Fishing for a topic to present at a technology conference, well-known engine builder Jon Kaase decided to stick his finger in an intake runner.

“I always wanted to see what it felt like inside the port and how strong were the pulses,” says Kaase, who presented a series of videos that documented his experiences in the dyno room–some of which were picked up by an attendee and recently posted on YouTube. “Was it just theory or can you really feel it?”

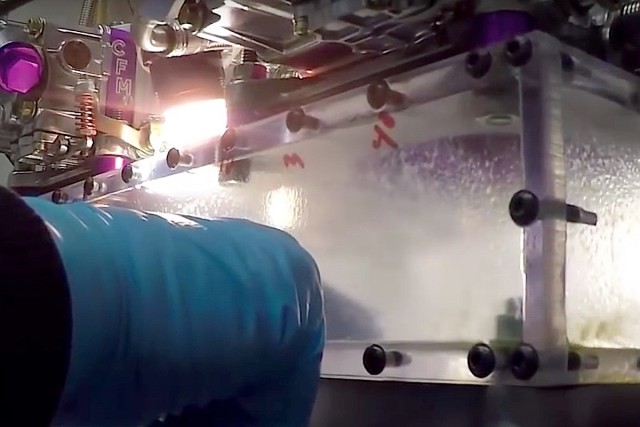

Here is the clear intake runner and access port that Kaase installed on a tunnel-ram intake manifold to physically test the intensity of the pressure waves.

Kaase was invited to speak at the 2015 Advanced Engineering Technology Conference held just before the PRI Show last December.

“Sometimes you an use [the invitation] for an excuse to learn something,” adds Kaase, who is a multiple winner of the Amsoil Engine Masters Challenge.

Kaase’s plan was to set up a trusted 521ci BBF dyno mule with a tunnel-ram intake manifold that was modified by replacing part of one runner with a clear polycarbonate tube that would allow photography. He also bored a small access port to the tube and O-ringed it just enough to allow his finger to slip into the airflow.

“You can film it all you want but nothing beats feeling it,” says Kaase.

The dyno was set up for a 3,000 to 7,000 rpm sweep.

“When it’s idling you feel a little back pulse coming up. It’s a reversion pulse when you have a big cam,” says Kaase. “You’re going to get a little bit of a pulse when the piston is changing direction and both valves are open.”

The drama started when the dyno operator dropped the hammer.

“When you go wide open, that pulse kind of disappears around 3,000 to 4,000 rpm. From about 4,500 on up you start getting a shock wave that you feel with your finger, and it starts bending your finger back and forth,” continues Kaase. “There’s no way you can hold it steady. It’s that inertia pulse that’s traveling back up the port when the valve closes–the third pulse they’re always talking about. It’s really strong.”

Those designing intake manifolds are keenly aware of high and low pressure waves inherent in the airflow dynamics of an engine. When the intake runner length, cross-sectional area and shape are all properly “tuned,” engine builders can take advantage of these dynamics to push more air into the cylinder. That’s how some engines can actually achieve volumetric efficiency greater than 100 percent without mechanical boost.

There are basically three types of pressure waves in action with every cylinder firing. One is caused by the action of the piston. Another is generated by exhaust scavenging. And a third is caused by the intake valve closing. These waves can be negative pressure waves that work their way up the intake manifold to the plenum and then are reflected back as positive waves. The key is to tune the intake runners so that the positive waves hit the intake valve just as it opens or right before it closes to get a little extra air-fuel charge into the cylinder.

“Everybody uses [the pressure waves] to their advantage,” says Kaase. “That’s why intake manifolds are the length that they are.”

For Kaase, he was just curious as to their intensity.

Fuel can be seen collecting on the port as well in the plenum in the videos, and Kaase says that’s ‘typical.’

“Of all the stuff we learned, when the engine gets up to 5,000 rpm you really can’t tell which way the flow is going,” says Kaase. “It almost feels like there’s more flow going back up then going in.”

Kaase even tried to insert his finger sideways to see if he withstand higher rpm.

“I thought I was going to dislocate my knuckle,” quips Kaase.

Kaase did take the P51 cylinder head and tunnel-ram to the flow bench and turned it on full blast, again sticking his finger into the access port.

“All it did was bend your finger down pretty good. You could feel the air rushing by,” says Kaase. “But on the engine you don’t feel the air rushing by. You feel the shock waves going back and forth.”