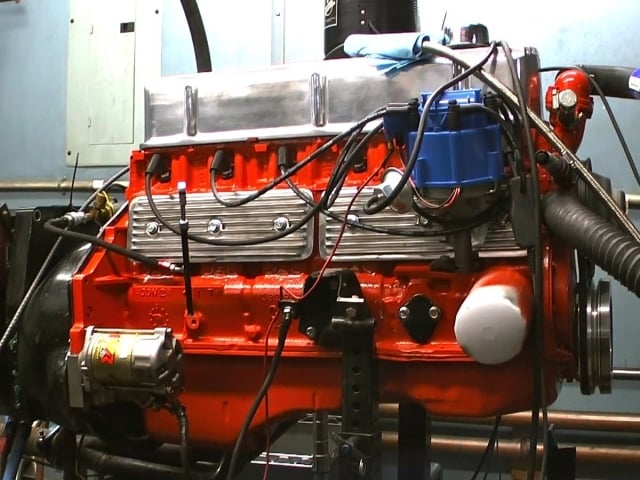

If you thought the Chevrolet straight-6 engine was a boat anchor, think again. Bob Heckt at Heckt Power Products in Dysart, Iowa, put together this street stormer for a customer’s ’68 Chevy 2WD short-box pickup using a variety of stock and aftermarket components.

“The customer is restoring the pickup and wanted to stick with the original straight-6 engine,” says Heckt. “The guys at 12bolt [2] supplied us with custom-built Ross [3] pistons and 6-inch connecting rods. The block is zero-decked, the rotating assembly is balanced, and the cylinder heads use the lump ports from 12bolt installed.

“We used a 1.94 intake valve and 1.60 exhaust valve, gasket-matched and ported the heads along with a lot of bowl work,” continues Heckt. “The intake port lumps (which were machined by 12bolt.com) help with high-rpm flow, as the stock casting has very flat port floors and then the charge runs right into the valve. With these installed, the air/fuel mixture goes up and over the hump and then down to the valve, more like a V8-style head. It helps to line the air up straight with the valve instead of coming at it sideways.”

Since the customer is planning on winging this beast to the 7,000 rpm range (!), Heckt also installed a set of dual valve springs to control the valvetrain. “We took it to 6,600 rpm and still haven’t reached the peak horsepower. We’re still messing with it here. One of the best pulls out of it so far is 320 horsepower at 6,400 rpm, running 89 octane pump fuel,” he says.

The engine has a custom-ground camshaft from Crane Cams [5] with a wide lobe-separation angle, as there are plans to potentially install a hit of the giggle gas atop the engine when it’s back in the truck. Heckt also installed Crane’s High Intensity bleed-down lifters along with 3/8-inch heavy-wall pushrods and Pontiac guideplates to combat valvetrain instability. In addition, a set of Comp Cams [6] custom 1.75-ratio Pro Magnum rocker arms were installed to help achieve their airflow goals. A Clifford [7] intake manifold and Edelbrock [8] 500cfm carburetor provide the incoming air/fuel charge.

“The really cool thing about this engine is that it has a totally flat torque curve. It starts at 265 foot-pounds around 2500 rpm and goes up to 290 foot-pounds of torque and holds that all the way up into the 6,000 rpm range. It’ll surprise a few people,” says Heckt.

A neat, out-of-the-ordinary engine that makes a boatload of power and torque – it’ll be a fun driver for sure!