Some of us just have to look good while going fast. Thankfully, there are guys like JR Granatelli of Granatelli Motor Sports who share that passion. A quick look through his company’s website shows not only a laundry list of go-fast parts, but also a wide range of appearance items that will take your ride to the next level. In fact, Granatelli Motor Sports is expanding with new CNC equipment and manpower to build these covers in the GMS Australia facility.

Currently under construction at Late Model Engines in Houston, Texas, is a new 400-cube LSX engine for the BlownZ project car. It sports a set of Edelbrock LS-R heads modified by Curtis Boggs at Race Flow Development. Unlike other LS heads, these castings are designed with an SB2 valve-cover footprint. It just so happens that Granatelli Motor Sports makes an awesome set of billet valve covers for the SB2.

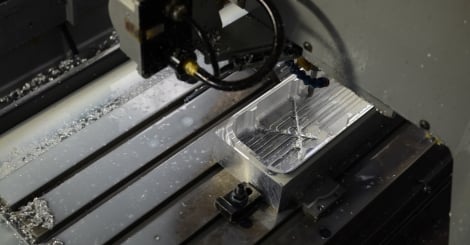

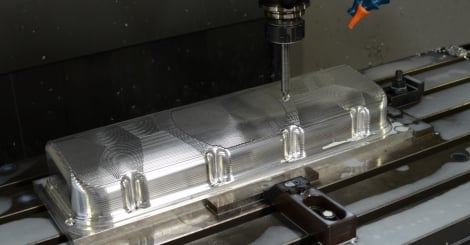

“These are constructed from 6061-T6 aluminum and are machined from a solid chunk on a CNC machine. What makes them unique is that they are machined in a single-stop process. The entire cover is shaped in one single program – it never stops. If you look at the top, or the bottom, there are no pickup marks where you can see the machine stop,” explains Granatelli.

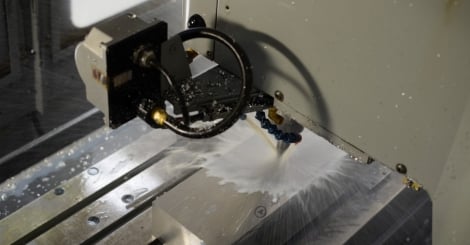

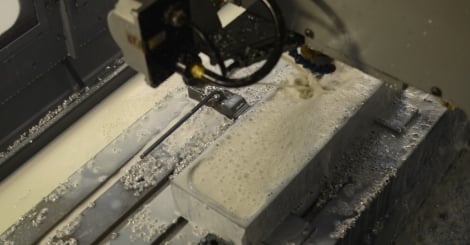

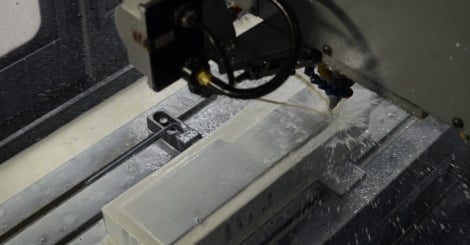

The one-stop machining process first locates all of the bolt holes, which each step of the machining process indexes from. The bottom side of the cover is scalloped out in one continuous process before the cover is flipped over to machine the top half.

The valve covers are machined in a turning center, which has the ability to do all aspects of the machining operation without a single bit of input from the operator.

“The bottom of the cover is machined first, where the bowl of the valve cover is machined out out, then the turning center flips the cover over and machines the entire top of the cover, all in one process,” Granatelli says, noting the first step of the machining process drills out the mounting holes, which are then fastened by the turning center to index all of the other machining operations. “These covers, along with the rest of our billet valve cover line, are designed in a computer program called Pro Engineering, or Pro E, before the files are exported to a Computer Aided Design file and loaded into the Haas CNC machine. From there, the machine cuts out each cover.”

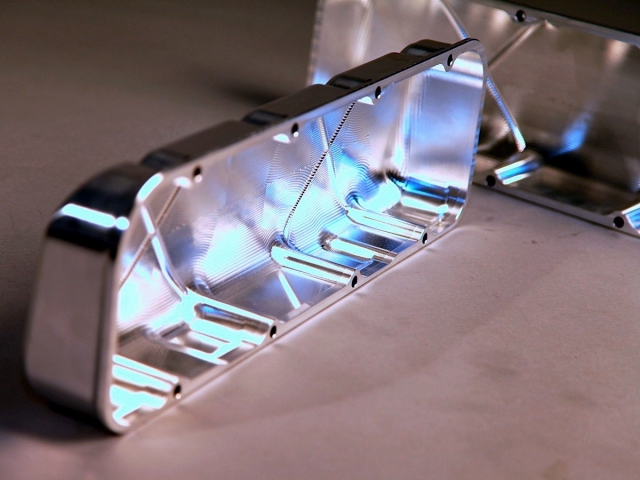

The thick gasket rail on the bottom of the covers helps to solidify the cover-to-cylinder head junction, and provides a bit of extra strength to the cylinder head casting, especially in boosted applications.

There are a number of reasons to use a billet valve cover, besides their striking good looks. These covers have optional integral valve spring oilers with removable jets, which will help to keep spring temperatures down and introduce more longevity to our package. In addition, the covers feature steel inserts in all mounting holes to reduce the chance of damage should they be overtightened, or the regular wear and tear that occurs from repeated installation and removal. Another cool feature is the ability to have a custom logo cut into the top of the cover – not a printed logo, but one actually machined into the cover’s face.

But wait, there’s more! Each cover features a set of strengthening ribs on the underside that help to prevent the tops of the covers from getting sucked down by an overzealous vacuum pump, or pushed out by an engine making tons of boost. The ribs have the added benefit of helping to keep the top of the cylinder head from flexing under boost, which will prove to be helpful in boost applications.

“The cover has the effect of an upper cylinder head stud girdle to make the cylinder head more rigid, and guys like Duttweiler and Lingenfelter are using them on all of their engines that are making big boost,” explains Granatelli.

Left - you can see the bottom side of the cover taking shape, and the strengthening ribs that are cut into the underside. Right - The top side of the cover is also finished in one continuous process - the end result is a beautiful toolpath that catches the eye from all angles.

Jewelry for your engine – and you can have them for most popular engine platforms. Check out the Granatelli website for more information!