The Gen II engine is somewhat the forgotten child in the family history of the small-block V8, but here’s one engine builder who specializes in the LT1/LT4 from the ’90s and finds ways to make serious power with this neglected architecture.

Karl Ellwein of Ellwein Engines and Finish Line Engineering of Lexington Park, Maryland, sort of “stumbled” into the LT1 generation when he started racing a ’95 Impala. He had the first engine built by a local shop, then decided to assemble the next three engines on his own. Much of his inspiration came from a lengthy Car Craft article written by John McGann showcasing the LT1.

“I spent time on the phone with him and later decided to make it my niche and specialize in the Gen II,” remembers Ellwein.

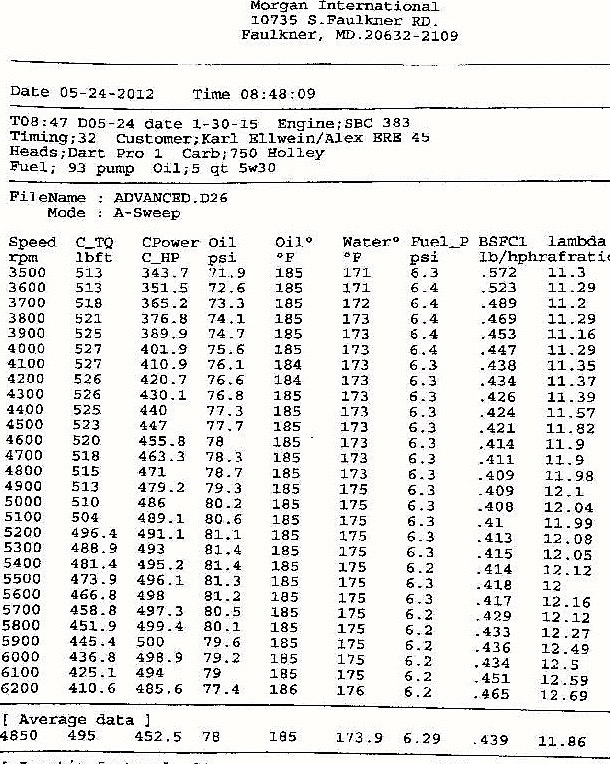

A power plant technician by day, he was also encouraged by the late Lennart Bergqvist of Autoshop Racing Engines (he won the 4th annual Engine Masters competition, then sponsored by Jegs in 2005) to treat his engine building as a legitimate business. The latest bullet from his well-equipped basement shop is a 383ci stroker that pulled 500-plus lb-ft torque from low 3,000 rpm range up to 5,100 rpm and peaked out at 527 lb-ft at 4,100 rpm. Max power was 500 at 5,900 rpm.

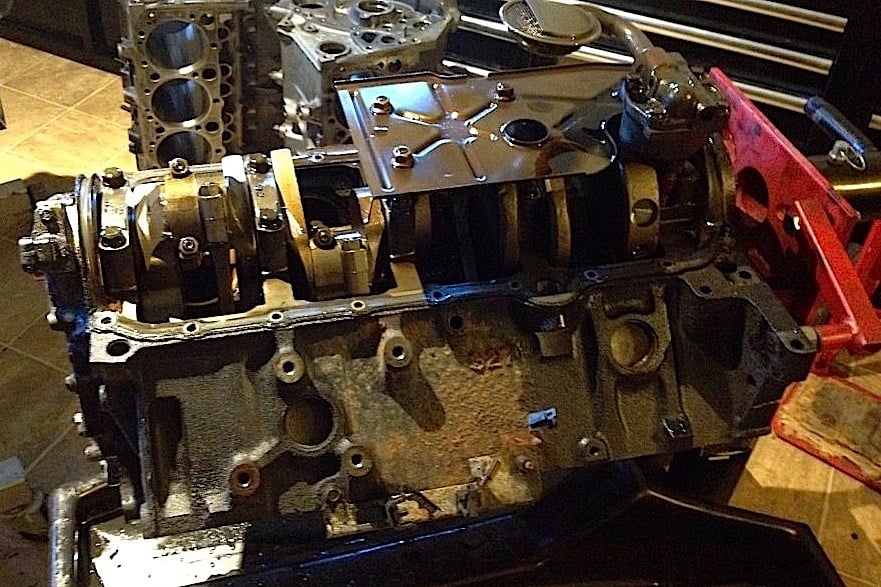

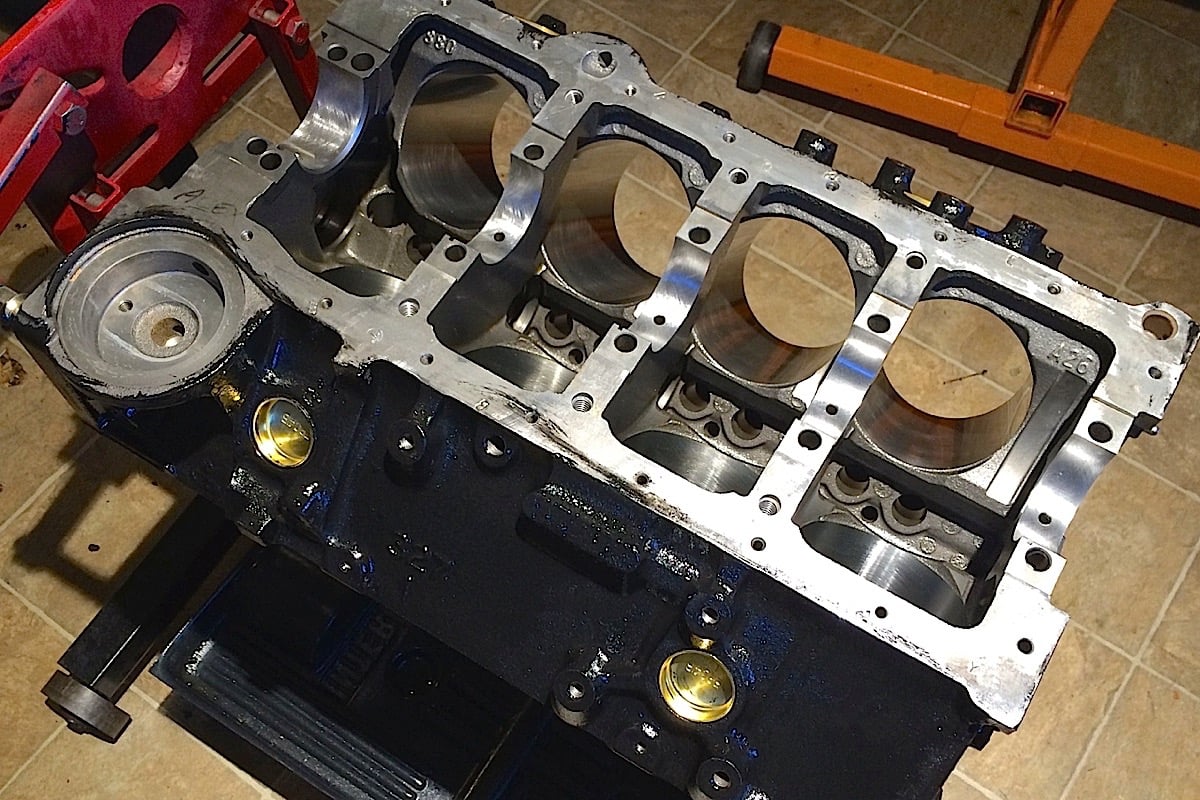

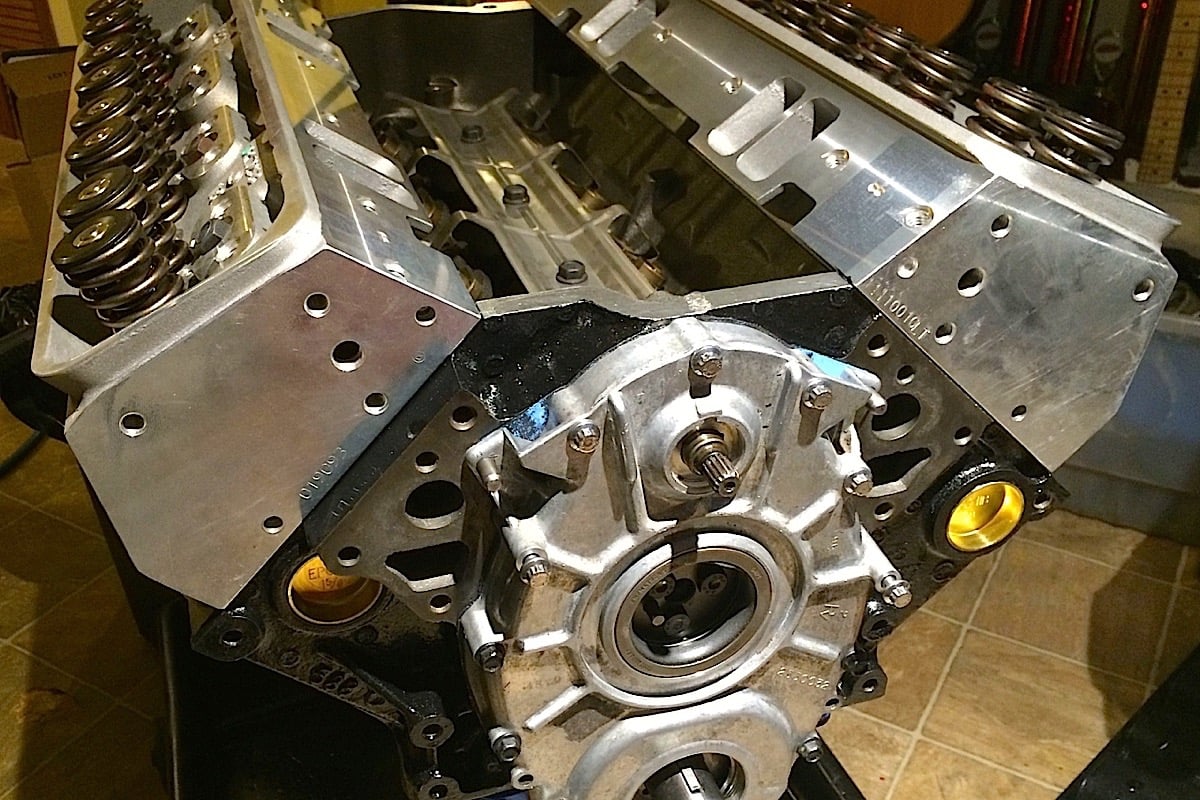

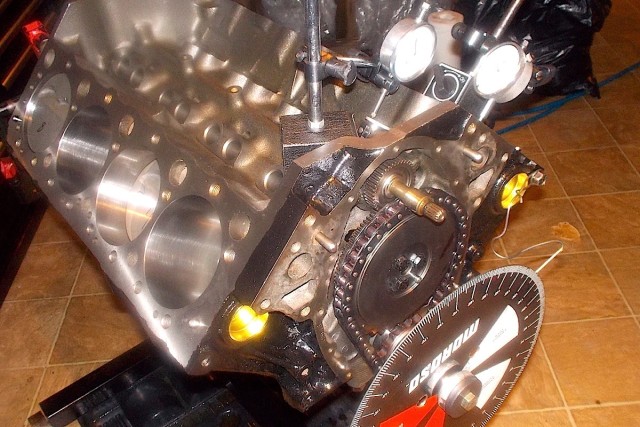

Here' how the engine looked when it came into the shop and after initial cleaning and block work.

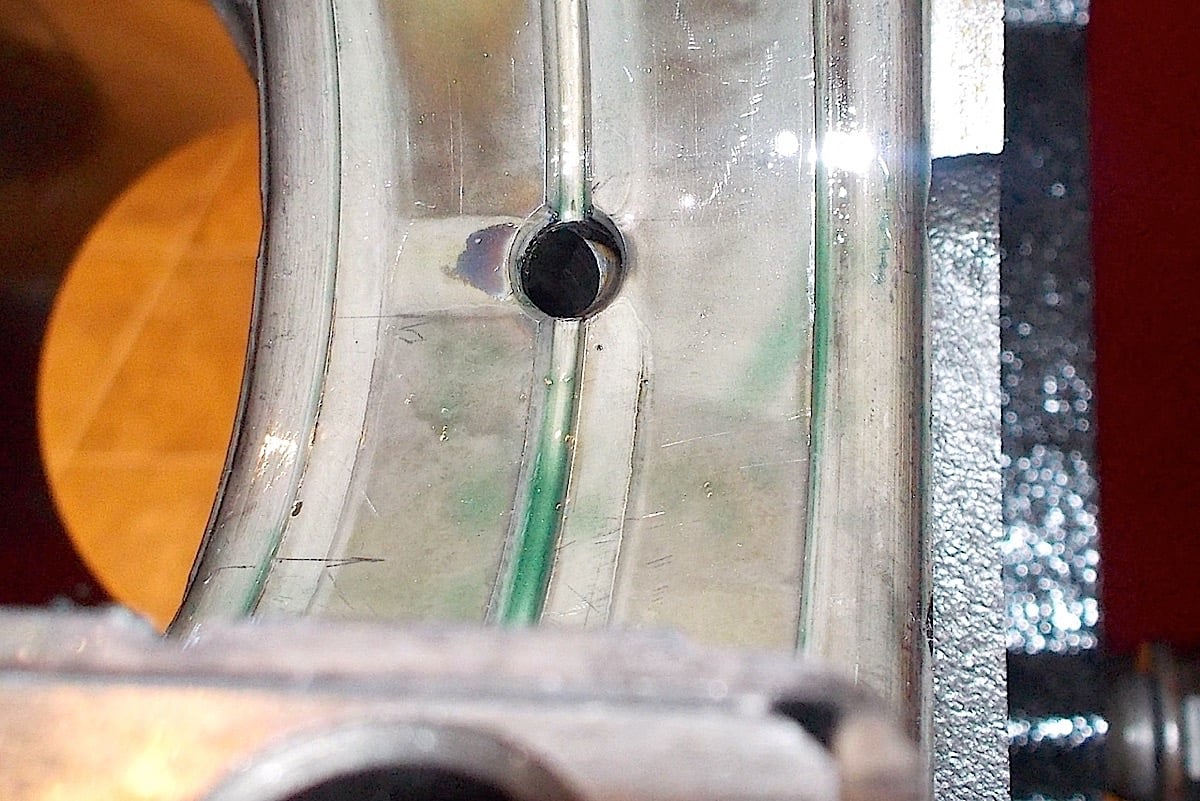

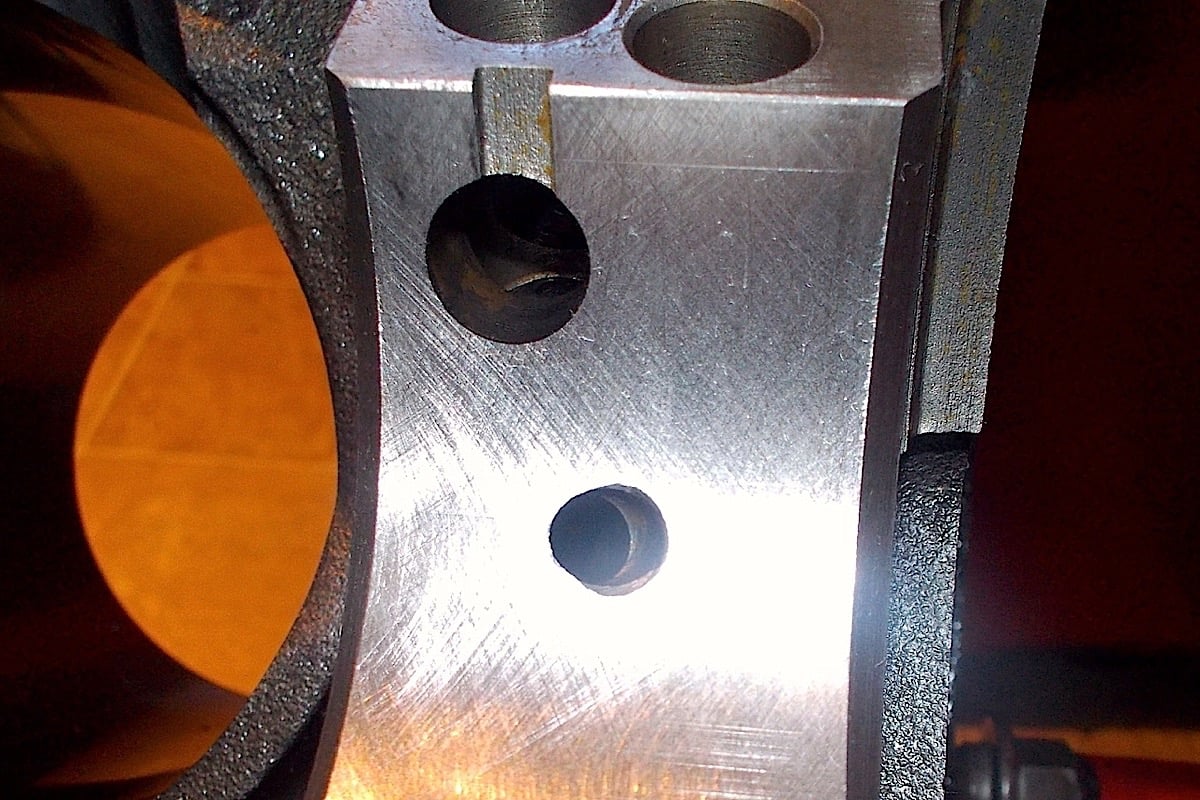

An oil feel hole was enlarged to match up with the bearing.

More power than expected

“This one was a little unusual because it made way more power than I thought it would,” says Ellwein. “I did the exact same cam and head combo about three or four years ago, but with a stock LT1 intake and FAST EFI. It made only 450 lb-ft and around 440 horsepower.”

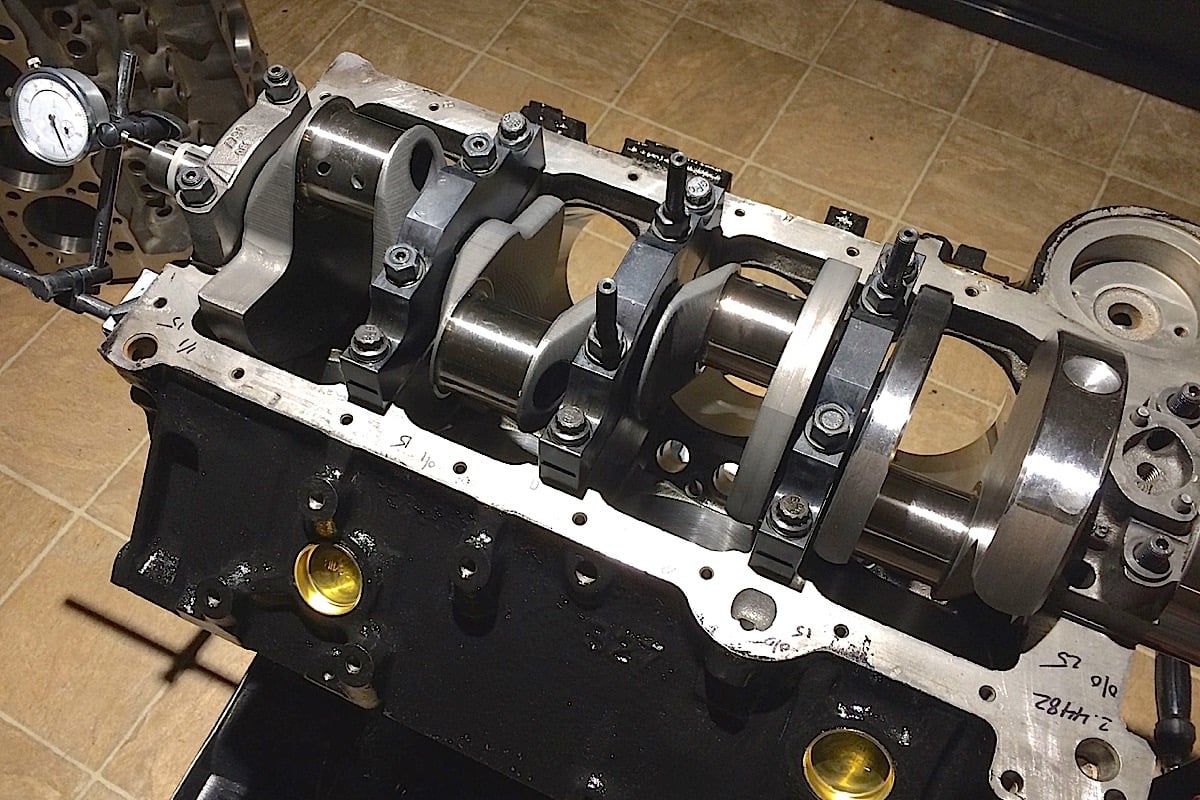

The crankshaft is from Callies. Note how the block was modified to accept billet 4-bolt mains.

More on the engine in this video later, but first a look back at the Gen II engine. Its genesis was arguably born out of frustration, and it lasted only seven model years (1992 through 1997) in select GM cars, mostly F-body and B-body applications. The trucks never wanted it. Of course, the Gen II was preceded by the original small-block that was built from from 1955 up through 2003 (It was used in trucks all during the LT1/LT4 production and early part of the LS generation.) The Gen III/IV LS engines were introduced in 1997 and still continue in some Australian models. The LT moniker has now been revived for the new Gen V platform introduced a couple years ago and is found in the Corvette and truck line. The Gen II appears almost like a stop-gap measure between the highly popular and venerable Gen I engines and the powerful LS family. What happened?

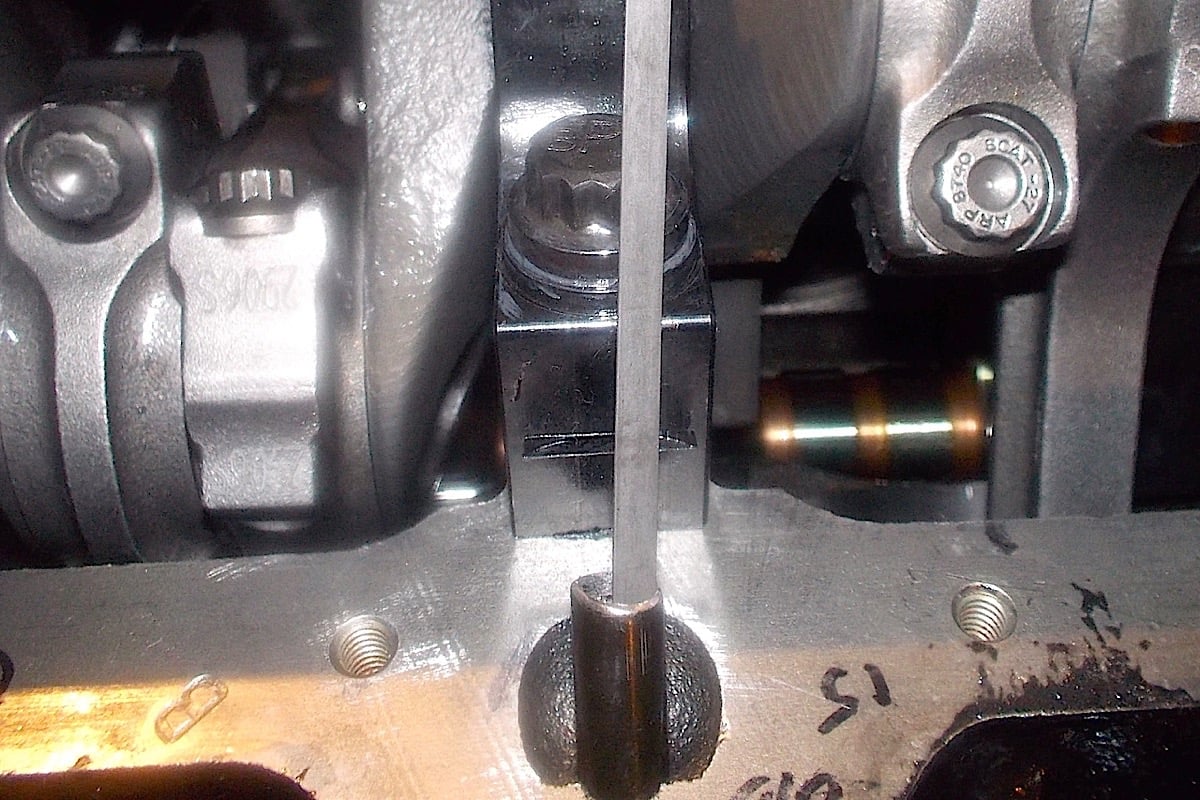

Scat rods needed a slight bit of clearance work to avoid the camshaft.

Pistons and rings are from Mahle.

Here’s a story I heard while talking with a GM engineer in the early ’90s. He said a number of powertrain engineers were frustrated that the highly visible LT5 engine project — a dual overhead cam V8 that would power the original ZR1 Corvette — was given to Lotus Engineering in England in the late ’80s. At the time, GM owned Group Lotus, which consisted of various companies sporting the Lotus brand. These engineers then started a mini skunkworks project to develop a new engine platform. According to this source, the engineers shifted budgets under the table, forged documents to scrounge parts and generally worked in the shadows to develop the LT1.

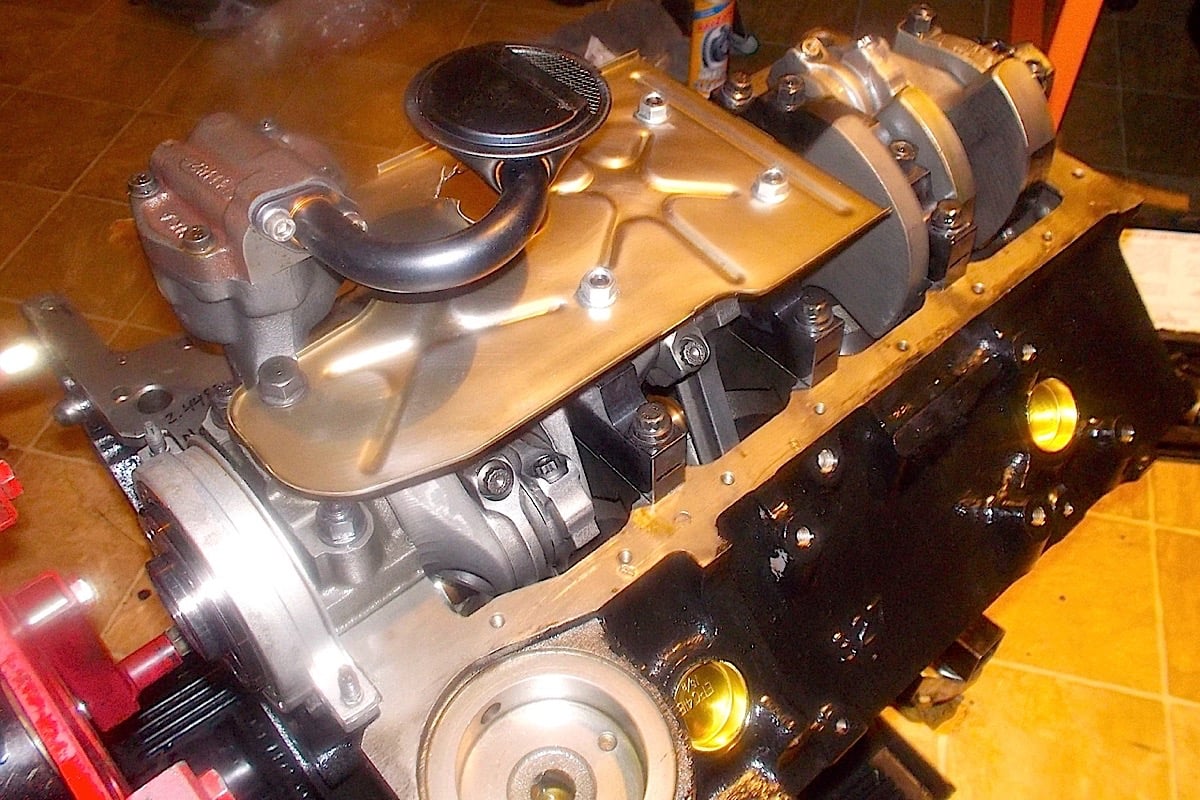

The Crane camshaft is identical to the “846” cam from the old GM Performance Parts catalog. Note the gear-driven water pump on the LT1.

Here's the bottom end nearly buttoned up before the stock oil pan (below) is installed. Note how the dipstick tube needed modification to clear the new billet cap.

Motivation to build the LT1

A couple years later I spoke to the GM official in charge of all V8 engine projects at the time. He said the LT1 development wasn’t nearly that dramatic but that there was a team of engineers set up to compete side-by-side with the LT5 program. Some information was shared, which sped up the LT1 development. However, in his highly praised book “Heart of the Beast: History of the LT5 and ZR1 Corvette,” author Anthony Young writes: “The LT5 goaded [LT1 engineers and supporters] to action, and they did not stop with the 350-cubic-inch LT1 V8 known as the Gen II, but moved onto the Gen III. It is their belief there is still a great deal of capability left in the venerable pushrod two-valve V8, and they were going to prove it.”

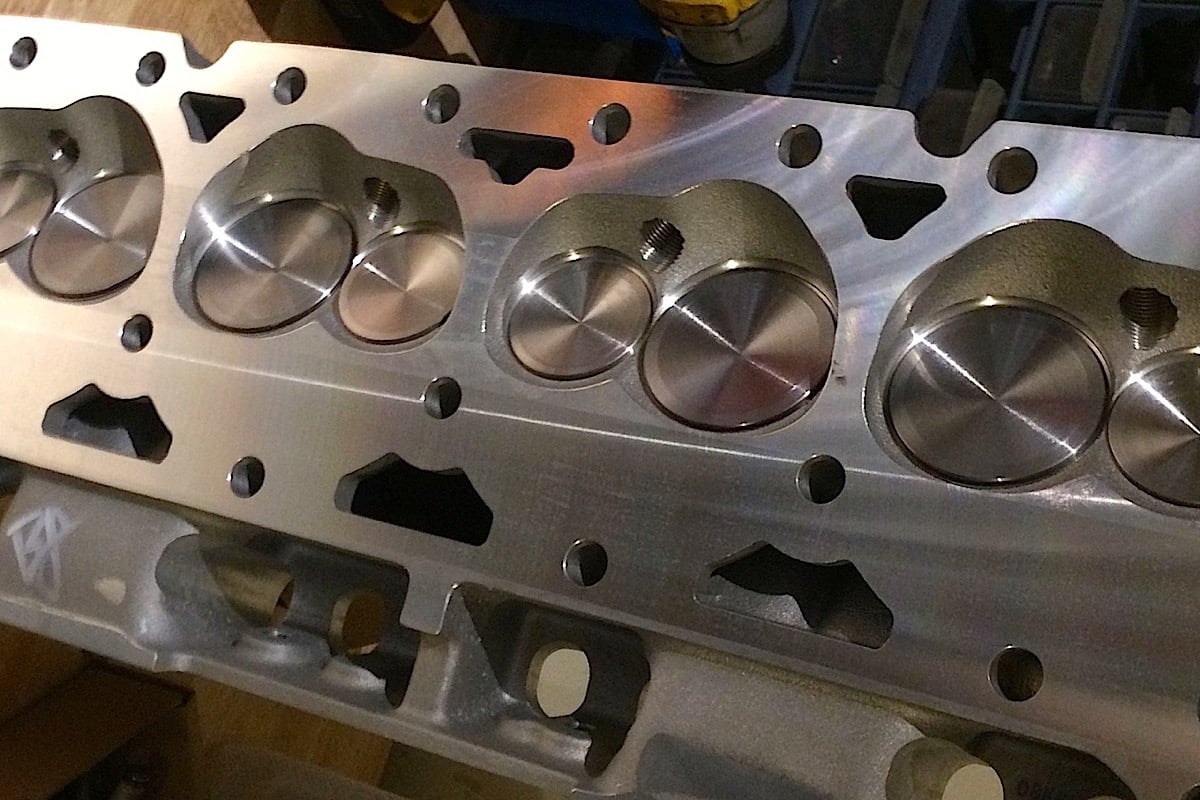

The Dart LT1 heads came fully assembled.

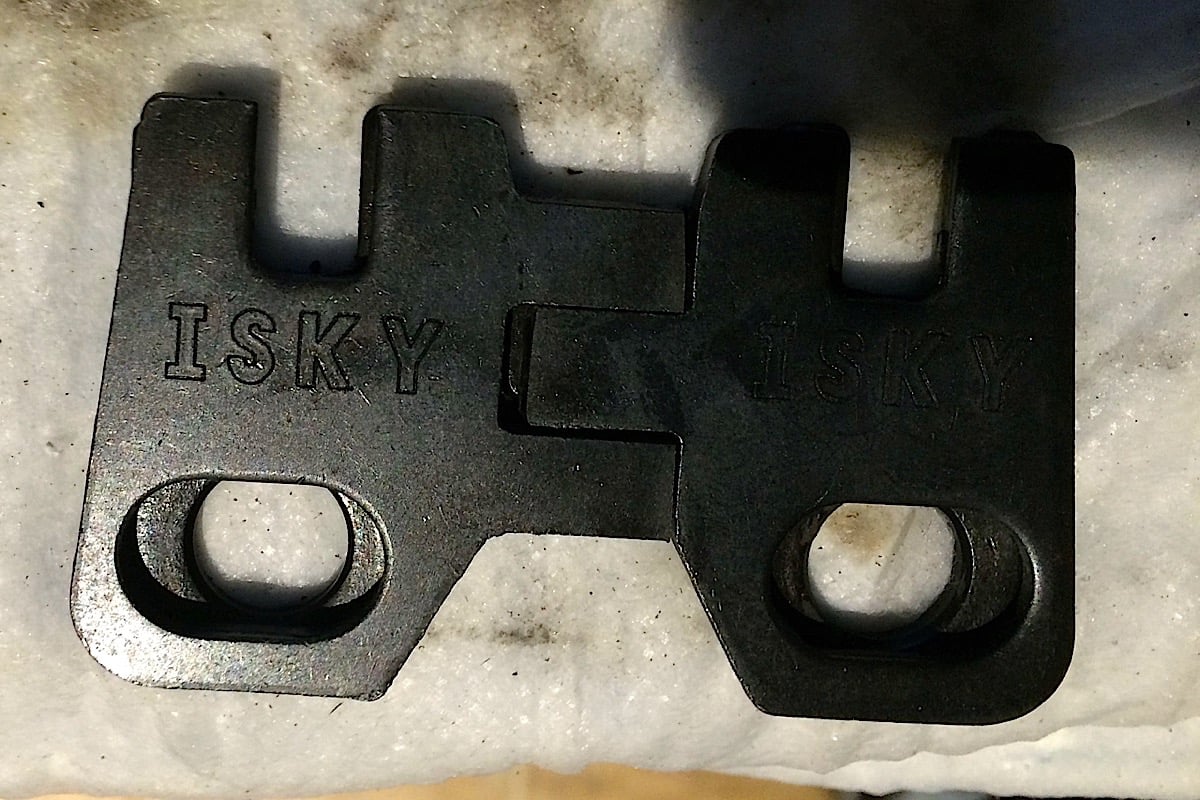

The Isky adjustable guide plates needed some trimming to ensure that the rocker arms were positioned correctly over the valve stem. ARP fasteners were used throughout the engine.

The LT1 is a good engine with advanced features like a gear-driven reverse cooling system that sends coolant to the heads first, allowing a higher compression ratio. Serving the Corvette originally, it pumped out 50 more horsepower than the Gen I L98 and still returned 25 mpg. The automotive press noticed that the LT5 option was about $30,000 but the ZR1 was only a second quicker in the quarter mile. Was it worth it? Apparently not as the ZR1 was unceremoniously dropped as a model after only a few years production.

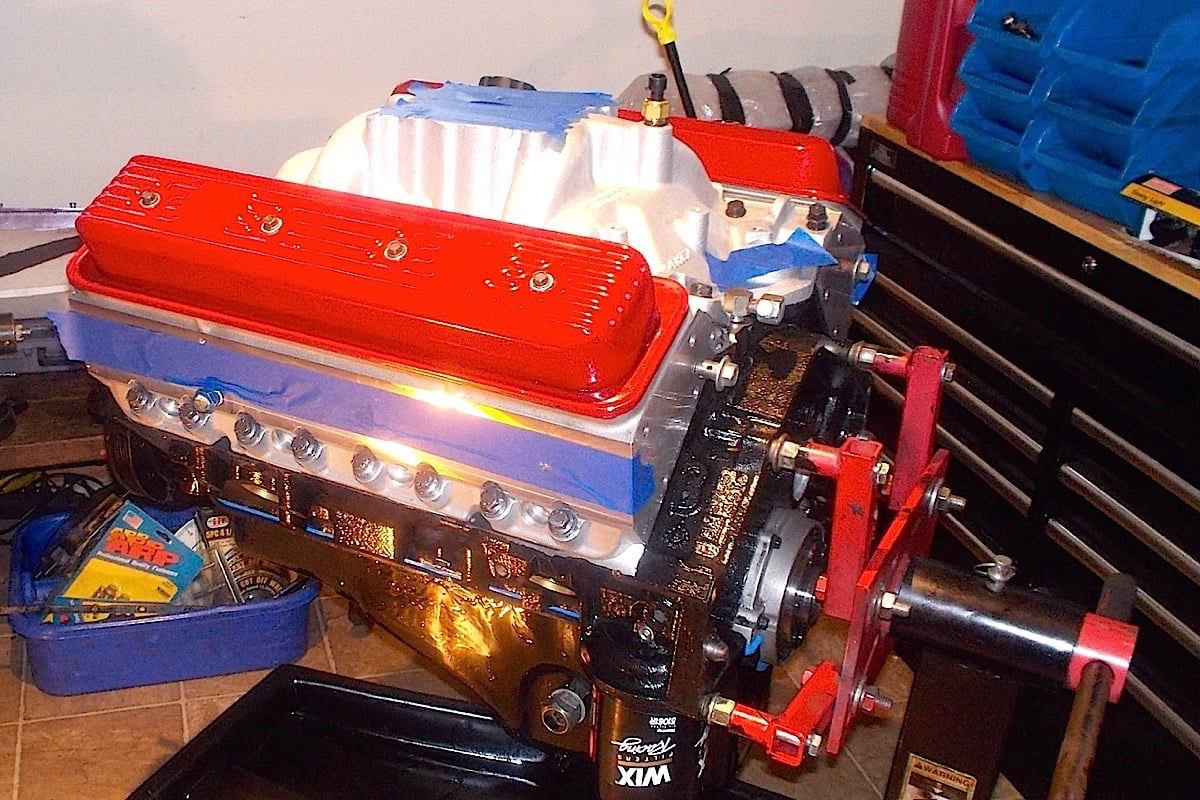

Wrapping up the build

This stroker LT1 project, codenamed ERE383 #45 in Ellwein’s shop, started with a relatively clean and straight short block. The factory crank will be good to go on a later 355 project as Ellwein opted for a 3.75-inch stroke Callies Dragonslayer crankshaft. The LT1 is quite similar to the Gen I in many dimensions, so some parts cross over — like the rods and 1-piece-rear-seal crankshafts. But the latter is getting harder to find in performance trim, says Ellwein.

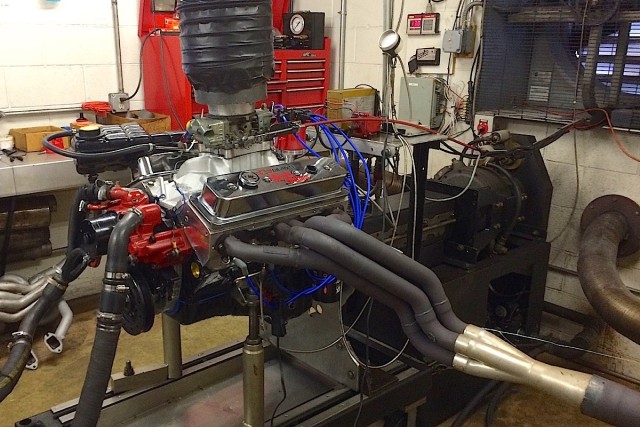

Testing was conducted with a GMPP carb intake manifold and MSD distributor.

“There are a lot of 2-piece designs but it’s tough to get a good 1-piece,” he says. “It somewhat limits me for cost-effective crankshafts.”

“There are a lot of 2-piece designs but it’s tough to get a good 1-piece,” he says. “It somewhat limits me for cost-effective crankshafts.”

Scat 6-inch I-beam connecting rods were mated with Mahle flat-top pistons (11:1 compression ratio) and rings. Clevite H-series bearings are used throughout. Ellwein had to enlarge one oil-feed hole, and the rods had to be clearanced slightly to avoid interference with the cam, which is a Crane version of the popular “846” camshaft (PN 12730846) previously offered by GM Performance. Specs are 222/230 @ .050, .509/.528 with 1.5:1 rockers, and 112 LSA. The heads are from Dart and the bottom end includes a Melling oil pump. Additional components include ARP fasteners and Isky pushrod guide plates.

The engine was tested at Morgan International Race Engines with a GM Performance dual-plane intake, Holley 750, MSD distributor and circle-track-style headers. When it goes to the customer, it will be installed in a Camaro and reunited with the stock fuel injection and ignition system.

“He’ll lose some of that midrange torque, I believe,” sums up Ellwein.