We wanted to change perceptions with our latest parts upgrade so we looked for a project car that was common and ordinary. Selecting a ho-hum project car that didn’t get the respect that others in the GM Camaro linage get was not difficult. The ’82-’91 F-Body Camaros are largely overlooked as a real viable threat on the street or strip. Sure, the third-generation Camaros actually brought some performance back to the platform with four wheel disc brakes and lighter weight, but governmental regulations on emission controls limited the majority of these Camaros to an underpowered 305ci engine.

Looking to restore respect in our F-body project car, we opted to go with a serious upgrade to the rearend of a 1991 Camaro RS without deviating too much from the factory designed drivetrain. While the Ford 9-inch rearend has seemingly become the universal “go-to” rearend when performance and budget are considered, the GM 12-bolt is actually a very well designed performance component, and some might even say better than the Ford 9-inch.

Moser Marketing Director Jeff Anderson explains the bottom line on their products, “Moser uses only U.S. made steel, forged in U.S. plants using Moser designed dies and tooling.” You just feel the sense of devotion to the U.S. and patriotic pride when you talk to the people at Moser. Jeff went on to explain that the company’s founder, Greg Moser, “used a team of engineers to develop the proprietary material that the company still uses today.” The company is now carried on very capably by his son Rob Moser – who grew up helping spline axles in the shop.

Bring Your Umbrella Because It’s Raining Cold Hard Facts

Here’s the real deal in the debate over rearends: the Ford 9-inch rearend is 25-30 pounds heavier and less efficient than the 12 bolt rear end. The 12-bolt’s input pinion is 1 1/2 inches below the centerline of the ring gear compared to the 9-inches 2 1/4-inch drop. Through independent testing, the 12-bolt rearend has a 3 1/2 percent better horsepower efficiency compared to the Ford 9-inch due in large part because of a reduction in friction and lubricant temperatures.

Yes, the Ford’s modular design allows for an easier change of center section and gears and the axle retainer is located so that a broken axle doesn’t result in the tire, hub and part of the axle departing the car. If you could have a more efficient rearend with the added safety factor and ease of gear change it would be the best of both worlds. We found exactly that with Moser Engineering’s 12-bolt, built-to-order rearend package.

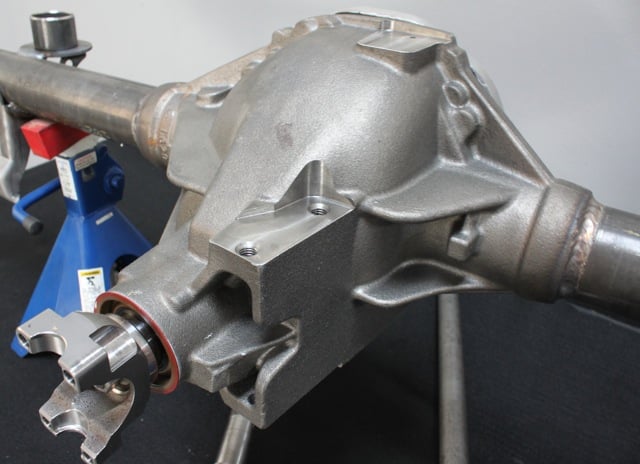

Moser Engineering's Built-to-Order 12-bolt package comes complete and ready to install. All we needed to do was press the bearing on the axles and install the 35 spline axles into the housing.

Moser Engineering Complete Built-to-Order 12-Bolt Package

The Moser’s built-to-order 12-bolt rearend package is a complete kit, and like all of the Moser rearends, built in the USA. With the supply of OE 12-bolt rearend housings drying up, “our 12-bolt housings are completely new and manufactured from Moser owned casting boxes,” says Anderson.

Key to Moser’s 12-bolt housing are design features like seamless steel 3-inch outside diameter axle tubes that have 1/4-inch wall thickness for strength. Mounting provisions on the housing are available in an endless array of combinations or you can order it without mounting brackets. When it comes to the “built-to-order” part of this package, you can “have it your way.”

In addition to the bare housing, OE factory style mounting bracket configuration is available for most GM vehicles:

- ’62-’76 Nova

- ’67-’02 Camaro/Firebird

- ’64-’72 A-Body

- ’78-’87 G-Body

- ’88-’03 S-10 (2WD or 4WD)

- ’55-’57 Chevy

- ’60-’72 C10

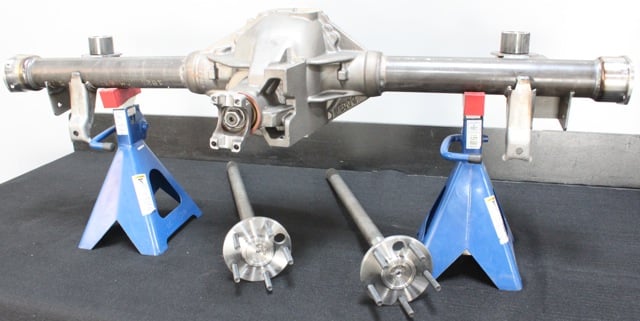

Another major selling point of Moser Engineering’s rearend packages is their custom alloy axles. The company started it’s existence with axles and over the course of their history, Moser’s axles have consistently been a source of pride for the manufacturer. Available in a choice of three very sturdy spline sets (30-, 33- or 35-spline) to match the differential’s spool.

The axles come in either the OE factory C-clip retaining or the recommended “bolt in” retainer. The bolt in axle is set up exactly like a Ford 9inch type axle configuration, and is recommended by Moser’s technical crew because of the additional safety factor. Anderson explained that, “our development team has tested the bolt in axle retainer with most type of brakes and brake backing plates to ensure there are no fitment issues. A T-bolt kit for axle mounting comes with the built-to-order package.”

Timken axle bearings, seals, and heavy duty retainer plates are also provided with the kit for the bolt in axle option. Axles are not installed in the built to order package but the Muscle Pak line of rear ends, with these same parts and options, comes delivered to your front door completely assembled.

Another option to select from is a choice in wheel studs. Starting with a 7/16-inch diameter to the common 1/2-inch stud, all the way to a very beefy 5/8-inch screw in type wheel stud. There are several options in length and knurl size, which gives the car builder a wide selection of hub and brake choices.

Stud Types:

- 7/16 x 20 -x 1 1/4-inch Press-in

- 7/16″ x 20 x 2 7/8-inch Press-in

- 12mm x 1 1/2-inch Press-in

- 12mm x 2 1/2-inch Press-in

- 1/2 x 20 x 1 1/2-inch Press-in

- 1/2 x 20 x 3-inch Press-in or Screw-in

- 1/2 x 20 x 2-inch Screw-in

- 5/8 x 18 x 2-inch Screw-in

- 5/8 x 18 x 3-inch Screw-in

- 7/16 x 20 x 1 3/4-inch Disc brake stud

- 1/2 x 20 x 1 3/4-inch Disc brake stud

Give Us A Brake

The Moser built-to-order package gives you an unlimited array of options in braking. From the OE stock drum or disc brakes to Moser’s line of disc brakes kits or virtually any aftermarket brake manufacturer’s offering. There are options for specialized brake kits like Wilwood’s drag racing brakes or a monster 11-inch Master Power Big Drum brake kit.

Brake Options:

- Set up for using stock drum brakes

- Set up for using stock disc brakes

- Wilwood disc brake kit – Pro Street with internal parking brake

- Wilwood disc brake kit – Pro Street no parking brake

- Wilwood disc brake kit – Drag racing

- Moser economy disc brake kit with parking brake

- Moser economy disc brake kit – no parking brake

- Drum – 11-inch Master Power big drum brake kit

- Drum – 9 1/2-inch GM drum brake kit

ABS Options

Installing an aftermarket rearend into a late model vehicle can pose some challenges, especially when the car is outfitted with ABS wheel sensors. Moser Engineering has taken that into account with the built-to-order package by offering OE mounting for ABS wheel sensors. For the 12-bolt rearend kit the following OE options are available:

- 3-Channel (’93-02 Camaro/Firebird)

- 4-Channel 53 Tooth (’93-97 Camaro/Firebird)

- 4-Channel 47 Tooth (’98-02 Camaro/Firebird)

- 3-Channel For use with Spool (’93-02 Camaro/Firebird)

- 4-Channel (’93-02 Camaro/Firebird)

Housing Ends

The choice of axle type and brakes has an effect on what type of housing end (axle tube ends) that come with the package. Using aftermarket brake kits can dramatically affect your choice in housing ends, as well as the option of bolt end axles. Moser recommends consulting your brake manufacturer before ordering your built-to-order rearend kit so the correct housing end is welded on the axle tubes.

Differentially Speaking

When it comes to the 12-bolt’s differential, Moser also has a variety of options. Everything from a full spool to the newest weapon in the arsenal, the 35-spline Wavetrac differential. Moser has offered the Eaton posi, Auburn and Truetrac differentials in their rearend kits for several years. Each of these are still available in 30-, 33- or 35-spline options to match the axles in the package.

Differential Options:

- 30-spline spool

- 33-spline spool

- 35-spline spool

- Eaton Posi – 30-spline

- Eaton Posi 33-spline with aftermarket spider gears, clutches & springs

- Truetrac 30-spline

- Truetrac 33-spline

- Auburn 30-spline

- Auburn 33-spline

- Wavetrac 35-spline

Ring and Pinion

One of the biggest complaints that the Ford 9-inch guys make against the 12-bolt is the limited choice of gear ratios. With Moser’s built-to-order package, that problem has been answered with a huge selection of choices in ratios. The variety of choices in this kit are large enough to cover any type of application, on any track, on any day.

Gear Ratio Options:

- 3.08:1 Ratio – Pro/Street

- 3.42:1 Ratio – Pro/Street

- 3.73:1 Ratio – Pro/Street

- 3.55:1 Ratio – Pro/Street

- 3.90:1 Ratio – Pro/Street

- 4.11:1 Ratio – Pro/Street

- 4.30:1 Ratio Pro/Street

- 4.56:1 Ratio Pro/Street

- 4.88:1 Ratio Pro/Street

- 5.14:1 Ratio Pro/Street

- 5.38:1 Ratio Pro/Street

- 4.11:1 Ratio – Pro/Comp (Drag racing only)

- 4.33:1 Ratio Pro/Comp (Drag racing only)

- 4.56:1 Ratio Pro/Comp (Drag racing only)

- 4.88:1 Ratio Pro/Comp (Drag racing only)

- 5.14:1 Ratio Pro/Comp (Drag racing only)

- 5.38:1 Ratio Pro/Comp (Drag racing only)

- 5.57:1 Ratio (Pro/Comp (Drag racing only)

- 6.00:1 Ratio (Pro/Comp (Drag racing only)

The Yoke’s Not On You

A choice of pinion yokes is also available in the package. You can select between the stock Camaro type 1310 series yoke or the beefier 1350 series yoke. If you really want a trick piece, Moser offers a 1350 series yoke in aluminum. For a normal upgrade on a vehicle that isn’t destined for track use on slicks with huge horsepower, the 1310 yoke will suit nicely and will fit the OE driveshaft length without a problem. Anderson clarified the yoke choice by saying, “if you are throwing a lot of muscle at the rearend and have some tires with serious grip, you may want to consider the 1350 series yoke.” The aluminum version of the 1350 series yoke is a nice touch to remove some rotating weight in a dynamic component.

Finishing

Nothing beats an upgrade that looks like an upgrade so Moser offers the 12-bolt rearend package with a choice of finish. The standard option is a bare metal finish for those guys that want to paint it themselves or go with the rugged manliness of a bare metal finish. Those that want a tough powder coat finish have that option but it will add two or three days to the delivery time. Moser’s 12-bolt also has appearance options for the rear cover to set it apart from a stock rearend and inform everyone behind you that this is no ordinary rearend. Optional Chrome or Black powder coating on the rear cover sends that message.

Color options for powder coating:

- Flat Black, Semi-Gloss Black or Gloss Black

- Flat Red, Semi-Gloss Red or Gloss Red

- Flat Silver, Semi-Gloss Silver or Gloss Silver

- Flat Orange, Semi-Gloss Orange or Gloss Orange

Deciding on a 12-Bolt or 9-inch

Moser Engineering rearends have made either the GM or Ford style rearends a great choice when upgrading your project car, so you really can’t go wrong. However, there are some well known facts that can help you decide. The 12-bolt Eaton Posi is a very strong unit, and allows for more tunability than the Ford OE Traction-Lok. The Chevy Posi uses two spider gears while the Fords use four, but the Ford’s are more likely to shatter than the Chevy units. Unless you are going full out, hard core, Top Fuel racing, a Chevy 12-bolt rearend will probably fit the bill and keep your drivetrain in the GM family.

Our Build

For our Project Respect Camaro, we were looking to keep it somewhat true to the GM engineer’s original design. The Moser 12-bolt rearend package, complete with 35-spline axles was the way to go. Selecting the F-Body housing with OE style factory mounts proved to make the install easy and simple.

Because we were installing a Baer Brake kit, we opted for the Torino (big bearing) style axle tube housings. Our choice of gear ratio was the 3.73 Gear Motive (Part #7110), combined with the 35-spline Wavetrac differential. This combination would handle all the power that we could throw at it without ripping the rubber off the carcass and still get us out of the hole and down the chute.

Installation

Moser’s built-to-order 12-bolt comes assembled with the sole exclusion of the axles. Much to the delight of our shop dawgs, the axles and bearings are shipped not assembled as part of the rearend. This is done to allow for any brake backing plates or emergency brake cable mounts that need bracketing at the housing ends.

Completed rear suspension set up included QA1 F-body shocks that fit into the OE factory mounts perfectly.

Our shop techs had the bearings pressed onto the axles and the axles installed in the housing in no time flat. From there it was a matter of mounting the Baer brake kit and reattaching the previously installed Spohn links, panhard bar, torque link and sway bar.

Shocking the Upgrade With QA1 Shocks and Eibach Springs

Moser’s Jeff Anderson explained to us that using “good quality shocks and springs enhances Moser’s purpose designed 12-bolt rearend, taking full advantage of the engine supplied torque.”

We wanted to cap off our upgrade with a set of QA1 Shocks and struts to really take advantage of the rear end swap. With all the traction that the wheels would be getting, we wanted to control the weight shift to maximize the traction to the back wheels.

We bolted on a pair of QA1 Gen F rear shocks (Part #TS704) to our Moser 12-bolt rearend. These are aluminum bodied shocks that have a 12-position valve adjuster that allows changing the rebound and compression simultaneously. We selected these because they can handle daily driving, street/strip drag racing or road racing. To put simply, these shocks can handle whatever you want to subject your car to. The QA1 shocks are revalvable and rebuildable, plus they fit the factory mounting locations.

Shocks and springs work hand-in-hand for suspension control whether braking, accelerating or yanking and banking around corners. Eibach Springs are a great fit with QA1 shocks and we were going to take advantage of the serious traction control that this combination would provide us.

Eibach’s Sportline performance springs offers a race style performance in traction while lowering the chassis between 1.7- 2.3-inch while still providing a street performance quality ride. Lowering the car’s center of gravity helps with body roll in corners and nose dive under braking. Eibach’s progressive spring design is set up to balance high performance with ride quality, lowering and high performance. We opted to mount the Eibach Sportline performance springs (Part #4.0138R) to our project car with dreams of doing some canyon carving in the Southern California hills.

Handling Torque With a Torque Arm

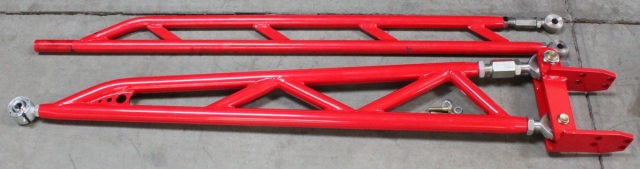

Our project car had ready been upgraded from the flimsy factory torque arm to a Sphon Performance tubular version (Part #399), which was a pretty beefy replacement that mounts to the transmission extension housing. Torque arms that attach to the transmission housing are very good at increasing straight line traction and reducing wheel hop in cars rated around the 450-500 horsepower range. Above that and the cast transmission housing may be subjected to stresses that could cause cracks in the housing.

Our project car already had a Spohn Torque Arm installed (Top) but we were bumping up the power to the point where we needed Spohn's Pro-Series Torque Arm (bottom).

Knowing that we were shooting for the 700 and better horsepower range, it was a smart move to upgrade to a cross member mounted torque arm so that the rear end and pinion angle could be set while we were doing the rearend upgrade. Spohn’s Pro-Series adjustable torque arm for T700R4 transmissions (Part #301PS) was the optimal choice to mate with the heavy duty rear end and our future fire breathing powerplant. The Pro-Series kit includes the transmission crossmember required to support the transmission, complete with a driveshaft loop.

Features of the Spohn’s Pro-Series Adjustable Torque Arm For T700R4 transmission:

- Attaches to the rear axle and controls rear end torque during acceleration, transferring this energy into the tires, increasing straight line traction

- Reduces nose-dive during braking

- Eliminates wheelhop

- Increases sidebite during corner exit acceleration

- Bolt-on system does not require complete interior removal as with other kits

- No fabrication, welding or drilling required – 100% bolt-in installation

- Removes the torque arm pivot point from the rear of the transmission to the supplied crossmember

- Changes the instantaneous center and leverage point from stock

- Provides adjustable pinion angle

Overview

Project Respect made a huge gain into the respectability range with a Moser 12-bolt rearend swap, complete with a set of high strength axles and some heavy duty gears and diff. Add in the QA1 Gen-F shocks and Baer brakes, and our project car is set for performance.

Until we figure out what engine combination will take the respectability up another notch, we are happy to have a solid drivetrain and suspension upgrades. Just looking at the car on the ground after the upgrades brings a satisfaction knowing that the third Gen is shaking off the Rodney Dangerfield role.