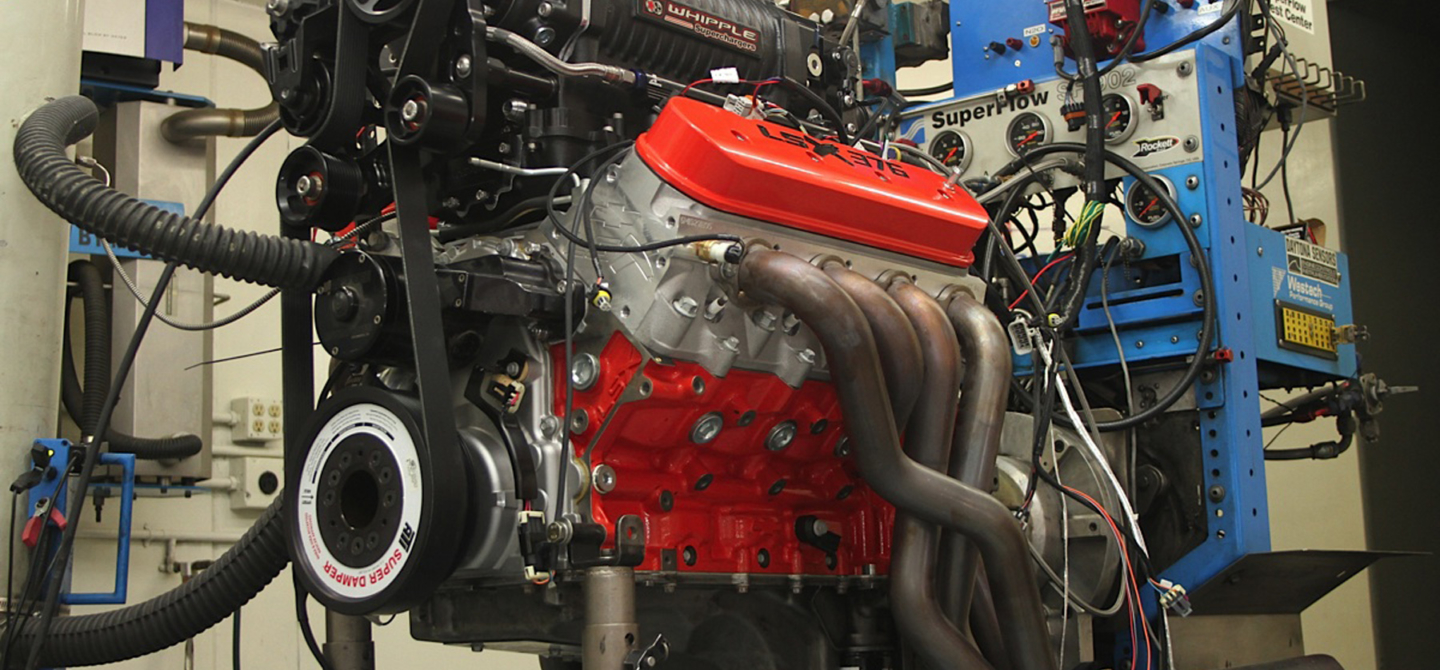

In our previous installments, we set out on our quest to coax a thousand horsepower out of Chevrolet Performance‘s LSX376-B15 long block. In part one, we gave you a detailed look at what goes into these stout engines at the factory, and in part two, we topped our engine with a 4.5L Whipple supercharger and put it through its paces on the engine dyno at Westech Performance.

The end result of our first day of testing was a peak of 1,025.4 horsepower and 884.7 foot-pounds of torque with 24 pounds of boost, using a 4-inch diameter supercharger pulley, the smallest we had. Using stock, off-the-shelf components from Chevrolet Performance and Whipple, we’d put together a combination that could crank out four-digit horsepower. But we knew the engine could make even more power and torque, with less manifold pressure, if we swapped the production-spec cam supplied with our LSX376 for one better suited to our gigantic blower.

After our original testing, we came back to Westech to swap cams and see what a more aggressive spec would provide in terms of power.

Room for Improvement

Chevy Performance positions the “B-line” LSX376 engines as their boost-ready crate motors, but the LSX376-B15 ships with the stock LS7 camshaft installed rather than the one from the LSA or LS9, the company’s supercharged production engines. Here’s how the specs compare:

LS7 – Part Number 12638426

Camshaft Duration at 0.050-inch lift: 211 intake, 230 exhaust

Valve Lift: .558 intake, .558 exhaust

Lobe Separation Angle: 121 degrees

LSA – Part Number 12623064

Camshaft Duration at 0.050-inch lift: 198 intake, 216 exhaust

Valve Lift: .480 intake, .480 exhaust

Lobe Separation Angle: 122.5 degrees

LS9 – Part Number 12638427

Camshaft Duration at 0.050-inch lift: 211 intake, 230 exhaust

Valve Lift: .562 intake, .562 exhaust

Lobe Separation Angle: 122.5 degrees

Browsing the Chevy Performance catalog and comparing specs, it’s easy to see why the LS7 cam got the nod for duty in the LSX376-B15. While they offer other cams with more aggressive lift and duration, they all have one feature in common that makes them less-than-ideal candidates for blower duty – relatively narrow lobe separation angles.

A narrow angle offers a performance advantage in naturally-aspirated engines in that they like having a certain amount of valve overlap, the period of time when both the intake and exhaust are open. This helps cylinder scavenging and volumetric efficiency when all you have to work with are exhaust and atmospheric pressure to move gasses in and out of the cylinder.

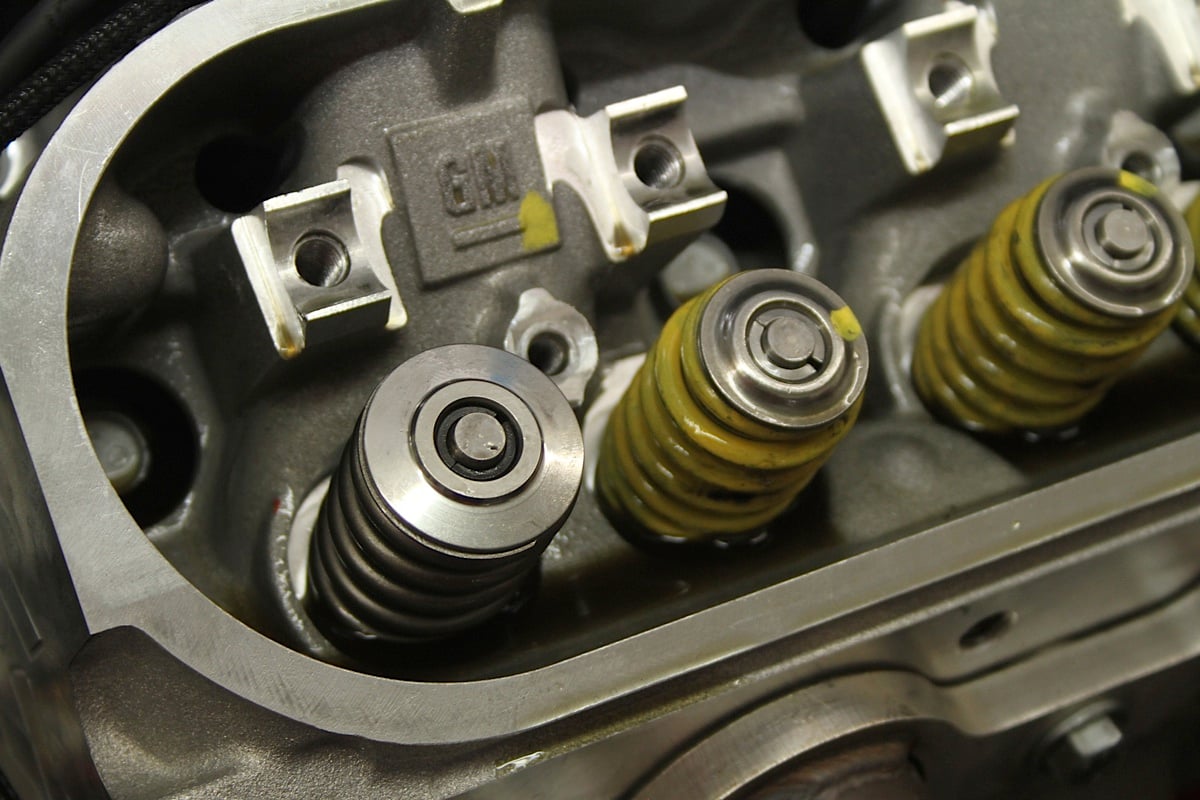

At Crane's recommendation, we also switched out the stock valve springs for dual Crane springs and titanium retainers.

Supercharged engines are a different animal, though. With positive pressure available on the intake side, too much overlap just means the extra fresh air and fuel end up getting shoved out the exhaust port instead of sticking around where they’ll do some good, so a wider angle is generally a good idea. Generally speaking, cams for supercharger applications also don’t need as much duration on the intake side, while they need relatively more on the exhaust side because of the over-100-percent VE they achieve.

When you take a look at the Chevy Performance cam specs, only three on the list have a lobe separation angle of more than 120 degrees – the LSA and LS9 sticks, and the LS7. Everything else has an angle in the 107-118 degree range. Comparing the LS7 and LS9 cams, the specs are very, very similar – the same duration on both intake and exhaust at 0.050 lift, with a tiny bit more valve lift for the LS9 (just .004 inches – not enough to make a real difference) but 1.5 degrees less lobe separation angle.

A Compromise is Struck

So why pick the LS7 over the LS9 spec for the cam? We can’t say for sure, but we’d guess it has to do with marketing, at least in part. Stay with us here, because this is speculation on our part, but the decision to go with the LS7 may have stemmed from a desire to give the LSX376 a bit more oomph when naturally aspirated, compared to the numbers they’d get with the LS9 cam. You see, Chevy couldn’t very well put these crate engines into the lineup without having SOME horsepower and torque number to publish, but the engine ships as a long block, not as a complete ready to run package.

To quote the Chevy Performance catalog, “Horsepower and torque were derived by GM Engineering using a normally aspirated LSX376 with LS3 EFI. Your power numbers may vary, based on induction system and componentry.” In other words, 450 horsepower at 5,900 RPM and 444 pound-feet at 4,600, the quoted power and torque for both the -B8 and -B15, is not representative of how any of these engines will actually be configured by the customers who buy them.

So, they ship with a camshaft that is a compromise selection that keeps the N/A numbers from looking lazy, but also won’t be too much of a handicap if the end user decides to keep it when they do the blower install. Clearly, since we managed to surpass 1,000 horsepower with the stock cam installed, it’s not completely necessary to replace it, but we wanted to see how much power we were leaving on the table.

Crane Technique

To get ourselves a bumpstick spec’ed to work a bit better with our big Whipple supercharger, we called up Chase Knight at Crane Cams. Knight has been working for Crane for more than four decades, and his camshaft wisdom is unsurpassed.

We provided him with the complete details on our combination, and asked for a demonstration of his True Kung Fu in cam selection. Here’s what he recommended:

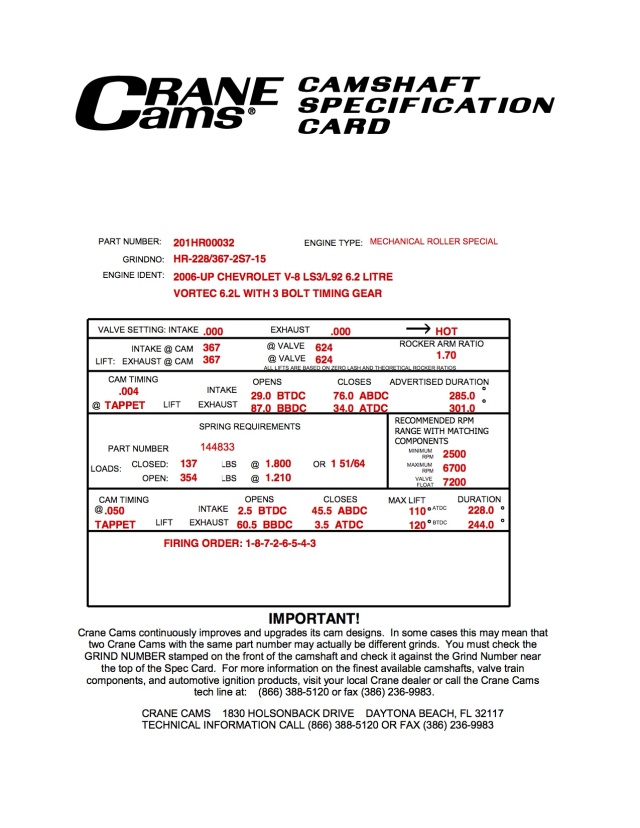

Crane Cams Part Number 201HR00032

Grind Number: HR-228/367-2S7-15

Camshaft Duration at 0.050-inch lift: 228 intake, 244 exhaust

Valve Lift: .624 intake, .624 exhaust

Lobe Separation Angle: 115 degrees

Per Knight, this cam is a direct drop-in replacement for our stock piece, despite having more peak lift on both the intake and exhaust valves. “We have used this in supercharged LS3 applications without any piston-to-valve issues,” he explains.

We also installed Crane’s Pro Series One Piece Pushrods (PN 144621-16 for a full set). These 5/16-inch pushrods are made from 0.080 wall 4130 steel tubing for light weight and strength. They’re heat treated for use with or without guide plates.

Dat Overlap

We asked Knight about our preconceptions about overlap and supercharged powerplants, and got an education on how boost and valve timing interact. “Assuming no advance, both [the LS7 cam and the new Crane cam] will have similar intake closing and exhaust opening figures,” Knight adds. “With no cam advance, the GM cam intake opens [to 0.050 lift] 15.5 degrees after top dead center, and closes 46.5 degrees after bottom dead center; the exhaust opens 56 degrees before bottom dead center, and closes 6 degrees before bottom dead center.”

For this test series we left both cams installed “straight up,” so for comparison, the new Crane unit opens the intake (again to 0.050 lift) 2.5 degrees before top dead center, closing at 45.5 degrees after bottom dead center, while on the exhaust side the valve opens at 60.5 degrees before bottom dead center, and closes 3.5 degrees after top dead center.

Per Knight, “The overlap figure changes greatly, from -21.5 degrees with the stock camshaft [no real overlap at all], to 6 degrees with the Crane piece. The similar intake closings will create similar cranking compression figures, providing reasonable throttle response.” But wait – didn’t we just say that supercharged engines didn’t like overlap?

Idle quality (and vacuum) will probably be reduced a bit, but the increased low RPM boost should help compensate for that. – Chase Knight, Crane Cams

Of course, there’s no such thing as a free lunch – Knight notes, “Idle quality (and vacuum) will probably be reduced a bit, but the increased low RPM boost should help compensate for that.” Needless to say, idle quality isn’t a primary goal here either.

Besides raw lift and duration numbers, Crane also builds power by taking advantage of the LS engine’s relatively low-inertia valvetrain with the shape of their lobes. More aggressive opening and closing rates than stock factory cam profiles put more area “under the curve” and reduce the amount of time spent at low lift. “The GM lobe designs are intended for long term durability, while most performance aftermarket offerings aren’t overly concerned with 100,000 mile life,” Knight admits.

Meanwhile, at Westech…

Once again, we went back to Westech Performance, where dyno expert Steve Brulé and his staff were ready to perform the cam swap and run our LSX376 again. In addition to the camshaft itself, Crane also provided new valve springs, spring seats, stem seals, locks, and titanium retainers, as well as new pushrods. In a matter of just a few minutes, they’d changed out the stock components for the Crane valvetrain gear, and reinstalled the 5-inch diameter “low boost” pulley on our 4.5-liter Whipple supercharger.

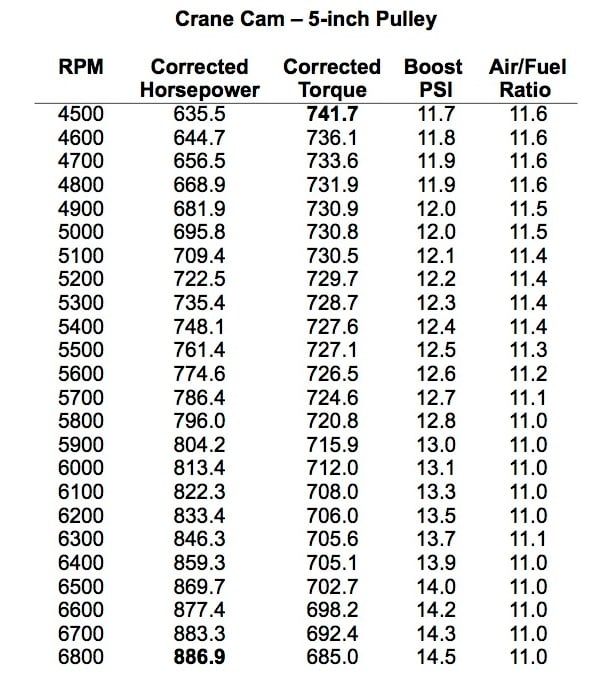

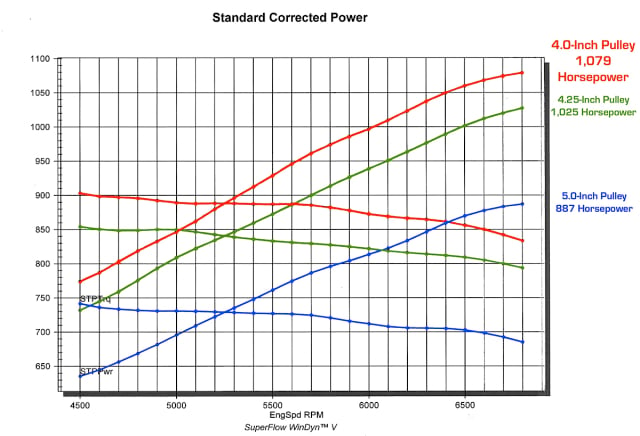

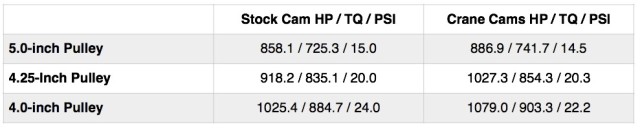

For reference, when we dynoed the engine with the stock cam and 5-inch pulley, our peak numbers were 858.1 horsepower and 725.3 pound-feet of torque, with a max of 15 PSI boost. With the new Crane bumpstick and the same pulley, we were rewarded with a max of 886.9 horsepower and 741.7 pound-feet, increases of 27.9 and 16.4, respectively. We also saw slightly less boost, at a peak of 14.5 PSI, evidence that air was moving more efficiently through the engine thanks to the new camshaft.

Once again, it’s worth mentioning that our dyno graphs start at a relatively high 4,500 RPM for a reason – as we noted in the previous article, this engine makes so much torque at low RPM that the engine dyno simply can’t hold it low in the rev range at full throttle. Even with the brake at 100% servo, the engine simply pulls through. To keep results consistent, we chose the starting point for all our data as 4,500 RPM, but a glance at the graphs shows that the true peak torque this combination produces happens before that point, and is higher than our reported number.

Stepping Down to Step Up

With our initial pull with the new cam showing promise, we switched to the smaller 4.25-inch diameter supercharger pulley to increase the step-up ratio and turn the blower faster. You may recall from our previous installment that we cut the stock cam 4.25-inch test short at just 6,000 RPM, since it was clear that we weren’t going to hit our thousand horsepower goal with that particular pulley.

Even cutting things short by 800 RPM still achieved 918.2 peak horsepower at the top, and 830-plus pound feet of peak torque down at the 4,500 RPM starting point of the pull on the stock-cam combination. Max boost climbed to 20 PSI, showing that the engine was starting to bottleneck.

With the new cam in place, the torque we saw at 4,500 RPM jumped to 854.3 pound-feet, and as the engine climbed to 6,000, we saw 938.7 horsepower, beating the stock cam by 20.5 horsepower and doing it with just 18.6 PSI. By 6,500 RPM, we had broken through the thousand-horse barrier, and at the 6,800 RPM redline we recorded 1,027.3 horsepower and 20.3 pounds of boost.

For reference, that’s almost 2 horsepower more than what we topped out at on our previous stock cam test with the smaller 4-inch pulley, with four fewer pounds of boost. Not bad, but we weren’t done yet…

Max Effort

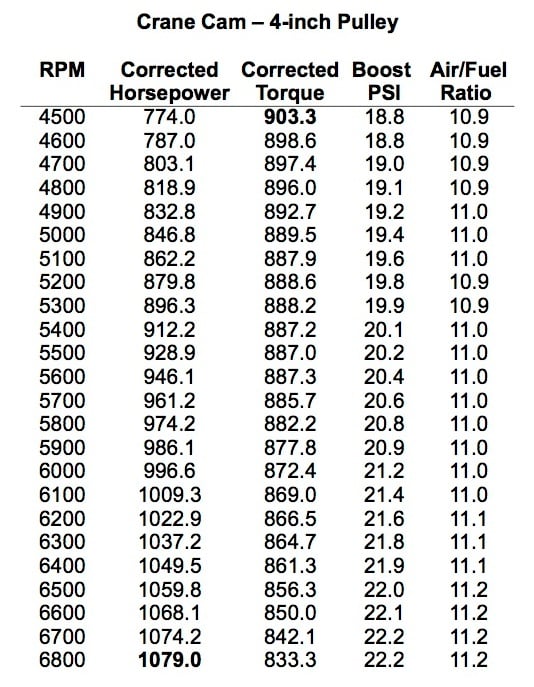

For our final test, Brulé swapped on the 4-inch pulley and fired up our LSX376 once more. With the stock camshaft, we topped out at 1,025.4 horsepower and 884.7 pound-feet. We’d already eclipsed that horsepower mark with the cammed-up motor using the 4.25-inch pulley, and as soon as the pull started, we had a new peak torque figure of 903.3 pound-feet at 4,500 RPM.

The LSX376 roared and the Whipple whined, ripping up through the rev band once more to 6,800 RPM. There, we plotted a peak of 1,079.0 horsepower and just 22.2 PSI of boost, with the torque figure gently dipping down to “only” 833.3 pound-feet at redline. That gave us a gain of 53.6 horsepower peak-to-peak with the smallest pulley, at lower boost. That lower boost number is important, because as we explained last time around, it’s really a measure of restriction between the blower outlet and the combustion chamber. We made more power with less work required from the supercharger thanks to the free-flowing Crane Cam.

What’s Next?

Now that we have our LSX376-B15 dialed in, we need to find a home for it and see how it drives. Stay tuned as we take this Whipple-whipped boost monster from the dyno to the street!