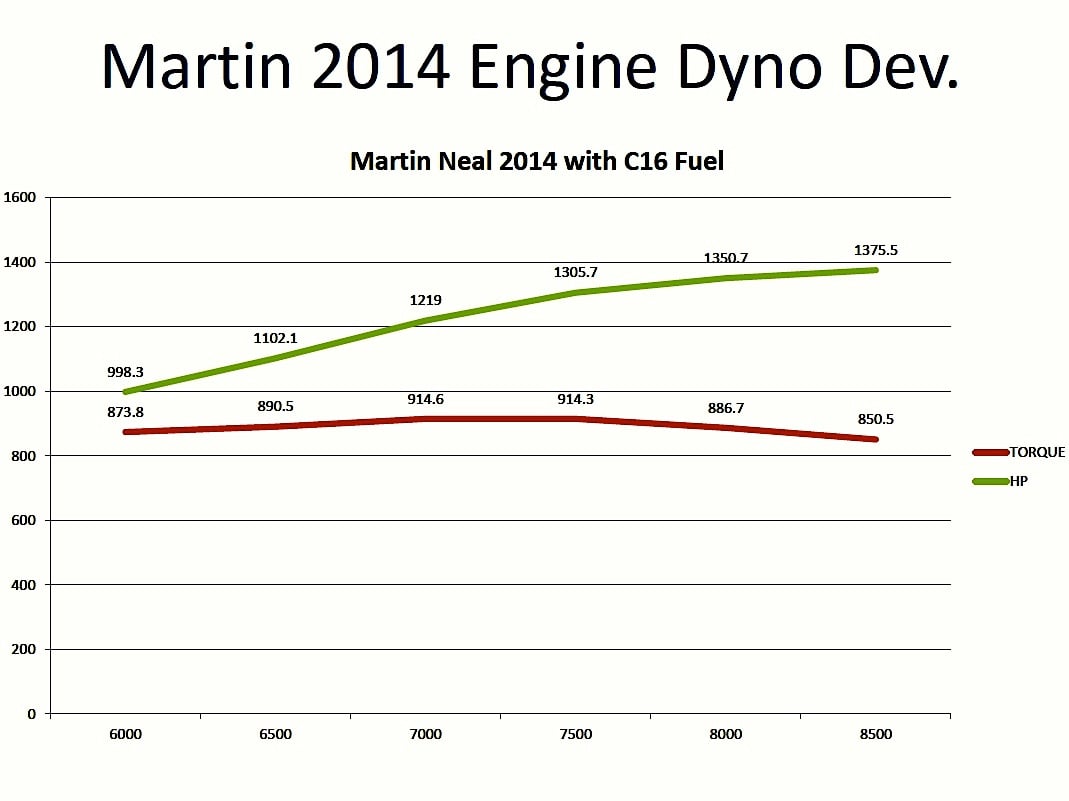

The value of a dedicated engine program is clearly evident when reviewing the progress of Neal Racing’s 582ci Top Dragster engine. Working with Harold Martin at Martin Motorsports, Jack Neal’s big-block Chevy picked up about 200 horsepower with a combination of new cylinder heads, more efficient intake strategy, optimizing specific components and fuel testing. But the performance didn’t come from just new or more expensive parts. Rather, the team set goals, kept records, worked closely with suppliers, tested often and, most important, took a few chances.

“We had difficulty harnessing all the new-found power,” admits Neal, who campaigns the East Coast-based dragster with son Paul behind the wheel. “We currently in the process of building a new car more matched to the power level.”

“We had difficulty harnessing all the new-found power,” admits Neal, who campaigns the East Coast-based dragster with son Paul behind the wheel. “We currently in the process of building a new car more matched to the power level.”

Throughout the 2009-2012 seasons, the 582 picked up about 50 horsepower with mostly tuning adjustments. But over the next winter break, power increased from 1,223 up to 1,369.

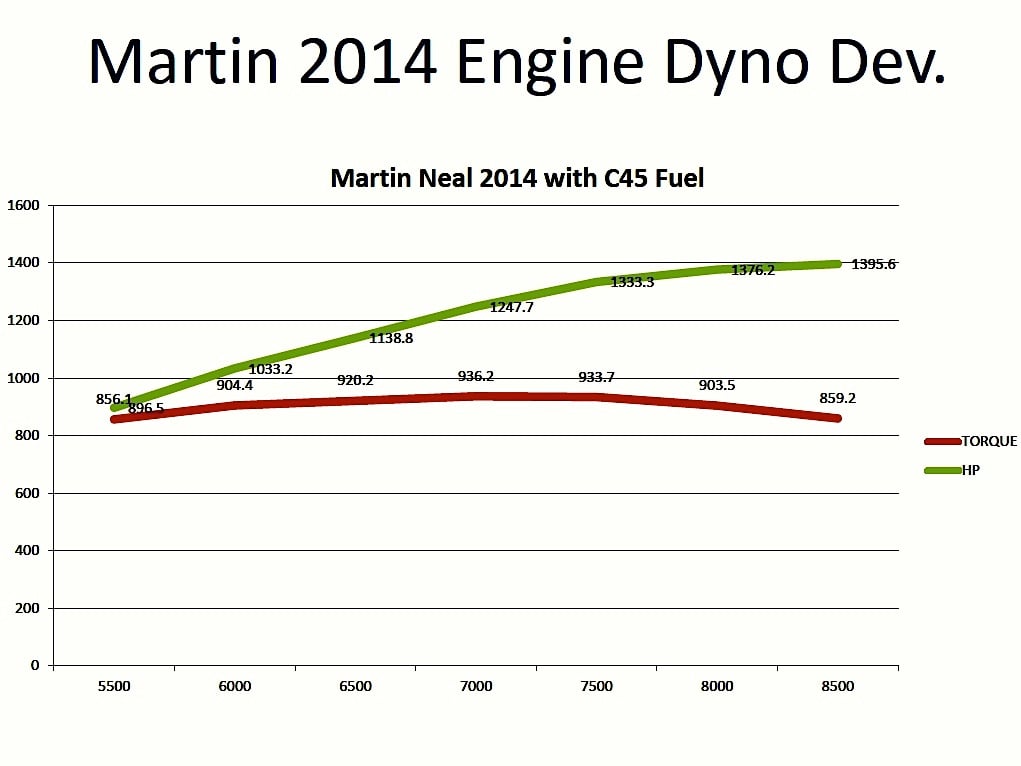

“The car’s performance went from a best of 6.91 at 193 mph to 6.68 at 199 mph,” adds Neal, noting the major goal over this past winter was testing VP’s new C45 fuel and almost eclipsing the 1,400 power mark.

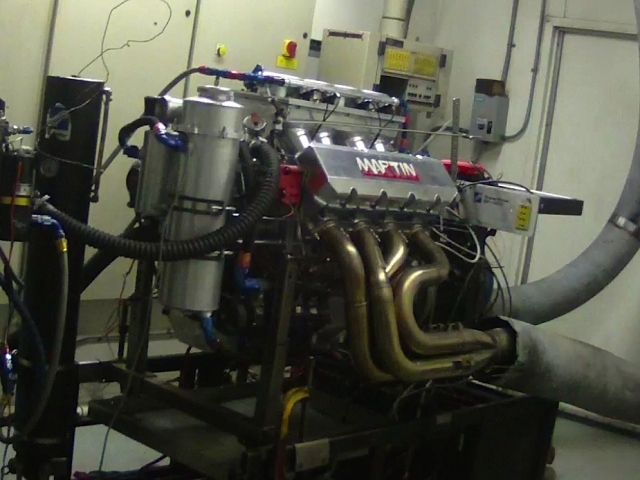

Unique to the engine is the intake manifold with an inline 4-barrel throttle body that was designed at Martin Motorsports.

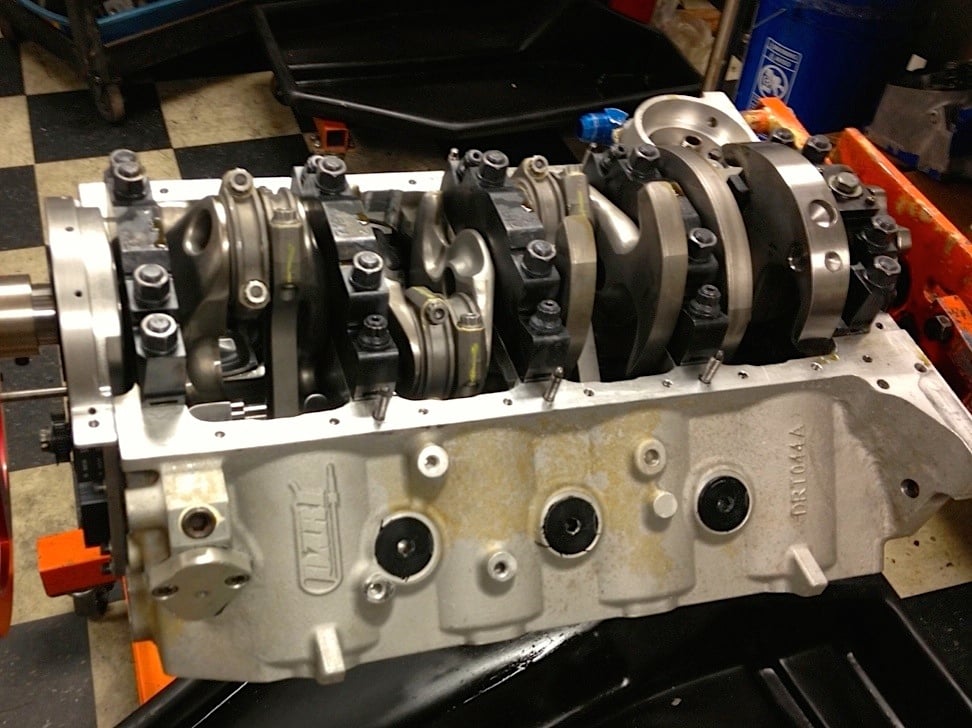

The engine is based on a Dart aluminum block with a 9.800-inch deck height and standard cam location. Bore is 4.600 inches, and the Callies Magnum XL crank swings with a 4.375-inch stroke. Crower .250-long titanium rods, Diamond billet pistons that provide a 15.35:1 compression ratio, Trend DLC pins and Total Seal .043/.043/3mm rings round out the rotating package. The short-block was assembled with Clevite bearings, Fel-Pro gaskets and ARP hardware.

“The major change came in the winter of 2012/13 when we upgraded the cylinder heads,” remembers Neal, noting that he had worked with Martin as early as 2003 on fuel-injection issues. “We gave him the reins for a complete engine program at this juncture. We started with cylinder head selection.”

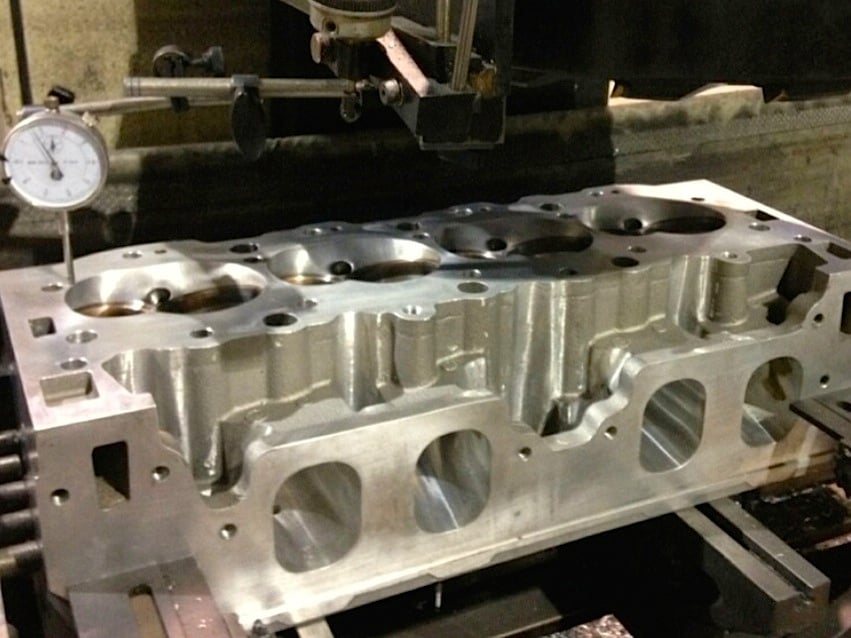

Based on a close working relationship between Martin and MBE Cylinder Heads out of North Carolina, the team chose a set of 11-degree Dart Big Chief head ported and assembled by MBE. Resulting flow reached 564 cfm in the intake and 364 cfm on the exhaust side. The heads were also stuffed with Victory 2.520-inch titanium intake valves, 1.800-inch exhaust valves and PAC springs.

“Martin commissoned HRE to build an intake manifold, and then he finished with a single inline-4 throttle body and injector placement. Martin also worked with Bosch-Europe on the development of the injectors,” says Neal, noting that the injectors are positioned high in the manifold’s plenum. “This is to take advantage of the atomizing fuel’s ability to dissipate heat in the intake air charge.”

Comp Cams ground the 55mm cam core to Martin’s specs with a non-traditional 1-8-7-3-6-5-4-2 firing order. The block and heads were clearances to accept Trend tapered pushrods (9/16 intake, 5/8 exhaust). Completing the valvetrain were Jesel shaft-mounted rockers.

“They were not lightened,” adds Neal. “Martin’s approach is to have strength in the valvetrain, not just to decrease deflection but in order to keep the valvetrain happy and improve longevity.”

Various views of the engine during assembly.

Martin reworked the oil-pan rails on the block to achieve tighter tolerances and help seal up the Moroso dry-sump pan. He also blueprinted the 5-stage pump. Other engine features include MSD digital ignition with Jesel belt drive, Moroso wires, Kook’s stainless-steel 2.375-2.500 step headers.

Martin developed the engine management system and optimized the programming to take advantage of VP’s new C45 fuel. Tests showed a significant difference of between 20 and 36 horsepower from 5,500 rpm up to 8,500 rpm over VP’s C16 fuel.

And the team still isn’t finished with engine development.

“A new camshaft was designed, based on the observations of last year,” sums up Neal. “It’s Martin’s belief that the new cam profile will enhance on-track acceleration.

Various views of the engine during assembly.