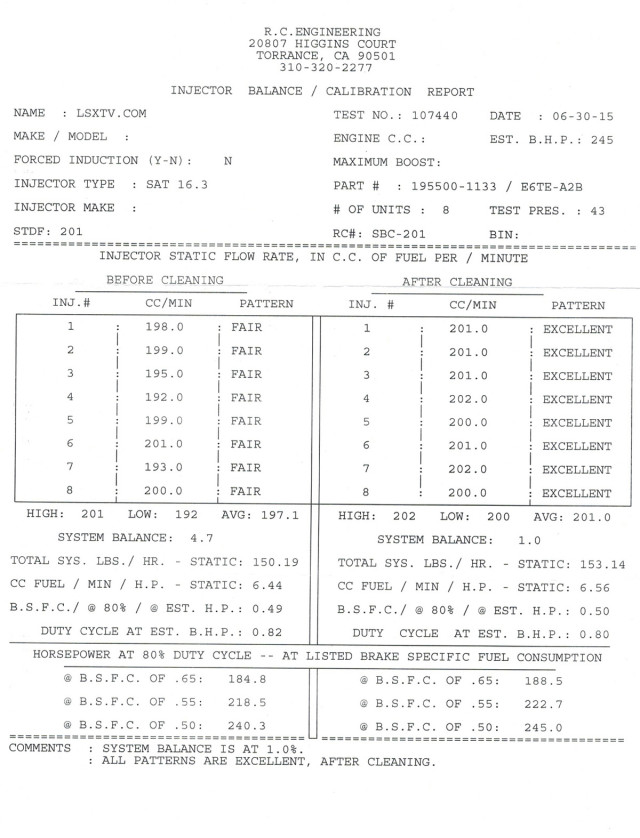

With all of the injectors back-flushed, Sanmiguel took all of them back over to the flow bench to get numbers after they’ve been cleaned. The first test showed that our injectors were flowing anywhere from 192 cc/min to 200 cc/min, which is fair; not bad, but not the best. The flow numbers that our injectors produced after the cleanse was where they really shined. With an excellent flow pattern, our injectors flowed 200 cc/min to 200 cc/min, which is exactly how they should be flowing.

With all of the injectors back-flushed, Sanmiguel took all of them back over to the flow bench to get numbers after they’ve been cleaned. The first test showed that our injectors were flowing anywhere from 192 cc/min to 200 cc/min, which is fair; not bad, but not the best. The flow numbers that our injectors produced after the cleanse was where they really shined. With an excellent flow pattern, our injectors flowed 200 cc/min to 200 cc/min, which is exactly how they should be flowing.

“The re-test is to see if the injectors are flowing even to each other, and if they need additional cleaning, they will go back in the ultrasonic bath, get another back-flush, and be re-tested until they flow within two percent of each other,” said Sanmiguel.

From left to right: Masking off the ends of the injector, the injector in the media blaster, the media-blasted injector, and the injector finished up with clear coat.

“If the injectors have never been looked at, you might want to have them checked around 100,000 miles” – Wayne Sanmiguel, RC Engineering

Once the injectors had all of the new hardware installed, they were then individually wrapped in bubble wrap and set in a box, ready for us to take them home. The last thing that goes into the box before its packaged up are printed results of the initial test and results from after they were cleaned and calibrated, along with a bunch of other useful information about the injectors that you might not have known before.

From left to right: the new injector components, the injectors being reassembled, and finally, the injectors all packaged up with the test results. Thanks, RC Engineering!