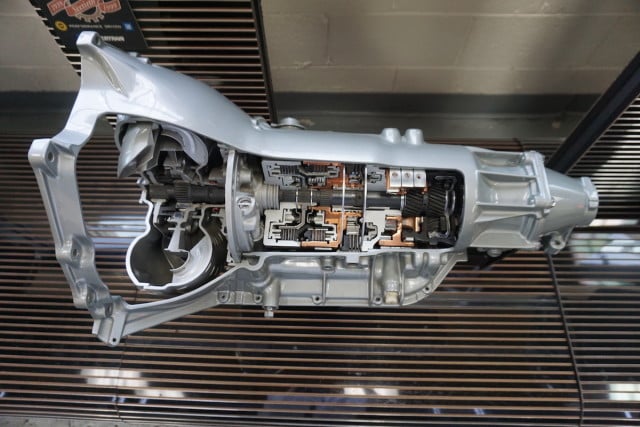

Every assembly, sub-assembly, machined part, and individual component that makes up the assembly in a Chevrolet vehicle gets a GM part number. Understanding the procedure behind the numbering system can help identify components in your project car for accuracy. Photo from wikipedia.org

When you are researching your project car for detailed information, or looking for parts at swap meets or online, understanding how GM’s part numbering system works, can help. Part numbers can be as important as cowl tag codes, VIN numbers, broadcast sheets, or protecto-plates when it comes to verifying important information like dates, revisions, or completeness and accuracy of your restoration.

Understanding GM’s part numbering system can help car enthusiasts in a great number of ways, especially when using publications that incorporate original GM part numbers in the assembly instructions or illustrations. We’ve enlisted the help of the GM Heritage Center to discover how GM numbered the parts for the vintage Chevrolet musclecars of the 1960s and early 1970s.

Part Numbers or Casting Numbers

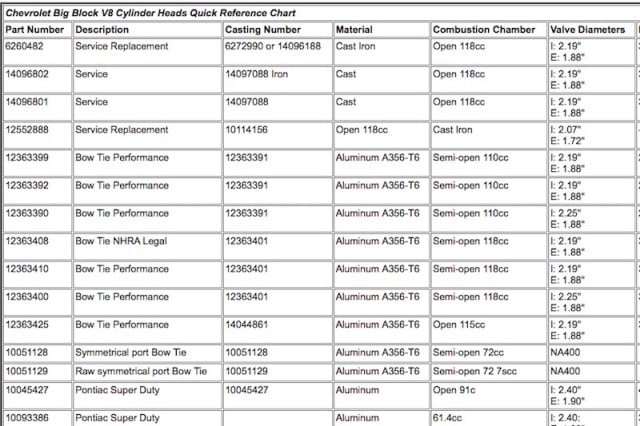

If you are like us, every piece of data is a potential gold mine of information, and should be researched thoroughly. There are times when one set of numbers leads the researcher in one direction, and another set of numbers can point in a different direction. For example, a popular “double hump” cylinder head on a 327ci Chevy made in 1968, has the number of 3917291 “cast” into the valve galley.

As most SBC enthusiasts can attest, this one casting number cylinder head was available with 1.94-inch intake valves, for the designated base 300hp V8 engine, or with the larger 2.02-inch intake valves for the designated optional 350hp V8 engine. This same casting number cylinder head was also manufactured with a hole for a temperature sending unit when used on the 1968 Corvette models. When the raw casting was machined in different ways, it carried different part numbers. Knowing the part number helps define which which type of vehicle the part was originally installed.

Keep in mind that cylinder heads are interchangeable from side to side. A component like an exhaust manifold can only be correctly installed on the left or right side of the engine. For components like these, a basic rule of thumb – odd numbers for left side components and even numbers for right side components – exists for both part numbers and casting numbers for parts that are cast. Parts that are not mounted in pairs, can have part numbers that are either odd or even.

When it comes to using either casting numbers or part numbers – we say yes, use both if you have them. Obviously if you only have the casting number or the part number, that is what you have to start your search with. The more information that you begin your search with, the better the results are likely to be.

How GM Numbered Their Parts

Our contact at the GM Heritage Center, Christo Datini, pointed us in the right direction when it came to understanding what GM’s part-numbering procedure was during the musclecar era. GM’s Engineering Specifications Prodecure, the document that provided guidance for many of the engineering areas within GM, defined the numbering systems to facilitate uniformity. As far as the part number was concerned, the procedures were put into place primarily to help prevent excessive costs and help keep the costs of the vehicles down.

About Part numbers

GM’s Central Office in Warren, Michigan, issued blocks of part numbers to different divisions as outlined in the engineering standards. According to the document, “part numbers were to be assigned sequentially and without any significance attached to the digits or their arrangement.” This may have been true in many of the different divisions, but we have noticed that several of the divisions were very deliberate in assigning the part numbers.

For example, when the Chevrolet Engineering division drew a block of numbers, they first assigned a number to an entire assembly – like a cylinder head for example. The next number sequentially would be the components that required a machining process, like the raw cylinder head casting that needed surfaced, and valve faces ground into the casting. The next set of sequential numbers would be the components that were required to complete the assembly – like the valve, valve springs, valve retainer and valve keepers.

All production parts, and service parts, were to carry GM part numbers – whether they were manufactured or purchased by GM. The only area where we can tell that these procedures differ, is where the United States government was concerned. Any GM parts that were to be used for commercial work for the government, was to be issued a separate GM part number. The government part numbers were the only ones that could have a suffix, or dash number behind the primary parts number.

Today’s Part Numbering System

While GM continues to use many of these same practices today when numbering new parts, there are many instances where the policies of the past have been ignored. A good example of this is the odd and even part numbers for components installed in pairs. In many cases on modern Chevrolets, you can find even part numbers on the left side component and odd part numbers on right side component.

GM Parts that are installed in pairs that can only fit on one side or the other have typically been assigned even part numbers for the right side and odd part numbers for the left side. Photo from www.autozone.com

We still enjoy going to the swap meet and looking for rare or unusual parts based on our crude knowledge of the GM parts numbering system of old. It makes us shudder to think how the do-it-yourselfers are going to sift though the swap meets in the future if these engineering standards continue to stray from their historical trends. Maybe they won’t even have swap meets in the future?