There’s an old adage that nothing new pertaining to the internal combustion engine has been invented since 1948. Superchargers, turbochargers, alternate fuel, electric-assisted engines, and even fuel injection all has its roots either before or during World War II. Believe it or not, the wheels got moving on the development of functioning fuel injection as far back as 1883 with Edward Butler, as well as E. J. Pennington, who held a patent for a motorcycle system in 1896. Not long after, Herbert Akroyd Stuart developed a crude ancestor of modern fuel injection, which was later adapted by Robert Bosch to replace Rudolf Diesel’s original system.

Yet, it wasn’t until World War II, when the Robert Bosch company was hired by Germany to develop fuel injection for its rapidly evolving aviation development. Simultaneously, both Great Britain and the United States combined their efforts to master fuel injection for the Patton tank, the Wright R-3350, and the B-29 Superfortress. After the war, most aircraft industries abandoned fuel injection and turned towards jet engines, while auto manufacturers retooled from making tanks, planes, and weaponry, back to automobiles.

Yet, it wasn’t until World War II, when the Robert Bosch company was hired by Germany to develop fuel injection for its rapidly evolving aviation development. Simultaneously, both Great Britain and the United States combined their efforts to master fuel injection for the Patton tank, the Wright R-3350, and the B-29 Superfortress. After the war, most aircraft industries abandoned fuel injection and turned towards jet engines, while auto manufacturers retooled from making tanks, planes, and weaponry, back to automobiles.

Fuel injection seemed to be a distant thought until 1949, when an Offenhauser-equipped race car entered Indy. Developed by Stuart Hillborn, the indirect-injection system wowed crowds, although the car in question didn’t win. Fuel injection didn’t enter into the commercial gasoline engine fray until the mid-1950s, most notably, on a Bosch-developed design introduced on a ’55 Mercedes-Benz 300SL. Using a standard fuel pump that supplied fuel to a mechanical injection pump with individual plungers for each injector, the system pumped high-pressured fuel directly into the engine’s combustion chamber.

While Bosch was working with Mercedes, Chevrolet was hard at work on a fuel injection system of their own. Developed and engineered through GM’s Rochester Products division, the Rochester Ramjet mechanical fuel injection system for Chevrolet’s 283 V8 engine in 1956, marketed for the 1957 model year. Of course, the development of the Ramjet – spearheaded by legendary Chevrolet Motor Division pioneers Harlow H. Curtice, Harley J. Earl, Edward N. Cole, Harry Barr, Zora Arkus-Duntov and John Dolza – coincided with Chevrolet’s Corvette effort.

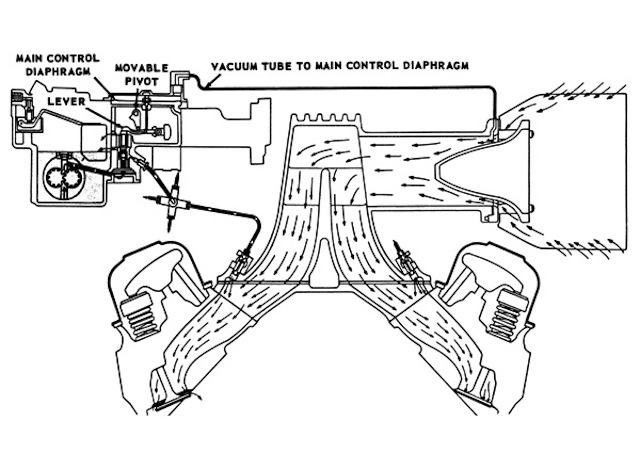

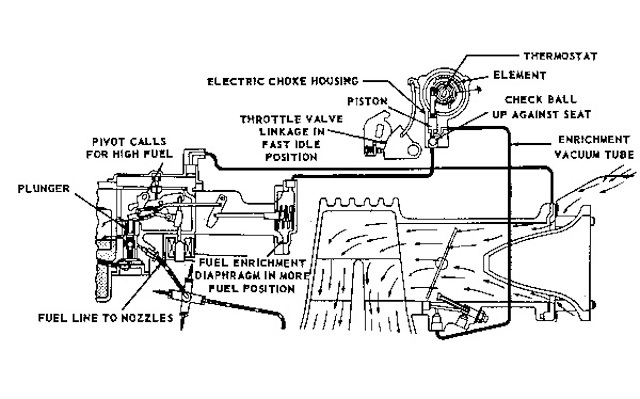

Chevy’s Ramjet was rather difficult and complicated involving directing inducted engine-air across a spoon-shaped plunger that moved in proportion to the air volume. The plunger connected to the fuel metering system which mechanically dispensed fuel to the cylinders through individual distribution tubes. While touted as mechanical injection, the Ramjet was mainly vacuum operated.

Chevy’s Ramjet was rather difficult and complicated involving directing inducted engine-air across a spoon-shaped plunger that moved in proportion to the air volume. The plunger connected to the fuel metering system which mechanically dispensed fuel to the cylinders through individual distribution tubes. While touted as mechanical injection, the Ramjet was mainly vacuum operated.

As the appropriate vacuum signals are created in the throttle body (by running the air through a venturi), the vacuum signal corresponds mathematically to the flow of air entering the engine. This carefully calculated vacuum signal activates the diaphragms in the fuel meter, which in turn activates the movable pivot and lever assembly, moving the spill plunger. This allows the mathematically calculated amount of fuel to reach the injectors.

Basically, here’s how it worked:

- A high airflow/high vacuum signal raises the linkage, but lowers the spill plunger. This shuts off the spill port, raising injection pressure and enriches the mixture.

- A low airflow/low vacuum signal lowers the linkage but raises the spill plunger. This opens the spill port, bleeding off injector pressure and leaning out the mixture.

- At idle, the air meter vacuum signal is very weak. This allows the control diaphragm to drop, consequently opening the spill port all the way, sending most of the fuel back into the float bowl.

Although this system was not a “pulse” or intermittent injection, it was a constant flow system, metering fuel to all cylinders simultaneously from a central “spider” of injection lines. The internal fuel meter adjusted the amount of flow according to engine load and rpm, and included a fuel reservoir, which was similar to a carburetor’s float chamber. The Rochester featured “port” injection, meaning the injectors are located in the intake manifold near the intake valve.

Although this system was not a “pulse” or intermittent injection, it was a constant flow system, metering fuel to all cylinders simultaneously from a central “spider” of injection lines. The internal fuel meter adjusted the amount of flow according to engine load and rpm, and included a fuel reservoir, which was similar to a carburetor’s float chamber. The Rochester featured “port” injection, meaning the injectors are located in the intake manifold near the intake valve.

As Chevrolet introduced the Rochester Ramjet as optional equipment for the ’57 Corvette, it was also made available for the 1957 Pontiac Bonneville. Although the Rochester system was not too popular with the general public, it did engender quite a bit of notoriety for pushing the V8 Corvette over the one-horsepower-to-one-cubic-inch barrier, which only Chrysler’s Hemi engines had achieved until then. Making 290 horsepower from a 283 cubic-inch small block, the lightweight domestic roadster impressed those willing to put their foot into it.

Although the “Fuelie” option was dropped on all vehicles after 1959, that is, except for the Corvette, which used it as an option until 1965. The Beach Boys sang about their fuel injected Stingray in a handful of songs and drag strips welcomed the fiberglass bodied exotic sports cars. The problem, it seemed, wasn’t with the injection system itself, but rather the stigma that surrounded it.

Enthusiasts and historians note that the Rochester’s demise was due to two key (and costly) elements: the complicated matter in which it operated and its difficulty in troubleshooting and repairing. Retraining and educating current mechanics at dealerships was a costly affair and many “wrenches” didn’t take well to the experimental intake.

Beaten to the punch but not to be outdone, Chrysler teamed with Bendix to make the Electrojector fuel injection systems for their 1958 model year Chrysler 300D, Dodge D500, and DeSoto Adventurer automobiles. Chrysler engineers failed to learn from the mistakes of Chevrolet’s Rochester system and came up with an even more complex system that included two dual-point distributors; one which ran the electronically-operated fuel injection and the other the ignition.

Beaten to the punch but not to be outdone, Chrysler teamed with Bendix to make the Electrojector fuel injection systems for their 1958 model year Chrysler 300D, Dodge D500, and DeSoto Adventurer automobiles. Chrysler engineers failed to learn from the mistakes of Chevrolet’s Rochester system and came up with an even more complex system that included two dual-point distributors; one which ran the electronically-operated fuel injection and the other the ignition.

The multi-point system featured dual two-barrel throttle bodies was made available as an option on Chrysler products using both HEMI and Wedge engines. An electric fuel pump siphoned gas to the individual injectors while the system’s two electronics boxes were mounted to the car’s radiator in an effort to keep the boxes cool. One was a resistance box and the other an electronic modulator, and both used early transistors along with old style resistors and capacitors.

Bordering on science fiction technology to 1958 American mechanics, the Chevrolet system looked almost archaic in comparison. The Chrysler electronic fuel injection system was notoriously “buggy” as electronic components were tough maintain in working order nonetheless troubleshoot. Eventually, most cars sold with Chrysler’s fuel injection system were eventually retrofitted with 4-barrel carburetors as the patents for the Electrojector were sold to Bosch, who went on to develop an EFI system on the VW 1600TL in 1967.

It wouldn’t be until 1975 when GM returned to the fuel injection party with the ’76 model Cadillac Seville. The system was surprisingly – and thankfully – simple but still struggled with the woes of dated technology. Comprised of a single throttle body, eight fuel injectors mated to dual fuel rails pumping fuel into an intake manifold, a crude analog computer and an array of sensors, the new system was a joint effort between GM, Bendix, and Bosch.

It took a few years later in 1980 when the first digitally-controlled system was introduced for Cadillac. The Digital Fuel Injection (DFI) system originally conceptualized as a “multipoint injection” system was limited by its excessive production costs, but did allow for continual tuning and adjustments on the fly to the tune thanks to the computer’s ability to store “trouble codes.”

Since that time, GM’s foray into the world of fuel injection has been largely a huge success, which each year being a step in the right direction. All of which culminated in Chevrolet’s stellar LS-engine program.