[1]The driveshaft is one aspect of a car that’s usually overlooked and taken for granted. We might add a driveshaft loop to comply with track regulations, but after that we rarely think about the driveshaft. However, there is a lot more to consider when it comes to driveshafts than just shoving a metal pipe under your ride.

[1]The driveshaft is one aspect of a car that’s usually overlooked and taken for granted. We might add a driveshaft loop to comply with track regulations, but after that we rarely think about the driveshaft. However, there is a lot more to consider when it comes to driveshafts than just shoving a metal pipe under your ride.

On Project Blank Slate [2], we are in the final push to get this car on the dyno. When standing under the car we have all the hard parts needed to make that happen: wheels, suspension, motor, transmission, rearend, but no driveshaft to connect and put the power to the ground. Since Blank Slate already has a Strange Engineering [3] rearend, the perfect driveshaft would be from Strange as well.

Shaft Ordering 101

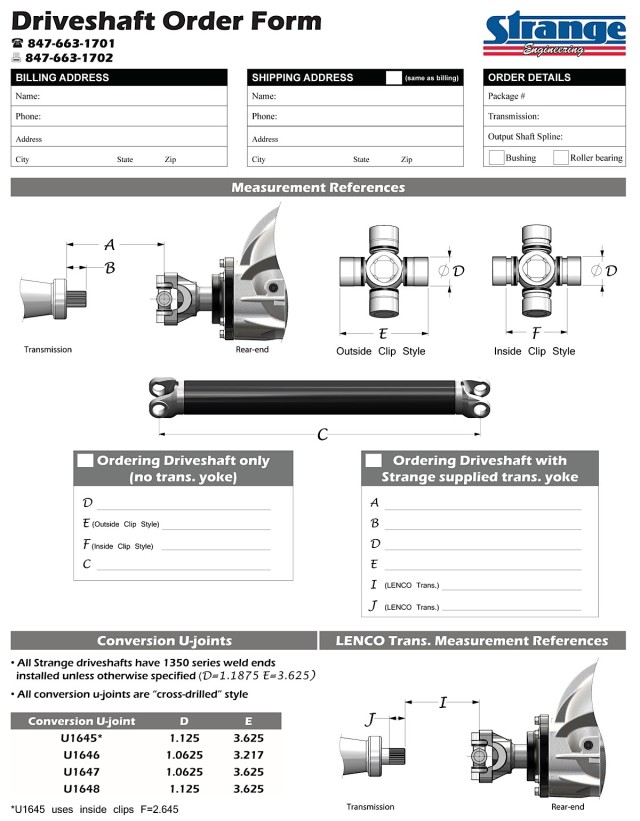

We called Strange Engineering and caught up with J.C. Cascio, who gave us all the details needed to order up a custom driveshaft. To start, he sent us a driveshaft order form, which covers all the required dimensions. These dimensions are easy to measure with a basic tape measure. To start we made sure the car was sitting on the ground with weight on the tires. Then we measured from the transmission output shaft seal to the middle of the yoke on the rearend. A few other measurements, such as the yoke size on the rearend and we were done.

From there J.C. had some more questions for us, “The first thing we always cover is the application: How heavy is the car? How much horsepower? How much RPM will the motor spin?” All these are factors needed, along with the measurements, in order to get the right shaft for the job.

Strange Engineering offers three different styles of driveshafts, all of which are constructed from chrome-moly. The first variation is three inches in diameter with spicer weld ends. The second is also three inches in diameter, but with forged Strange Engineering chrome-moly weld ends. The last style is the strongest version with a three and a half inch diameter tubing with forged Strange Engineering chrome-moly weld ends.

“Whipping is the technical term for when a driveshaft loses shape” J.C. Cascio – Strange Engineering

The two biggest factors in a driveshaft reaching critical speed are the length and RPM. Even if a car has a low horsepower motor, but the driveshaft is super long and spins a high RPM, it will reach critical speed. Torsional strength won’t factor in, the length is the true killer.

“The shorter the shaft, the less prone the driveshaft is to whipping. Whipping is the technical term for when a driveshaft loses shape,” continued Cascio.

With our 750 hp LME 502ci LS engine, we knew there would be tons of power going through the shaft. Having a redline close to 7,000 rpm, we knew that shaft would be spinning faster than a tornado as well. We wanted to make sure that we could put the pedal to the metal and not worry about the driveshaft failing on us.

One Size Doesn’t Fit All

“The first thing we always cover is the application: how heavy is the car, how much horsepower is the car going to make, what kind of RPM the motor is going to spin at, and of course the length of the driveshaft factors in,” stated Cascio. Once Strange has all that information, they can then build you a driveshaft. They have three different options for driveshafts, based on the requirements:

1. Three-inch chrome-moly driveshaft with Spicer weld ends

2. Three-inch chrome-moly driveshaft with forged Strange Engineering chrome-moly weld ends

3. Three and a half-inch chrome-moly driveshaft with forged Strange Engineering chrome-moly weld ends

With the needs of our driveshaft, a three-inch chrome-moly driveshaft with forged Strange Engineering chrome-moly weld ends would work perfectly. Even though this is a completely custom made driveshaft based off our specs and requirements, the average wait time is only a week, to a week and a half. Every single driveshaft is made to order and will have that small lead time.

After waiting about a week, our driveshaft showed up. Installation was a breeze as we slide the input shaft into the transmission. We did have to stop and adjust our driveshaft loop, but that’s only two bolts. With the front end in the transmission, we put the rear of the driveshaft into the rearend. With two U-joint bolts, the installation was done. The shaft’s length was perfect, with no modifications needed.

Stay tuned as we put the finishing touches on this motor to get the car on the dyno!