In the realm of motorsport, every last ounce of performance you can wring out of your setup counts. A tenth can mean the difference between a podium and a pat on the back, and a healthy engine can be the deciding factor between prize money and a DNF.

In the realm of motorsport, every last ounce of performance you can wring out of your setup counts. A tenth can mean the difference between a podium and a pat on the back, and a healthy engine can be the deciding factor between prize money and a DNF.

Finding ways to improve your odds of ending up on the right side of those scenarios becomes more and more nuanced as you dig deeper into your build, but making those discoveries can have a profound effect come race weekend.

The piston ring gurus at Total Seal have a new ring design for 2016. The Total Conform piston rings feature a unique design that’s engineered to increase engine efficiency, which in turn has a positive effect on both output and fuel economy. Piston rings might not be the first mod that most builders turn to in order to unlock additional engine performance, but in this case, it’s one of those aforementioned factors that can make all the difference in competition.

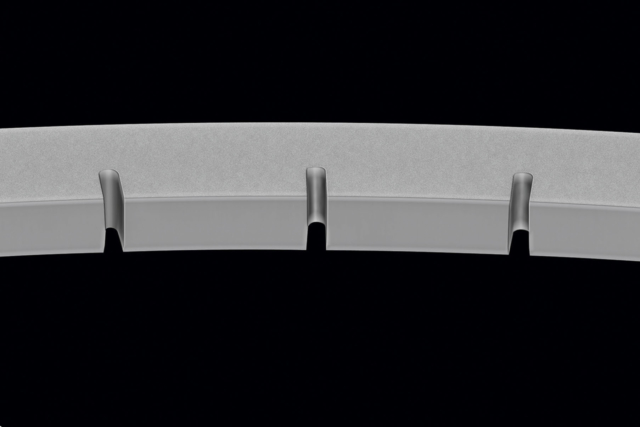

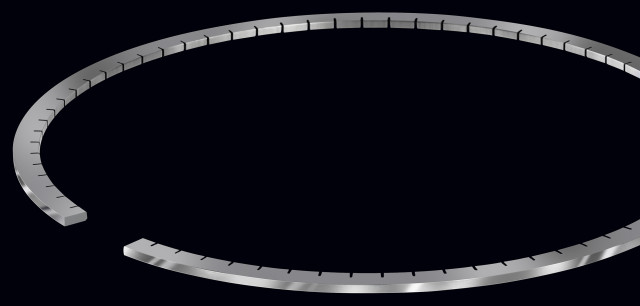

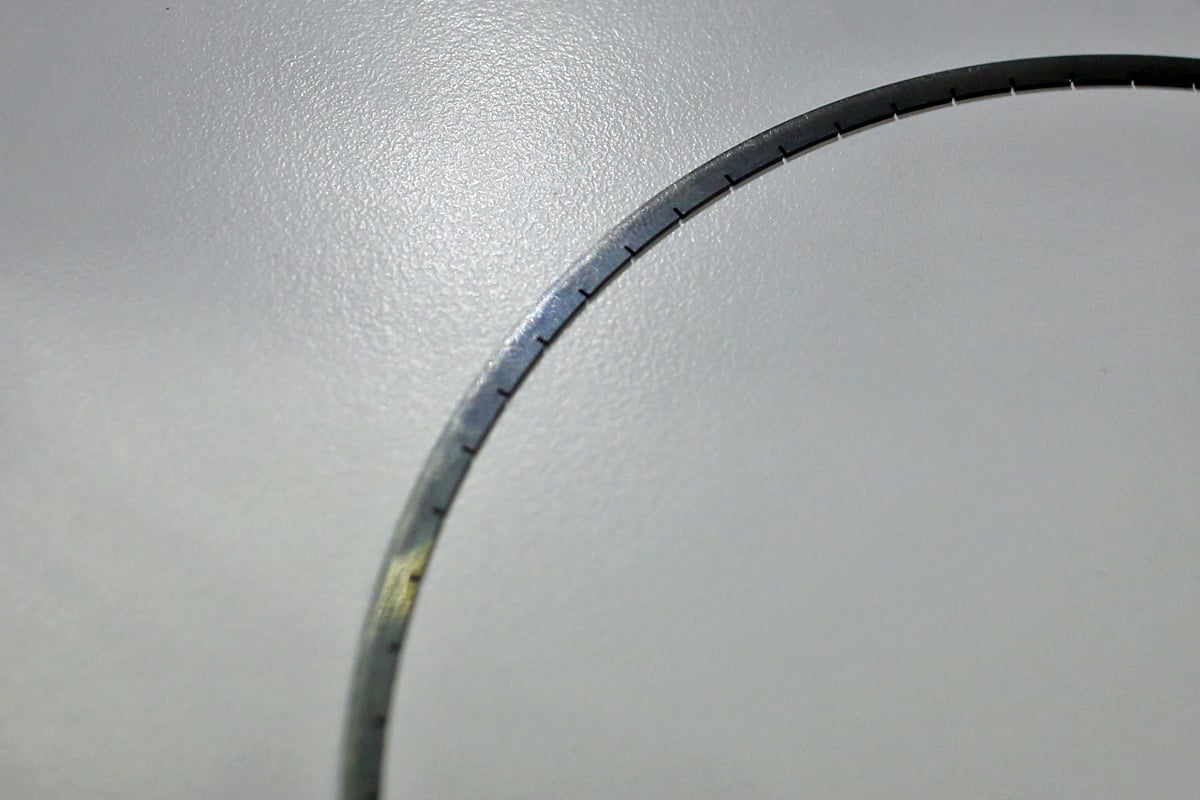

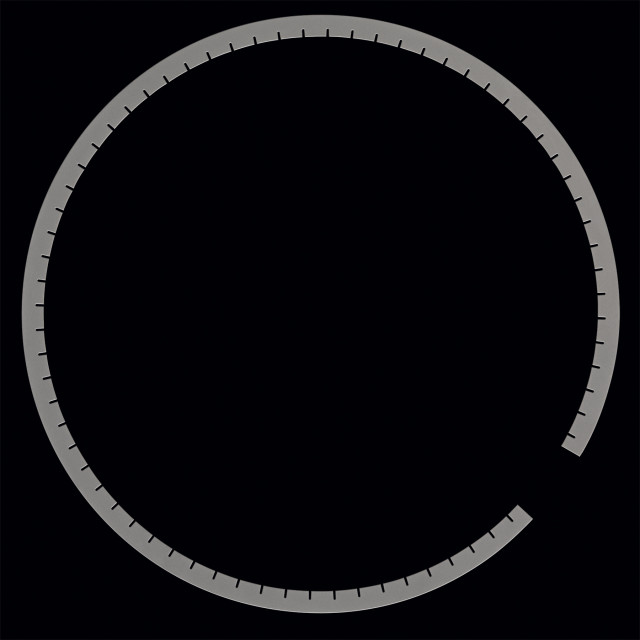

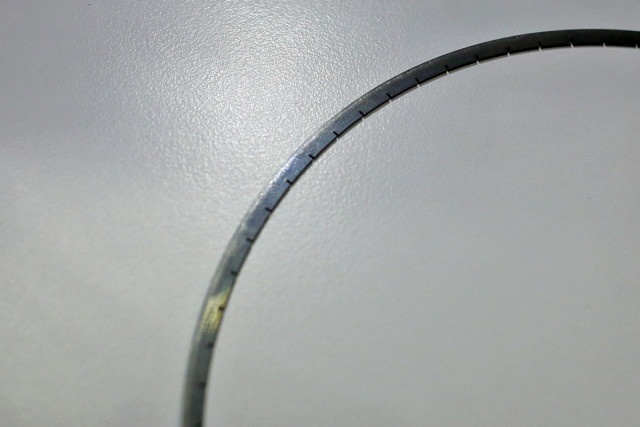

Traditional piston ring design prevents the ring from handling changes in cylinder geometry effectively. Total Seal’s Total Conform ring utilizes a series of radial notches around the inner diameter to make the ring function like as though it had a shallow radial wall ring, in turn allowing it to conform to the bore distortions while also maintaining a wide radial wall to allow it to stay firmly sealed to the piston in the ring lands. The efficiency and performance benefits from unique ring design are applicable to just about any engine build, whether it’s for a daily driven street machine or a purpose built race car.

Maximizing Efficiency

During engine operation, the piston ring face needs to remain in contact with the cylinder bore at all times. To look at a disassembled engine, that might seem like an easy task as the cylinder is round when the motor is at rest.

But once you add fuel, air and spark to the equation the inherent heat and pressure of the engine’s operation affects the geometry of the cylinder, distorting its shape. The result is that the perfect round bore seen with the motor apart has now been altered, causing imperfect geometry, and it’s the job of the piston ring to compensate for this change in geometry.

Aluminum is becoming increasingly commonplace in modern engine construction as reducing weight has become a higher priority for auto manufacturers. Jones pointed out that lighter liners have become part of that weigh saving initiative, and as engines have gotten lighter with thinner liners, distortion is becoming a bigger issue, as rings typically don’t follow bore distortion very well. That bore movement causes ring seal problems with oil, compression, and blow-by, which is where the Total Conform rings and their notched design come into play. The slotting also reduces the tension that the ring makes, and it acts as a pseudo gas port, resulting in improved loading.

Traditional piston rings have some inherent design flaws that prevent the ring from handling this change in cylinder geometry effectively. A wide radial wall ring will struggle to maintain its face contact against a non-round cylinder, resulting in blow-by and reduced efficiency. Reducing the radial wall until the ring conforms easily to the cylinder wall is an obvious solution, but this approach results in reduced piston ring to piston land contact, again diminishing efficiency and increasing blow-by.

Total Conform rings are manufactured with the faces of the rings pre-lapped so that job isn’t left to your engine. Total Seal is constantly honing lapping sleeves for use in that process. Here are some being done in the Rottler H75A honing center.

To address this issue, the Total Conform ring features a series of radial notches around the inner diameter to make the ring function like as though it had a shallow radial wall ring, in turn allowing it to conform to the bore distortions. But unlike a traditional shallow ring wall, the Total Conform ring design maintains a wide radial wall which allows it to stay firmly sealed to the piston in the ring lands.

The notches were engineered to end with a constant radius to minimize the stress, maximize the conformability, and eliminate the chance of failure from fracturing. The end result is that the Total Conform ring design solves the cylinder geometry issue faced with traditional piston ring designs without sacrificing durability to get there.

“The slots in the Total Conform piston rings allow the ring to follow the bore as it moves around,” explains Keith Jones of Total Seal. “The upshot is that the ring becomes more flexible, and keeping the ring “light tight” in the cylinder is imperative to good ring seal. The slots also reduce the friction the ring generates as well as well as helps to improve gas loading.”

The Total Conform slots allow the ring to follow the bore as it moves around, thus allowing the ring to be more more flexible and keep the ring “light tight” in the cylinder, which is a key aspect to good ring seal. The slots also reduce the friction the ring generates and help to improve gas loading characteristics.

Unlocking Potential

To perfect the Total Conform design while waiting for the patent process to complete, Total Seal spent a lot of time fine tuning in real-world testing situations in Sprint car and a Pro Stock car racing. “We did a lot of testing to make sure that it could handle the level of abuse it would see in a racing environment,” Jones adds.

Here the AP stainless steel ring goes from raw material to coiled product. Tension, drag, and stress are all important characteristics for piston rings, but no other factor influences ring performance more than the shaping of the ring during the manufacturing process.

“Modeling was done on our in house system during the design phase but ultimately we did a lot of real-world testing, because that’s where you really discover how to dial it in.”

In most scenarios that I can think of there is nothing but improved performance to be had. Better ring seal and lower friction – there’s really no down side to that. –Keith Jones, Total Seal

In terms of the sizing and construction material used with Total Conform rings, Jones says that’s often determined on a case by case basis. “We use different grades of steel to manufacture from. The material is chosen based on the end user’s application and how much heat the part has to contend with. Ring size, material and gap are all about the running environment it’s used in – how much heat that part will have to handle and for what period of time. This is a big part of why we want that direct communication with the builder so we can discuss in detail what they are using this engine for and their expectations from it. This helps to eliminate the guess work that may come in to play.”

The notches in Total Conform rings were engineered to end with a constant radius to minimize the stress, maximize the conformability, and eliminate the chance of failure from fracturing. Along with computer modeling done in their in-house system during the design phase, Total Seal torture tested these rings extensively in Sprint car and a Pro Stock car racing.

Wide Application Scope

While the Total Conform rings provide a competitive edge for motorsport applications, they also yield benefits in more conventional builds as well. OEM vehicle testing has shown improvements in fuel economy, horsepower and torque while also increasing crankcase volume as well, making these rings a great upgrade for street car builds as well as more extreme builds tailored for racing use.

The notches in the Total Conform rings have a radius which eliminates stress risers rather than a square cut. This makes the ring more “conformable”. These rings also provide benefits from lower friction, less tension, reduced mass, and improved crankcase vacuum, in turn yielding improved engine output as well as better fuel economy.

“The Total Conform ring design is driven by our never-ending quest to increase ring seal while at the same time reduce friction in a vast array of applications,” says Jones. “We put the design through rigorous testing in harshest of environments – professional racing – to make sure it performed how we wanted it to. The result is that Total Conform rings apply to just about all applications.”