When it comes to the oiling system of your engine, some people don’t realize what a large role the oil pan plays in the overall performance equation. Choosing the right pan for your specific application is a lot more important than just asking the question “What will fit my engine and chassis?” – it is such a critical component that can alter the performance of your engine.

In collaboration with two of the largest names in the oil pan business – Moroso Performance Products and Canton Racing Products – we’re here to give you the lowdown on all the different options available regardless of engine platform. Even though an oil pan is at the bottom of your engine, it shouldn’t be at the bottom of your list when it comes to putting in the time and effort to get the proper pan.

“Anybody who is spending the time, money and thought process on a built engine should make their oiling system a high priority. Why risk the investment or cut down on the potential of a built engine by not using the proper oiling system?” says Thor Schroeder, Marketing Manager for Moroso.

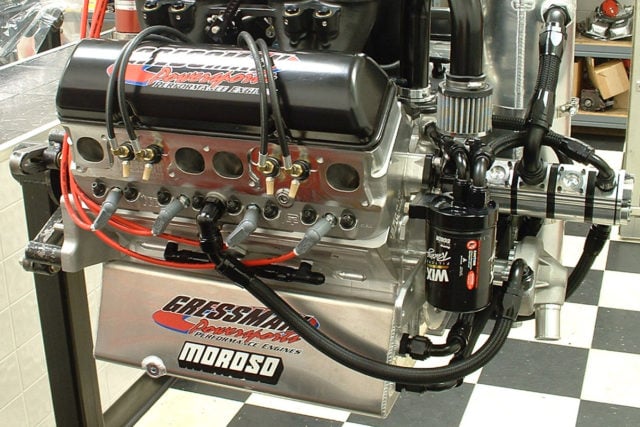

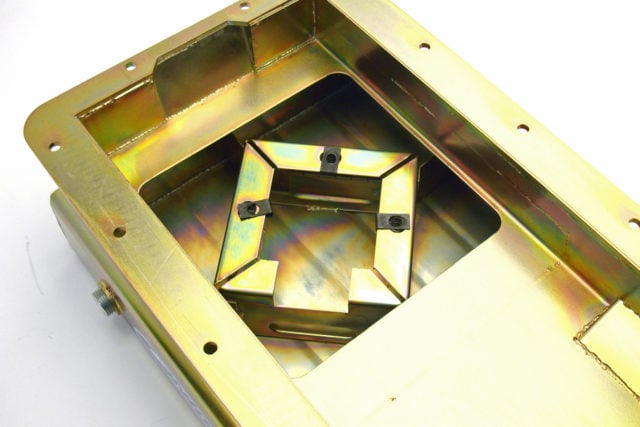

This dry sump pan has been custom-built for this specific application. For most applications, a suitable off-the-shelf option exists, but for more exotic combinations a custom pan may be most beneficial.

Step One – Planning the Right Pan

As the old adage goes, “Prior Planning Prevents Poor Performance,” and choosing an oil pan is no different.

“A person should not just look at an oiling option that takes care of the situation at hand but the person should think long-term about what they are going to do with the car and expect out of it,” says Schroeder. Canton Racing Products’ Marketing Coordinator Jeff Behuniak elaborates: “First, we need to establish the type of engine and the features of the engine such as stroke and oil pump. Then we need to know the chassis that the engine will be in and what the car will be used for. This is important to first make sure that the engine will fit and secondly that the oil pan will perform in the desired arena.”

Anybody who is spending the time, money and thought process on a built engine should make their oiling system a high priority. – Thor Schroeder, Moroso Performance Products

“A stamped pan is limited in what features it can utilize, while a fabricated oil pan can include just about any feature that can fit,” explained Behuniak. To that end, Schroeder explained why there are some applications in their catalog which are low-feature, but fully-fabricated designs. “Some aftermarket racing engine blocks have never had a stamped oil pan created for them due to the low production numbers of these engine blocks.”

While a stamped pan like this one from Moroso is an economical option, they generally don’t have much in the way of high performance features.

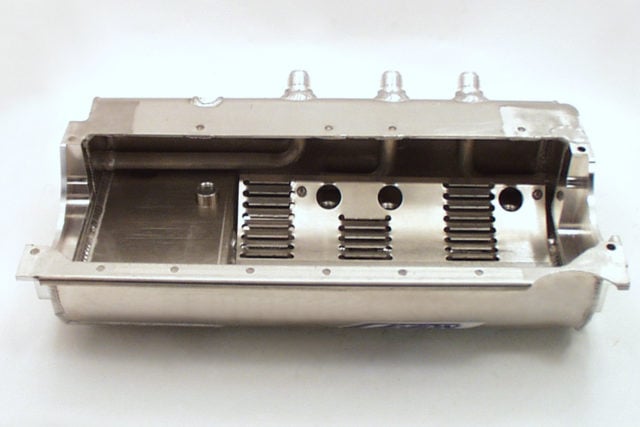

The next initial determination, which isn’t really on the forefront of a lot of people’s minds when they select an oil pan, is pan material. The two options are the age-old automotive either-or: steel or aluminum. Both have their advantages and drawbacks.

“Steel is heavier than aluminum, obviously but it’s also stronger, and holds up to impact better. It’s also easier to fix in the field. Aluminum, however, is lighter, offers far better heat dissipation, and doesn’t need to be painted or coated to prevent corrosion,” says Schroeder.

In an application where oil temperature control is a significant factor and the chances of damaging your pan are minimal, like road racing, aluminum seems like a shoe-in. In a non-wheelie-bar drag race application, where the potential for smacking the pan on the return to terra firma is a likelihood, the ease of repair of a steel pan might be a factor to consider. So we already have a number of factors to consider, and we haven’t even gotten inside the pan yet.

Aluminum vs. Steel: It’s not just about the weight. An aluminum oil pan is lighter, and will help dissipate heat from the oil better, whereas steel pans are stronger, more robust, and more easily repaired in the field.

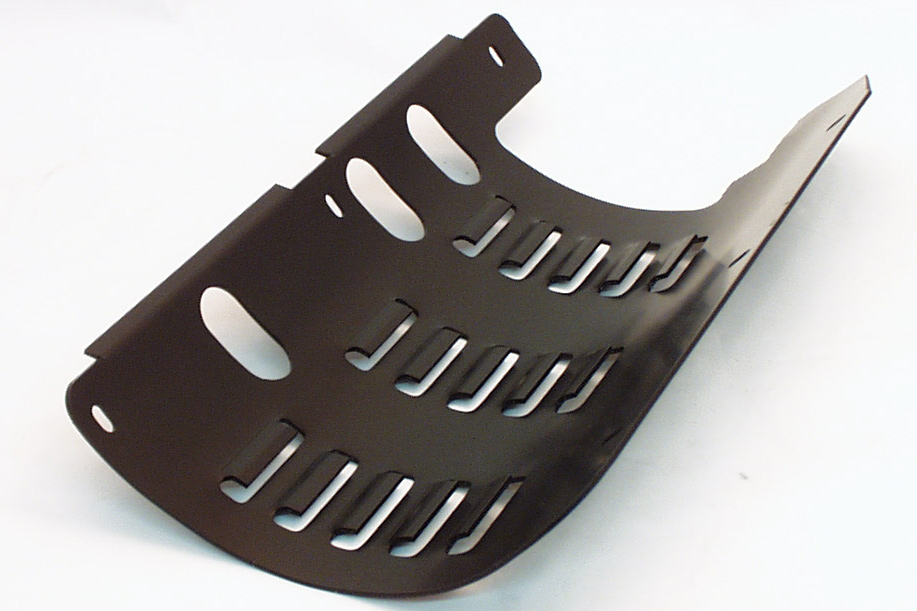

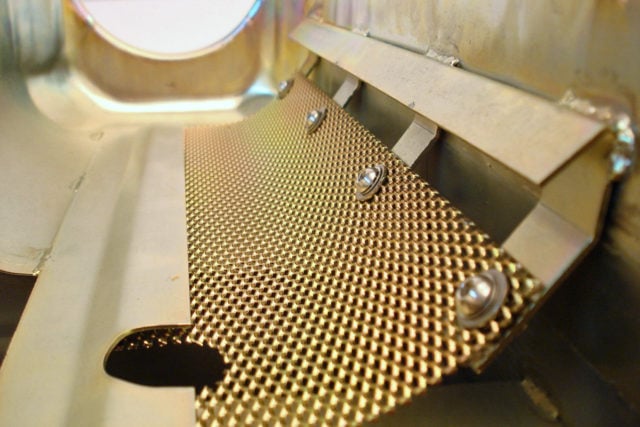

Windage Trays and Crank Scrapers

Every internal feature of an oil pan is aimed at one thing: oil control. The first important feature for an oil pan to have is a crank scraper. As the name implies, the crank scraper controls the oil that comes off of the rotating crankshaft. However, “scraper” is a bit of a misnomer, as the scraper and the crankshaft don’t actually contact one another. “To get a crank scraper to perform optimally it should be trimmed to be as close to the rotating assembly as possible,” Behuniak explained. Schroeder continued, “The crank scraper is designed to direct the oil that is flinging off the crankshaft back into the pan efficiently and with a minimum of turbulence.” Per Behuniak, the only time a crank scraper is omitted from a pan’s design is if the engine’s stroke is so large that there is no way to physically fit a scraper in the pan.

Crank scrapers are designed to catch and collect oil being slung off of the rotating crankshaft. Ideally, the scraper is positioned with the least amount of clearance possible between the blade and the crankshaft.

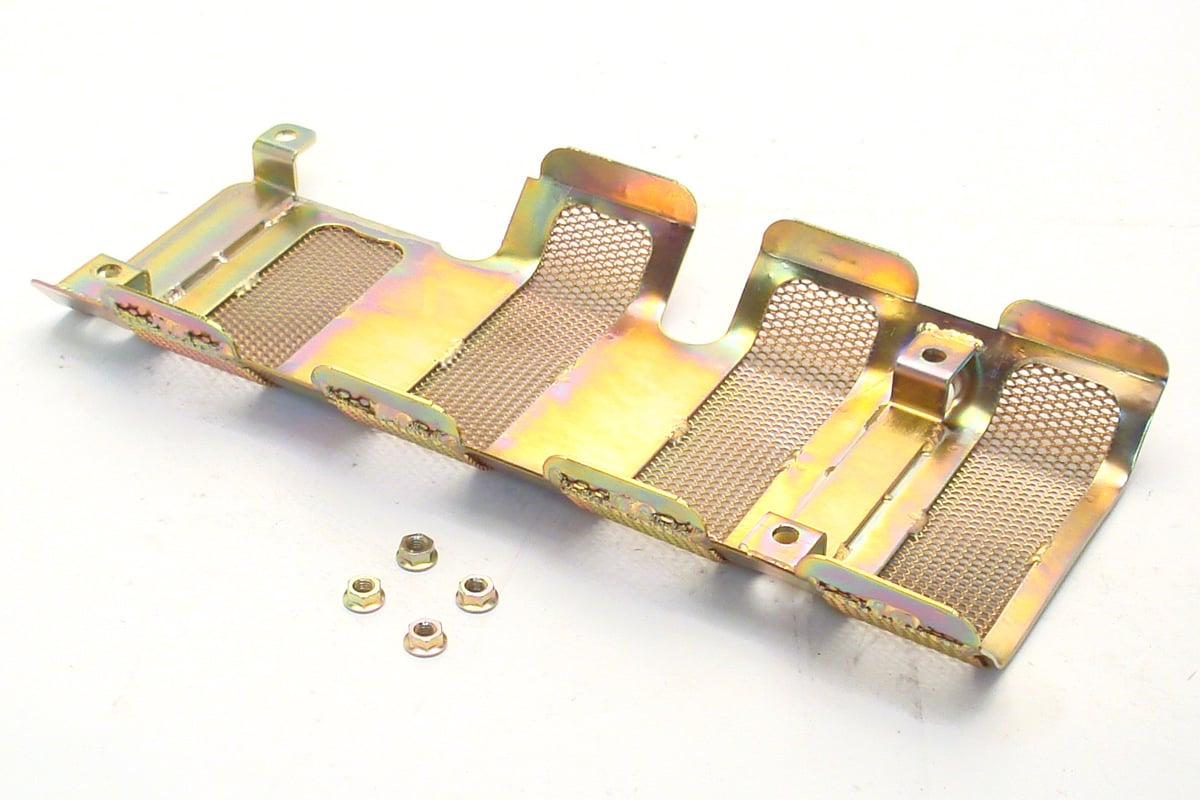

The next oil control item is a windage tray. Schroeder was quick to point out that the term “windage tray” has come to mean different things to different people.

“The term windage tray has been broadened to represent a couple different features in recent years. Often the sheet metal plate that goes over the opening of the sump where it meets the body of the oil pan has been called a windage tray. This is actually the anti-slosh baffle, which is important in keeping the oil contained in the sump so that it does not get back into the rotating assembly. The windage tray itself is the screen or louvered piece that is either mounted directly to the main caps of the engine or in the oil pan itself and usually has a crank scraper as a component of it,” he says.

To get a crank scraper to perform optimally it should be trimmed to be as close to the rotating assembly as possible. – Jeff Behuniak, Canton Racing Products

“At Moroso our windage tray designs live and die by our in house dyno, outside testing, and our group of top engine builders and racers that we use to test our products,” says Schroeder.

“Some engines, oil pans, and uses of the engine are affected more than others with running or not running a windage tray.”

He elaborated upon the factors which affect how effective a windage tray might be, saying, “Engines that are static, have a big box oil pan that keeps the oil away from the crank, have a conservative rod and stroke combination, and are operated in a RPM range that is less than 5,500 are going to be affected less by not using a windage tray.”

So now you’re wondering how much power a windage tray is worth, right? Well, Schroeder says they have seen up to a five percent horsepower difference, along with lower average oil temperatures and more consistent pressure.

Windage trays come in several varieties - with a mesh and louvered design pictured here. Their function is to isolate the oil in the pan from the turbulence of the rotating crankshaft. The turbulence created by a rapidly spinning crank can raise the oil temperature and lead to frothing.

Pan Depth and Shape – What Difference Does that Make?

The Power Pouch

There is another type of kickout in the oil pan world.

“A power kick out (or the other term is “power pouch”) is an area on the side of a non-skirted engine oil pan that lets the oil vapors from the crank escape to, which will free up horsepower and help with oil temps,” says Schroeder.

“The struggle essentially comes down to capacity versus ground clearance. In an application that needs a shallow pan, you can kick the pan out to the sides to maintain or increase capacity. Kick-outs are desirable feature if your header and chassis clearances allow it and you are looking for a capacity increase,” says Behuniak.

However, kickouts aren’t a magical band-aid, as their use brings about another challenge – keeping the oil at the pickup. Imagine you have a cup of soda with a straw in it. No matter how you jostle the cup around, the straw has an ample supply of soda to draw from. Now take that same soda, and pour it into a shallow, wide Tupperware container. If you slosh the soda around in that vessel, while the straw stays in a constant position you’re going to end up sucking down a lot of air and getting the hiccups. Unfortunately, if we run that analogy to an engine and its oil, sucking air does a whole lot worse than the hiccups.

When ground clearance issues necessitate a shallower pan, kickouts are the answer to increasing oil pan capacity.

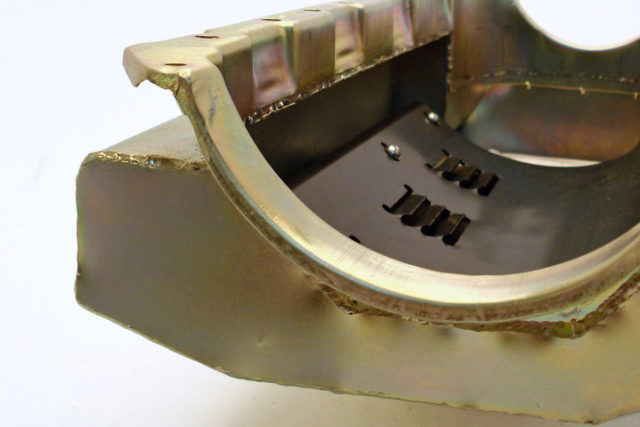

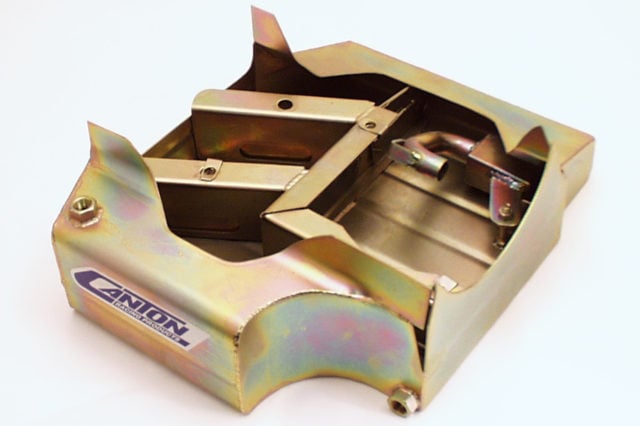

The solution is baffling. To control the motion and location of the oil in a shallow pan with kickouts, a combination of fixed and trap-door baffles can be employed.

Behuniak elaborates: “Typically when kick-outs are used, trap doors are also used in order to prevent the oil from having too much space to escape.”

To clarify, a trap-door is a one-way hinged baffle, which will allow oil to flow freely in one direction, but if the oil tries to reverse direction, its pressure closes the flap, restricting the flow of oil and preventing stavation.

“It’s critical to have the right kind of baffling and trap doors to keep as much oil as possible around the oil pump pickup inlet,” said Schroeder. The ideal location, design, and directionality of the baffling inside of an oil pan are very dependent on the type of intended use, as there is no real “do-all” design.

When kickouts are part of the design, keeping oil contained around the pickup is accomplished through the use of both fixed and trap-door baffles inside of the pan.

Pan Applications

Now that we’ve talked about what the basic features of an aftermarket oil pan are, let’s get down to brass tacks – which features are right for you. You’ll notice in most catalogs the manufacturers have categorized the pans for you, with terms like “Street/Strip,” “Road Race,” “Drag Race,” and “Circle Track”.

Behuniak broke down the naming conventions Barney-style for us.

“Each pan is built with its purpose in mind. A street/strip pan will be a bit more basic as it doesn’t need a lot of extras to maintain a street car performance level. A drag racing pan will feature everything possible to free up horsepower and shave off ET. A road race pan needs to be able to cover all the different G-forces and engine strain that a road race car experiences. A circle track pan needs to handle hard left turns and sustained RPM,” he says.

Trap door baffles are, as the name suggests, one-way flapper gates that promote oil movement in one direction and impede its flow in the other.

Schroeder dug into the technical aspects of what happens in the different types of pan designs.

“The drag race pan might have a trap door baffle in it to capture oil at the back of the oil pan and release this oil when the trap door opens up during de-acceleration. It might also be designed to work with a big stroke, and have power pouches/kick outs to free up horsepower. In road racing, the car has to accelerate hard, brake hard, and turn right and left hard. The baffling has to be able to deal with all of that and keep the pickup fed. Circle track racing requires that the oil pan be baffled in such a way the oil is directed to and contained in the right rear corner to get collected,” he says.

All-Around Performer

One last thing that we asked our experts was for a recommendation for an all-around performer. Both Behuniak and Schroeder recommended that you will get more performance gains by tailoring your oil pan to your desired motorsport. However they both agreed on what type of pan is the best compromise.

“In an unsure application, we typically recommend using a road race pan. You will sacrifice some horsepower maximization features but you will maintain more consistent oil pressure,” says Behuniak.

Schroeder concurred. “Road race oil pans are the oil pans that I like to see more people use. They cover the widest range of oil control under turning both directions, under acceleration and deceleration.”

Between the Moroso and Canton catalogs, most common applications are covered. However, should you find yourself in a position where a part number for the ideal oil pan for you application doesn’t exist, each company offers custom oil pan building services. Whether you are using an obscure engine or engine/chassis combination, or you just have odd chassis constraints, you can easily design a pan that will fit, with all the features you want (or don’t want) in it.

The most universal design, as agreed upon by both experts, is a road race-style pan. It provides effective baffling for acceleration, deceleration, and both left and right turns.