There comes a time when bolt-on modifications become obsolete and the craving for more power grows. For Project Storm Trooper [2], our 2005 GMC Canyon, that time came with the change in direction for the project – keep it as a streetable truck or turn it into an off-road race vehicle. The decision came easy, and the project was to take a whole new look, but it would need a different tune to it. The truck needed to have the bite to match the aggressive stance.

LT376/535 Engine Specs

Part Number: 19355378 [4]

Engine Type: Gen-V Small-Block V-8

Displacement (cu. in./liters): 376/6.2

Bore x Stroke (in.): 4.062 x 3.622 (103.25 x 92 mm)

Block: Cast aluminum with six-bolt, cross-bolted main caps

Crankshaft: Forged steel

Connecting Rods: Forged powdered metal with specific machining

Pistons: Hypereutectic aluminum

Camshaft Type: Hydraulic roller (billet steel)

Valve Lift (in.): 0.577” intake / 0.577” exhaust

Camshaft Duration (@0.050 in.): 228° intake / 248° exhaust

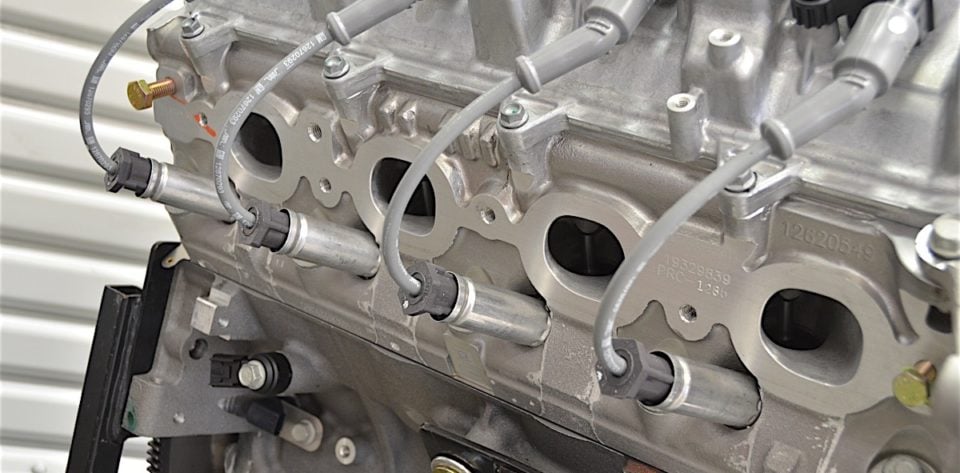

Cylinder Heads: Cast aluminum; CNC-ported with 58 cc chambers

Valve Size (in): 2.13 intake / 1.59 exhaust

Compression Ratio: 11.5:1

Required Fuel: Premium

Maximum Recommended rpm: 6600

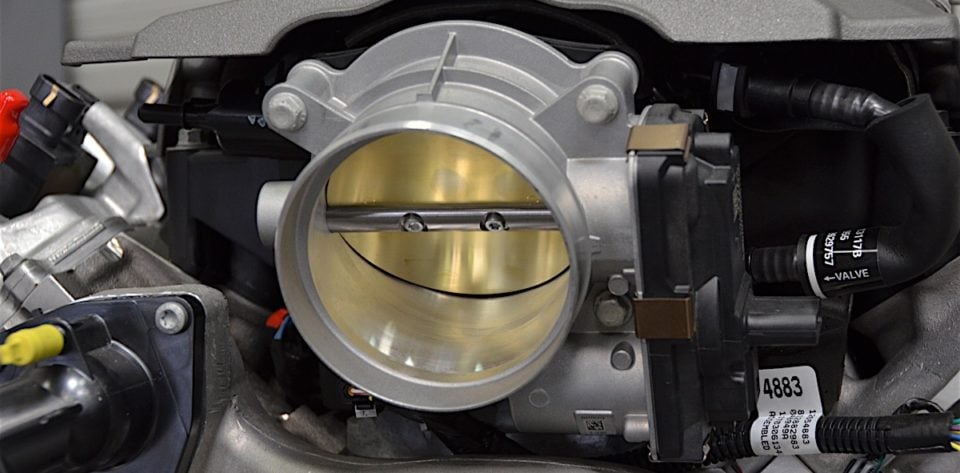

But we did not go with just any LT1. Instead, we went for Chevrolet Performance [5]’s LT376/535 and its Connect & Cruise package with the SuperMatic 4L75E. The LT376/535 retains the technology of the Gen V LT1, but adds CNC-ported heads and Chevy’s high-lift LT1 hot cam. At 6.2 liters and 376 cubic inches, this engine is rated at 535 horsepower and 470 lb-ft of torque.

The LS platform is a popular motor in off-road applications, and the direct-injected LT1 is gaining steam as more people become familiar with it. A lot goes into a swap like this (let alone the application), but we are going to walk you through all of the steps.

Whether or not you are into off-road applications, we will be sure to show the process the same way as if you were tossing it into a classic. Let’s take a closer look at everything that is going on under the hood.

Swapping In A New Heart

Just like any other engine swap, a project like this took plenty of planning. Without planning, making sure everything worked together could get tricky. One of the biggest changes to GM’s new line of engines and vehicles was electric steering.

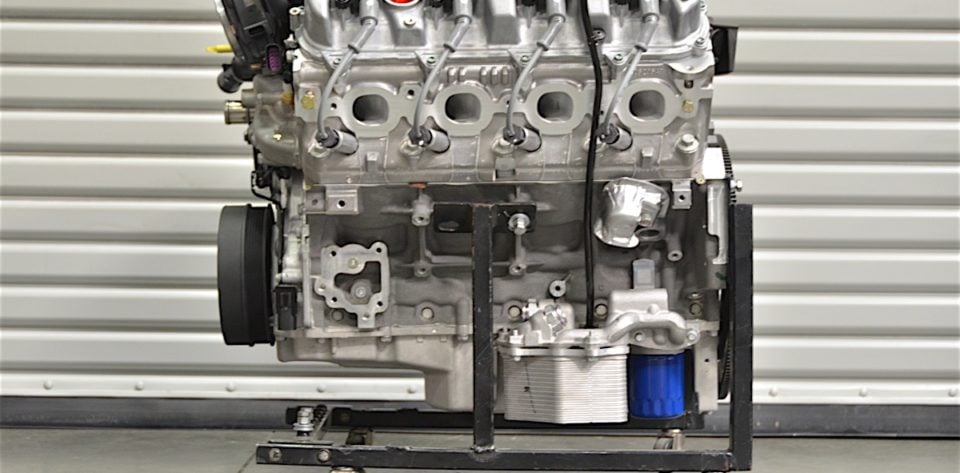

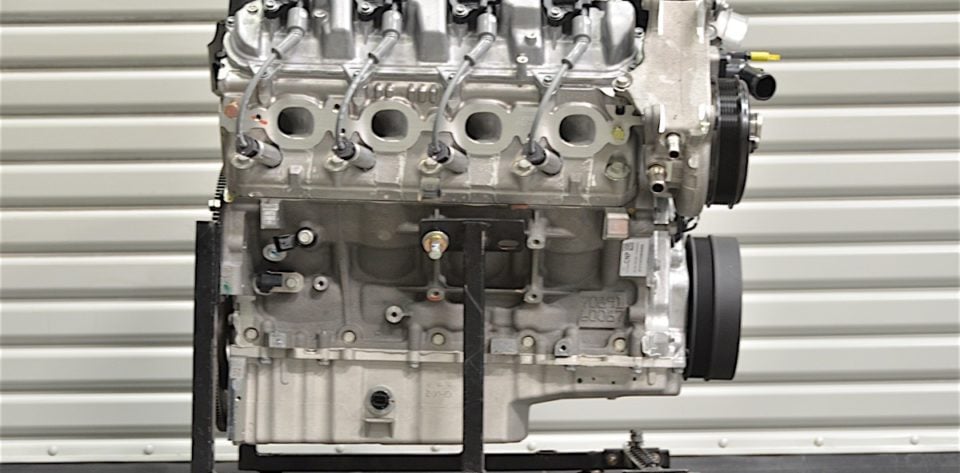

Chevy's all-new LT376/535 is a piece of art. The engine looked great on the stand, and we couldn't wait to get it under the hood.

This would be the first part to tackle in the project, since we were planning on keeping the factory rack and pinion. Because of this, the front end accessory drive (FEAD) needed to be removed.

For the project, we decided to go with an ICT Billet [11] accessory kit that used the L83 (basically the truck version of the LT1) water pump, tensioner, truck damper, and alternator. We decided to stick with the factory L83 water pump, but decided to go with an ATI Performance Products [12] damper, Powermaster [13] alternator, and Turn One [14] power steering pump.

Swapping from electric steering to power steering meant that the factory FEAD on the LT376 needed to be removed. With the help of ICT Billet, we got our Turn One power steering pump on the engine.

In addition, we chose C&R Racing [19] for the radiator, Derale Performance [20] for the external oil coolers, Racepak [21] for the gauges, Wilwood [22] for new master cylinders and brake pedal, Current Performance Wiring [23] for motor mounts, and Holley [24] for the fuel system. We are still in the planning stages for the headers and exhaust.

The truck’s going to be getting a complete makeover, not just the engine swap. We are installing a custom race-legal roll cage, Mastercraft Safety [25] 3G suspension seats, Impact Safety [26] harnesses, and a McNeil Racing [27] fiberglass dash. We will be busy with plenty of work, but were looking forward to the finished project.

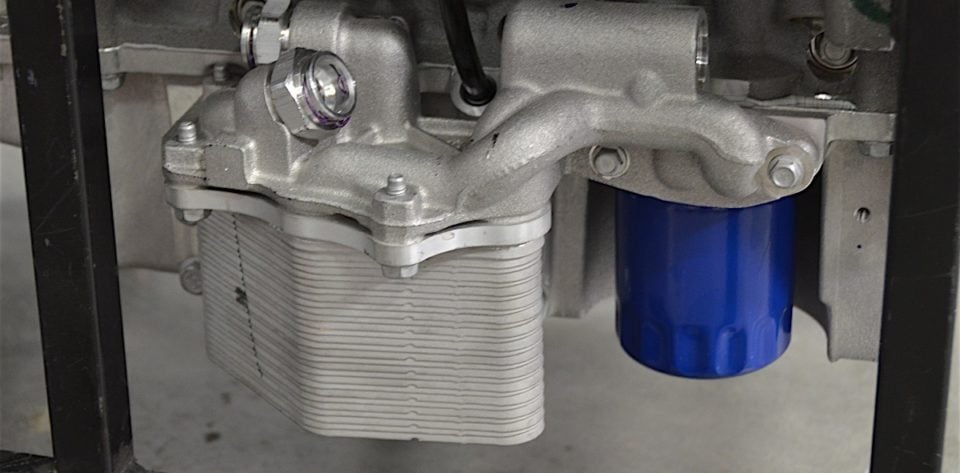

Up close, you can see the CNC ported heads. The factory damper and engine oil cooler will both be removed by the time this swap is over.

So much goes into a swap like this, and even though there are a lot of moving parts, we can’t wait to turn the key (if we still have one when we are done) and hear the roar of the engine. In the end, we’ll need to learn how to drive it all over again.

What Is Next

The goal for the truck is to be completed by November 2017, do some testing in December, and prepare for its first race in January at the MORE Racing [33] SlashX Duel In The Desert in Barstow, California.

Along the way, we will showcase the pre-install and engine preparation, the Connect & Cruise kit, fuel system, cooling system, the 4L75E, and of course, the performance review on the dyno and in the desert.

The LT376/535 is just the start of this project. Be sure to keep checking back for updates!

Be sure to keep checking back, as this is going to be one incredible project you don’t want to miss. For more information on Chevrolet Performance’s products, be sure to check out its website [5].

What do you think of the swap? What do you want a closer look at? Is there anything you want to see us do? Tell us in the comments below!