When you’re dealing with a quick and fast street car that’s being called upon to manage stop-and-go driving while getting you to and from the race track, and bring you to a safe stop from 150 mph or more on the 1/4-mile, just any old brake system won’t suffice.

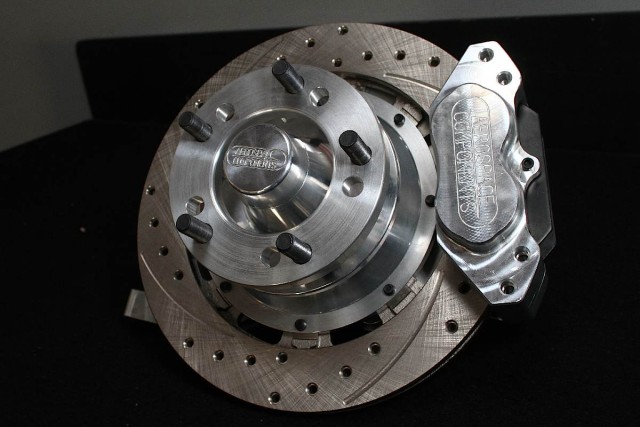

Our complete Aerospace Pro Street brake kit features a front kit that’s compatible with the stock 2010-14 Camaro spindle and hub. The rear, meanwhile, is a standard axle and housing flange setup.

As anyone with an understanding of friction will concur, brake rotors can become particularly hot through repetitive use in traffic, and as such, passenger car brakes are designed not only to stop you safely, but also to minimize heat. On the opposite end of the spectrum, drag racing-specific brake systems use relatively simple, lightweight rotors intended for singular (but aggressive) applications of the brakes from a high rate of speed, where they get really hot for a short period of time, and then are allowed to cool for perhaps several hours thereafter.

For street and strip vehicles, developing an adequate brake system for all situations is a delicate balance of blending the attributes of street and race brake packages to minimize heat and fade, deliver impressive braking power, and come in at a lighter, more race-like weight. And for many individuals running aftermarket wheels, the brakes also have to look nice, too.

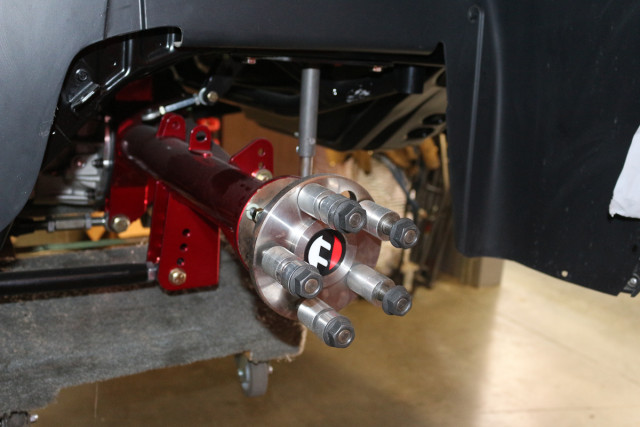

The billet aluminum brake calipers emblazoned with the company logo look as sharp as they operate. These calipers are a four-piston design to give ample stopping power from runs nearing 150 mph.

Aerospace Components has been checking these boxes off for years with its lines of brake systems for street legal applications, and when we set out to equip the four corners of our Project True SStreet Camaro with brakes that will perform regardless of the situation, we turned to their Pro Street line of brakes. True SStreet, inspired by the look and inner workings of the factory-built COPO Camaro, will be powered by a 1,000 horsepower, supercharged LSX376 engine — it’ll be fast, and whether it’s a red light or the sand trap up ahead, we’re going to want to stop it with little fuss.

What Makes A Street/Strip Brake?

The most obvious difference between a brake package for the street and one intended only for racing use is the rotor. Drag racing brakes, by and large, use a single, solid (unvented) plate rotor; this is because, as previously mentioned, the amount of time spent under aggressive load is short.

We’ve opted for solid face rotors for our combination. According to Aerospace’s Matt Moody, the solid rotors are the only choice for a road-going vehicle.

On the other hand, a street rotor is continually being heated up under normal driving conditions, and as such, must perpetually be able to cool itself. This is precisely why every car on the road features brakes with dual vented rotors. The fins in a vented rotor ‘scoop up’ air as the vehicle is moving, allowing the rotors to cool from the inside.

“If you’re driving a vehicle on the street, you should have vented-style rotors on the car, as they dissipate heat a lot better than purpose-built drag racing kits, that are designed for that use only,” Aerospace Components’ Matt Moody says.

According to Moody, the ability of a rotor to withstand heat, or rather, to fail due to heat, is a formula of heat and time combined. “If you get the rotors over a certain temperature and hold them there for a long period of time, you’re going to run a greater risk of warping them. It’s just a spike — a lot of times they can handle spikes in temperatures, but they can’t handle long-term heat.”

Where you live, in terms of traffic, frequency of stops, and the variance of elevation, will effect the operational temperature of your rotors, as Moody explains. A drag race rotor, as he shares with us, could easily be destroyed in a matter of minutes in an area with frequent red lights and traffic stoppage. “Out in the country, people that have one stoplight, they could drive a drag race brake setup every day back and forth to work and be fine, because they’re only stopping the car one time and then they let them sit and cool.”

If you get the rotors over a certain temperature and hold them there for a long period of time, you’re going to run a greater risk of warping them. – Matt Moody, Aerospace Components

Beyond the dual vented rotor design itself, you also have several different styles of rotor faces, including slotted, cross-drilled, and those that are drilled and slotted. For our needs, we opted for a smooth rotor, which is what you’ll find in virtually all production vehicles. Such a rotor provides the maximum in surface area, and as such, dissipates heat better than the slotted and cross-drilled rotors. Because they lack any machining to the surface, they also have greater structural integrity, which makes them suitable for track duty, which is exactly what we’ll be doing with them.

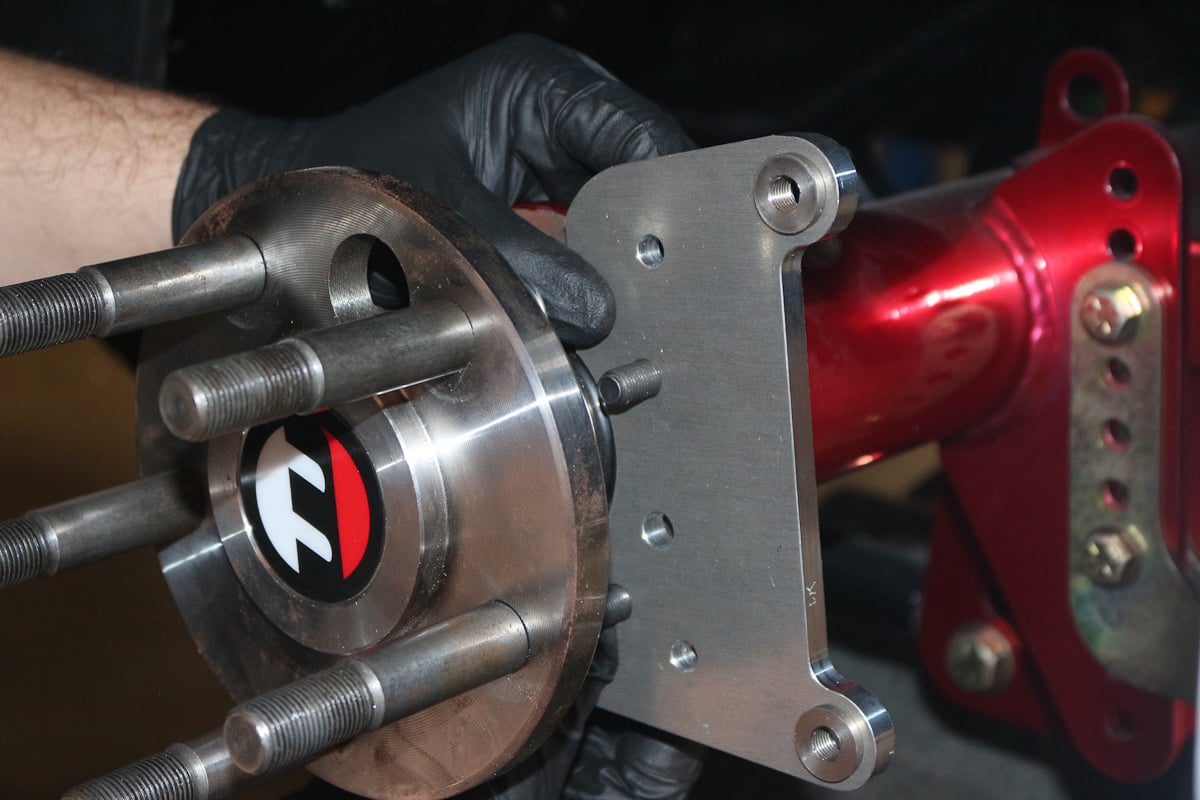

Our rear brake calipers brackets (top) and the front caliper brackets. With the front caliper mount, we’re able to use the stock Camaro spindle without any modification.

Moody shares that there are only minute differences in actual performance between a vented street rotor and a drag race rotor. The street rotors are larger in diameter, giving them more leverage under braking. The race rotors, meanwhile, use a more aggressive pad. This, in essence, nearly equals them out in terms of sheer stopping power. The simple formula, he shares is “small rotor, more aggressive brake pad.” And the weight difference is minimal, at about three pounds per corner for a vented rotor over a drag race rotor.

The stock front spindle and hub assembly. Aerospace provides a brake caliper basket that mounts directly to the OEM spindle.

Beyond the rotor diameter, and vented versus non-vented, the difference in stopping power between the solid and cross-drilled or slotted rotors is, per Moody, minimal at best – around two to three feet on a skid pad. “The drilled and slotted is often more for looks, but their downfall is that they’re harder on brake pads, they produce a lot more dust (a cheese-grader effect), and when worn past the slots, they’re thrown away, rather than being re-surfaced and reused, as a solid rotor would be,” Moody explains.

“For a car that goes to the track, a cross-drilled or slotted rotor is more prone to heat cracking, because they’re going from very cold to very hot in a short amount of time,” he continues. “Around the holes in the rotors, it’s going to remain cooler than the rest of the surface of the rotor. These hot and cold spots on the rotor are where the heat cracking will appear. On the street, you’re normally bringing the entire rotor up to temperature slowly and evenly, rather than going 150 mph and slamming on the brakes. This is why, if someone is doing a street and strip car, we try to direct them to a plain vented rotor.”

The assembly process begins by installing the rotors onto the brake hats. Aerospace provides countersunk screws for the installation.

In regards to material, Aerospace utilizes steel on its drag race brake kits because it’s better at handling the quick temperature spikes and aggressive brake pads those setups use without gouging the rotor. The cast iron street rotors, meanwhile, dissipate heat better (especially with the veins in the vented rotor).

…if someone is doing a street and strip car, we try to direct them to a plain vented rotor. – Matt Moody, Aerospace Components

Aerospace’s has Pro Street brakes for many different popular domestic vehicles from Ford, GM, and Chrysler, with several different styles of housing ends for the rear kits. They also come in smooth, slotted, drilled, and drilled/slotted rotor designs, depending upon your aesthetic needs. all are made from billet 6061 military-grade aluminum, so you know you’re getting a quality setup that’s going to last and take some abuse. A complete Pro Street brake kit, according to Moody, weighs in at about 70 to 75 pounds.

According to Moody, Aerospace’s Pro Street kits are designed to be used on the street or at the drag strip. “They’re street-duty, meaning you could drive them from one end of the country to the other without having any issues, or drive it to the drag strip and go 180 mph, no problem. That’s what they’re designed around.

Aerospace recommends the use of Red Loctite throughout the installation, including for use on the brake line.

The brake caliper bracket will mount directly to the stock spindle. With supplied shims, you can then position the calipers to the rotor.

“They’re fairly easy, bolt-on’s on the front,” Moody continues. “You simply remove the factory calipers and rotor, bolt our rotor and hat assembly together, as well as our caliper and bracket assembly, and bolt it on the car.”

After installing rotors, the calipers can then be installed and aligned with the shims (this is a fixed caliper system, meaning the pads must be close but not touch). You can then install the brake pads into the calipers.

The Install

With our move to a solid rear axle setup for drag racing, the rear brake installation is a relatively straightforward flange-mount setup.

Fifth-generation Camaros, with their factory independent rear suspension (IRS), use the same spindle front and rear, and the hub assembly itself is virtually the same, with the splines in the rear hub serving as the only major difference. That makes the development and installation of aftermarket brake packages on a stock Camaro equipped with IRS relatively simple.

However, because we’ve done away with the IRS in an effort to mimic the COPO Camaro (and just move to a more drag racing-suitable rear suspension setup in general) to a solid rear axle conversion, we’ll actually be running a standard axle and housing-mount brake system in the rear. Aerospace only recently came to market with its front brake package for the fifth-gen, which is very similar in design to its existing 1993-2004 Camaro brakes.

Up front, the Aerospace brake package uses the existing spindle and hub assembly, with no modification of the spindle necessary to mount the brake caliper (some kits for other vehicle models require you to cut the ‘ears’ off your spindles).

Like we did with the front, we slide the brake hat and rotor onto the studs and snug it down, before moving on to the installation of the caliper brackets onto the axle flanges. Once that's all in place, we can bolt on the rotors, position them on the rotor, and slide the brake pads in. Once at that stage, we can tidy up the positioning of the pads/rotor and tighten everything down, bleed the brake lines, and get the car ready for the new wheels and tires.

The installation process begins with installing the rotor onto the brake hat, using the supplied 5/16-inch low head bolts, ensuring the counter-bored side of the rotor is facing away from the hat. Then, using the supplied fasteners, attach the caliper mounting bracket and factory hub to the spindle and torque to 50 ft-lbs. From here, slide the hat/rotor assembly over the wheel studs and secure it with a pair of lug nuts.

The brake calipers can then be installed onto the spindle. Aerospace has provided several shims to position the calipers inboard and outboard, to position them directly in-line with the rotor. Install the calipers with the bleeder screw above the brake line port so the bleed is at its highest point, ensuring the caliper is centered on the rotor within .050-inches using the shims. Then drop the brake pads into the calipers and secure with the pad retaining bolt and nylock nut.

Drilled And Slotted Rotors In Drag Racing

Drilled and slotted rotors remain quite popular in drag racing-specific applications, both out of function and form. Not only do they look great, but the design keeps the rotor cool and allows the trapped gases created by way of friction between the pad and rotor to escape during operation. While more prone to stress cracking around the drilled holes, the very nature of drag racing — a relatively short but aggressive application of the brakes, followed by long periods of cool-down time — gives them plenty of longevity. In a circle track or road racing car, however, you would want to avoid drilled rotors.

From here, you can begin installing your brake lines and bleeding the system. The inlet port on these brakes is 1/8-27 pipe thread. Aerospace insists that only steel or brass fittings should be used with these brakes.

Because we switched over to the solid axle, the rear assembly is pretty standard for any race-style vehicle. The caliper bracket itself mounts to the housing end, and the caliper can go on either side of the axle, but the head of the steel insert needs to face toward the rotor. You can then install the assembled hat and rotor onto the wheel studs and snug them down.

Now, mount the caliper onto the bracket, making sure the centerline of the caliper lines up with the center of the rotor. Like the front, you’ll need to use shims to position the caliper and get the proper alignment.

Once our brake system is fully plumbed, we can move on to the wheels and tires. Now, everyone knows that a great looking set of wheels goes a long way, but they also have to be functional for the intended purpose. In our case, as we’re mimicking the styling of the factory COPO Camaro, we also wanted a wheel set that looked the part. Fortunately, Weld Racing produces a line of RTS Forged wheels that are designed for street and strip use, but carry the race styling we’re after.

The Rollers

The RTS wheels on our Camaro measure 15 inches front and rear, with a 18 x 4.5-inch, race-like width up front and 10 inch width in the rear to fit our 275/60/15 Mickey Thompson Drag Radials. The backspacing is 2.20 inches in front and 3.5 inches in the rear, with a -14 mm and -55 mm offset front and rear, respectively.

“The RTS is really designed to cover a lot of combinations, and serve as a really versatile wheel,” says Weld Racing’s Chris Bovis. “We’ve taken a modular, custom-wheel concept of construction, but manufacture them in an efficient way to hit an aggressive price point for a forged wheel, but still offer everything from skinny fronts and 15×10 drag race setups, all the way up to 20-inch large diameter, precise, custom-fit options that you would often find on wheels that cost twice as much.”

Weld’s RTS Forged wheel wrapped in Mickey Thompson ET Street Radial tires, ready to go on our Project True SStreet Camaro.

According to Bovis, the RTS was designed to be a street wheel, but it borrows heavily off the company’s drag racing heritage. The rim shells, in fact, are identical to those of their drag racing-specific wheels, so the components and design integrity of the wheel are a direct outgrowth of what Weld has learned in drag racing. “What you see in the RTS is really a street version of a full-blown drag race wheel. A perfect use of that product line is a street and strip kind of car.”

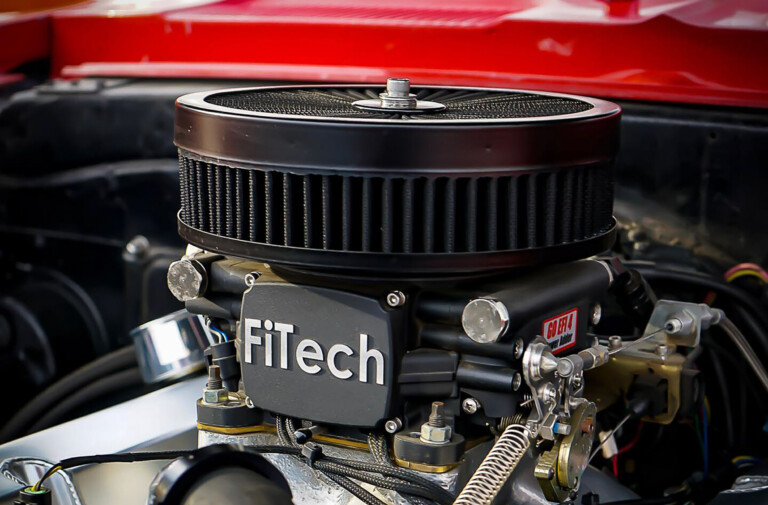

With True SStreet now rolling under its own power, it puts us one step closer to hitting the proverbial finish line, and thus the road and the drag strip. With our new solid rear axle combination bolted up, the car will be ready for some punishment on the track, while the fresh new set of brakes from Aerospace will more than deliver the adequate stopping power the car demands, be it coming to a halt after a 150 mph blast down the 1/4-mile, or merely driving through afternoon traffic, stop light to stoplight. Keep it tuned here as we bring you future updates on one of the most exciting projects we’ve ever had in the Power Automedia garage.

With True SStreet now rolling under its own power, it puts us one step closer to hitting the proverbial finish line, and thus the road and the drag strip. With our new solid rear axle combination bolted up, the car will be ready for some punishment on the track, while the fresh new set of brakes from Aerospace will more than deliver the adequate stopping power the car demands, be it coming to a halt after a 150 mph blast down the 1/4-mile, or merely driving through afternoon traffic, stop light to stoplight. Keep it tuned here as we bring you future updates on one of the most exciting projects we’ve ever had in the Power Automedia garage.